Water circulation sealing component on trunk-type rewinding machine

A sealing component and wire take-up technology, applied in the field of water circulation sealing components, can solve problems such as poor mechanical sealing effect, and achieve the effect of ensuring the normal production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

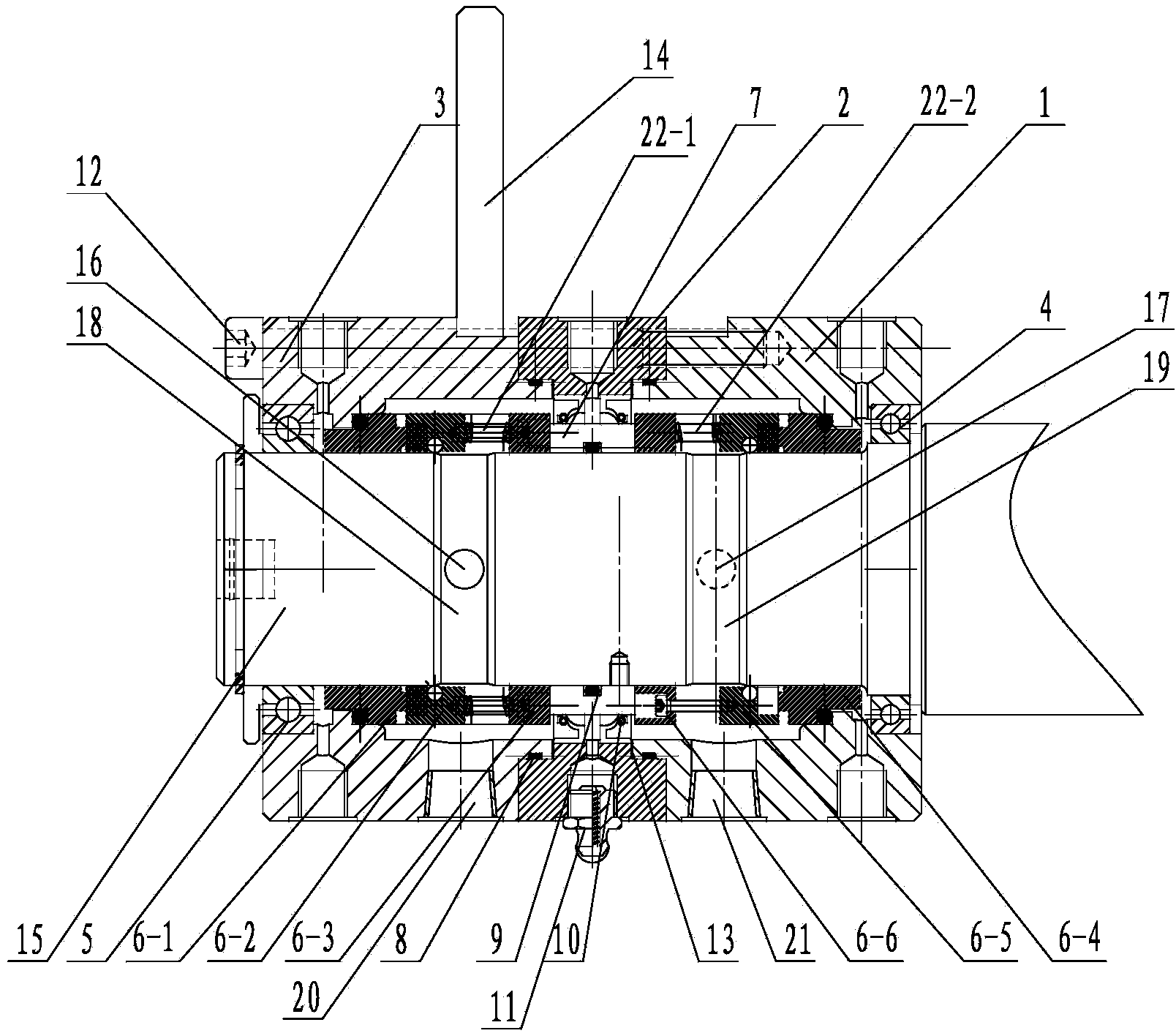

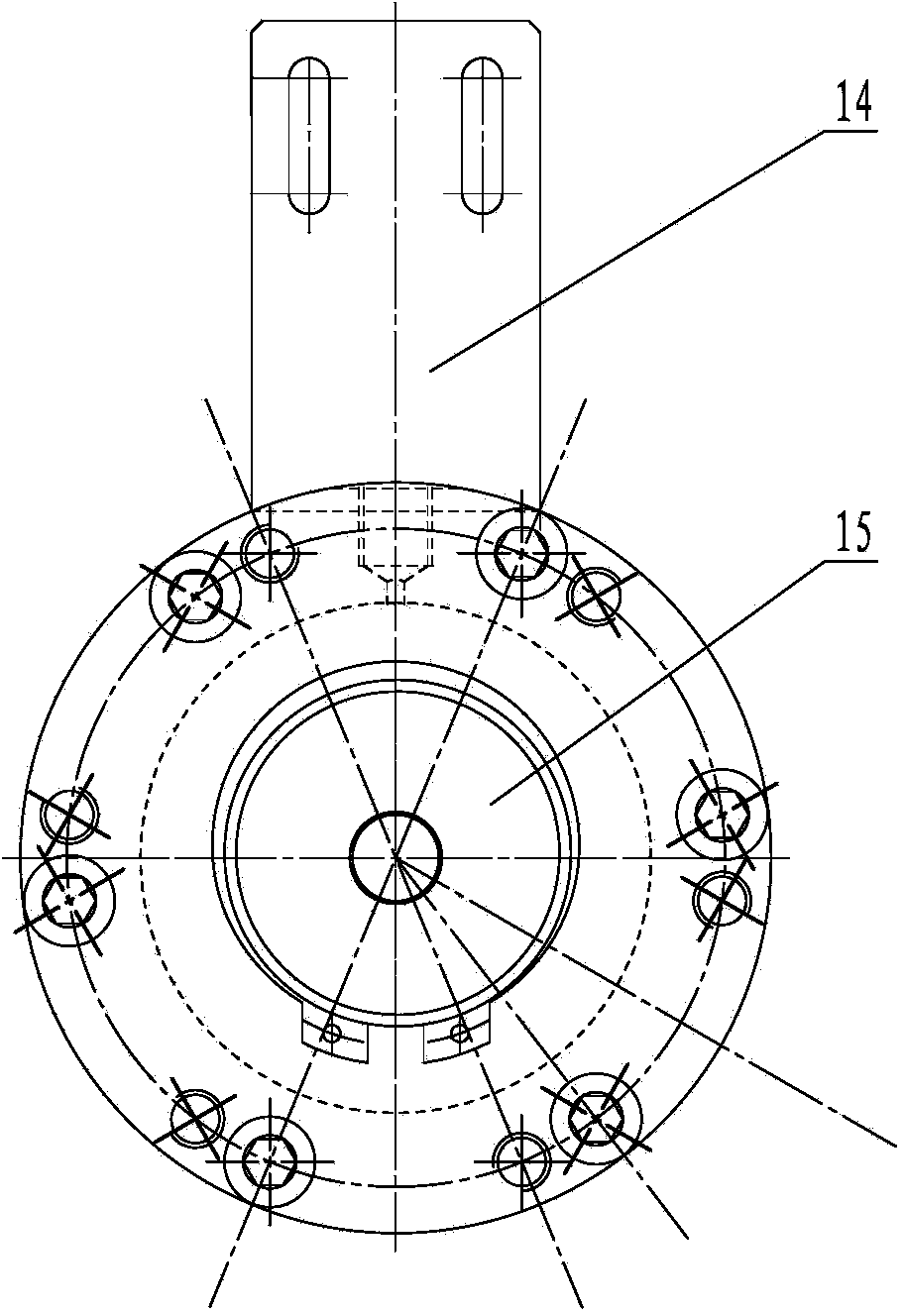

[0014] The present invention will be further described below in conjunction with specific drawings.

[0015] like Figure 1 ~ Figure 2 As shown: the water circulation sealing parts on the elephant trunk type wire take-up machine include the rear seal seat 1, the middle seal seat 2, the front seal seat 3, the first deep groove ball bearing 4, the second deep groove ball bearing 5, the first seal seat Part 6-1, second seal 6-2, third seal 6-3, fourth seal 6-4, fifth seal 6-5, sixth seal 6-6, sealing steel ring 7, The first O-ring 8, the second O-ring 9, the skeleton sliding seal 10, the oil nozzle 11, the screw 12, the sealing paper pad 13, the limit plate 14, the main shaft 15, the circulating water inlet 16, the circulating water outlet 17, the water inlet Annular groove 18, water outlet annular groove 19, water inlet connection hole 20, water outlet connection hole 21, first bolt 22-1, second bolt 22-2, etc.

[0016] like figure 1 , figure 2 As shown, the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com