Safe steel ladle lining and building method thereof

A technology of safety lining and ladle, which is applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc., can solve the hidden dangers of permanent layer ladle pouring material not being able to resist the erosion of molten steel, melting of ladle lining, and safety production and other problems to achieve the effect of eliminating ladle leakage accidents, improving service life and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

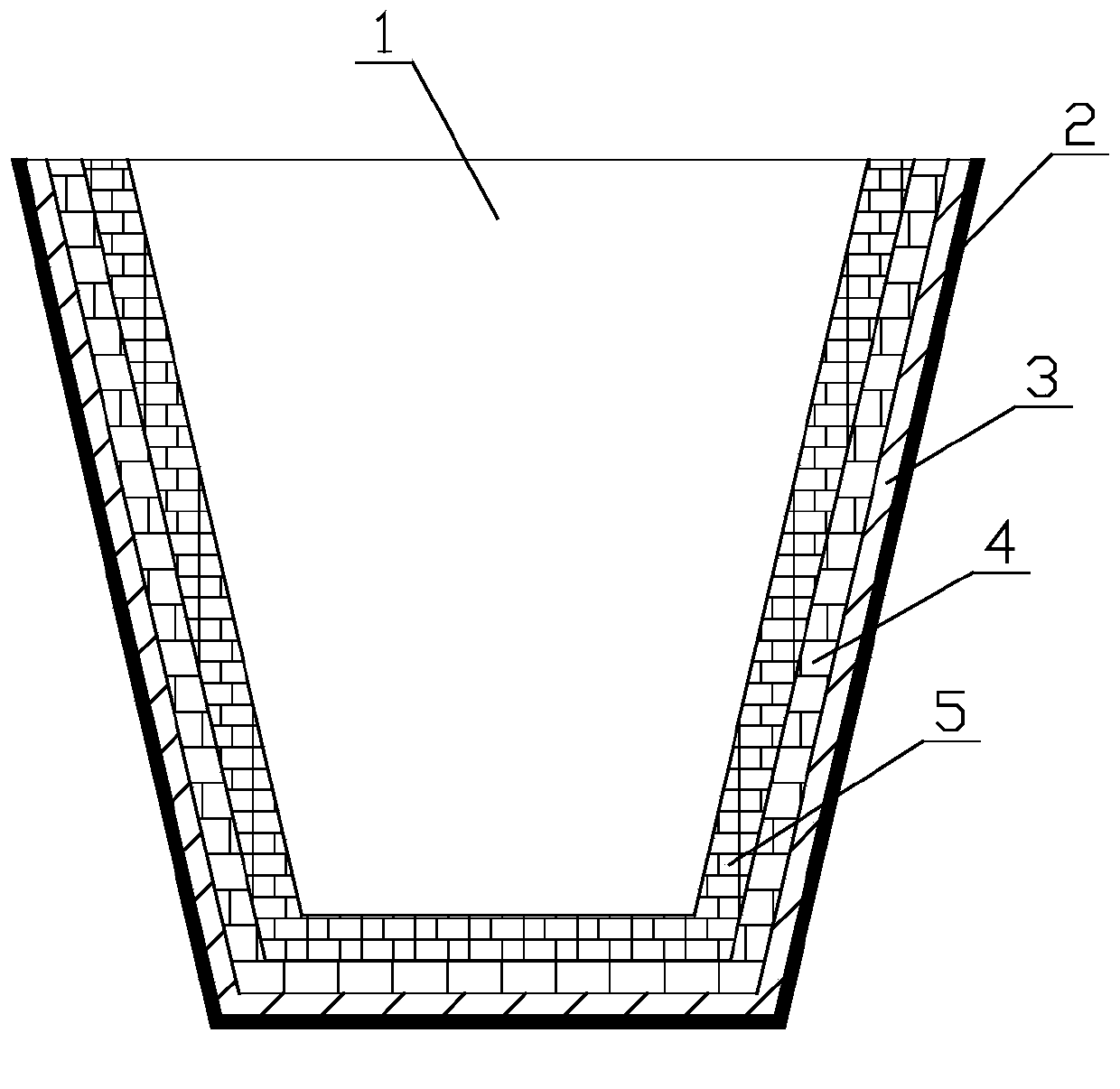

[0021] Such as figure 1 As shown, a safety ladle lining of the present invention is characterized in that it comprises a ladle body 1, an insulation layer 2, a permanent lining 3, a safety lining 4, and a working lining 5. The steel ladle body 1 is sequentially provided with heat insulation from the outside to the inside. Layer 2, permanent lining 3, safety lining 4, and working lining 5; the safety lining 4 is formed by displacing the joints of the magnesia carbon brick layer or the aluminum-magnesia carbon brick layer in the vertical direction, and the thickness of the safety lining 4 is 20-100mm; the working lining 5 is made of magnesia-carbon bricks or aluminum-magnesia-carbon bricks, and the thickness of the working lining 5 is between 100-200mm; the magnesia-carbon bricks or aluminum-magnesia-carbon bricks are both It is a fan-shaped or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com