Automatic gauge control (AGC) self-adaptive control method for hot rolling mill

A technology of self-adaptive control and finishing rolling mill, applied in rolling mill control device, metal rolling, metal rolling, etc., can solve the problem of low control precision of strip head thickness, improve the overall thickness control precision and improve quality Grade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

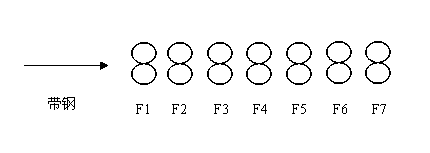

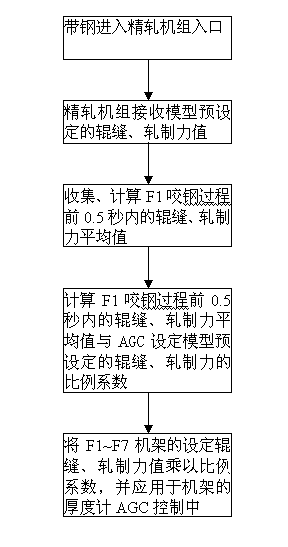

[0016] The present invention takes 7 groups of continuous finishing mills as an example, with reference to figure 1 , 2 , in the AGC self-adaptive control method of the hot continuous rolling finishing mill, select a stand at the front end of the finishing mill as the automatic control system to collect and calculate the actual roll gap and rolling force value of the stand and the roll gap and rolling force set by the model The scale factor of the value is the key point of this technique. In the present invention, this front-end frame is optional, if there is abnormality in the roll gap and rolling force detection equipment of F1 frame, it will cause inaccurate self-adaptive function, at this moment just can choose F2 frame as front-end machine frame, the self-adaptive function is automatically adjusted to correct the set roll gap and rolling force of the F2 ~ F7 frame; if the front end frame is F3, the set roll gap, The rolling force is corrected; and so on, whichever rack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com