Automatic dust cleaning and placing type dust collector

A dust collector and automatic cleaning technology, which is applied to chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as troublesome operation, time-consuming and labor-intensive operations, and hidden dangers to the health of operators, so as to improve operating efficiency and reduce secondary pollution. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

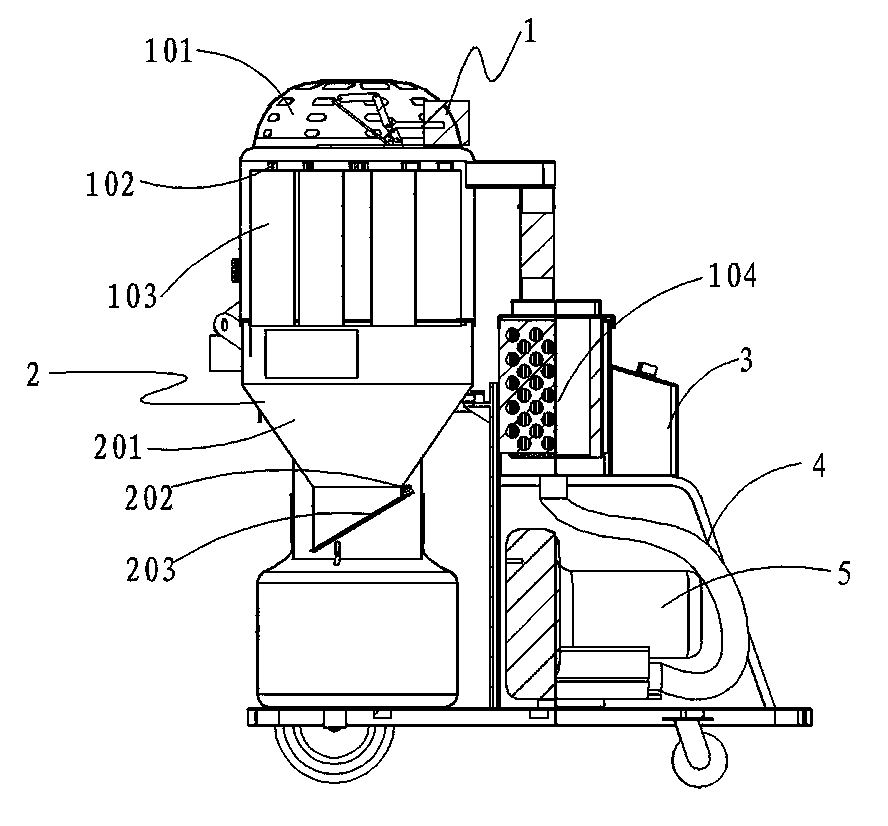

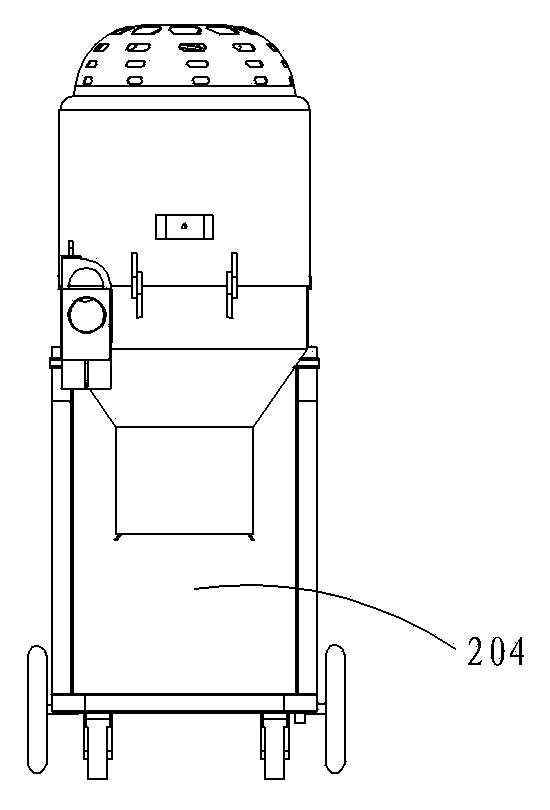

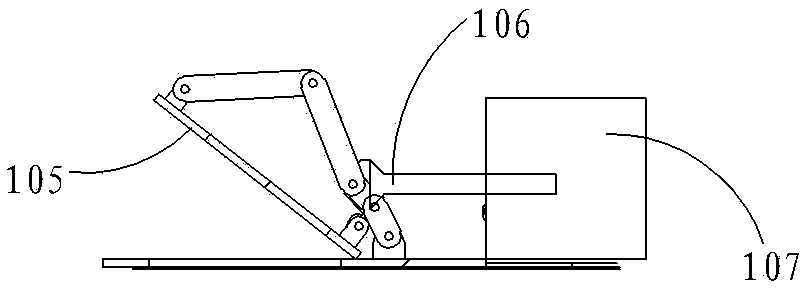

[0015] Such as Figure 1 to Figure 2 As shown, the automatic dust-cleaning and dust-releasing dust collector is mainly composed of a frame 4, an electric control box 3, a dust collecting device 1 and a dust releasing device 2, and the dust releasing device 2 is located at the lower part of the dust collecting device 1 , the dust collection device 1 is made up of a primary filter device, a secondary filter device, a dust collection bucket 103 and an electromagnetic control assembly; the primary filter device is located in the dust collection bucket 103, and the primary filter device is composed of two or more The filter element 102 is formed, and each primary filter element 102 is installed on a special fixed plate in the dust collection bucket 103 and sealed and bonded together; the secondary filter device is connected with the dust collection bucket 103 through a dust collection pipe, and the secondary filter device It is also connected with the dust collection fan 5; the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com