Concave-convex surface vacuum adsorption device and manufacturing method of concave-convex surface vacuum adsorption device

A technology of vacuum adsorption and manufacturing method, which is applied in the direction of manufacturing tools, manipulators, chucks, etc., and can solve the problem of not being able to grasp cylindrical lens devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

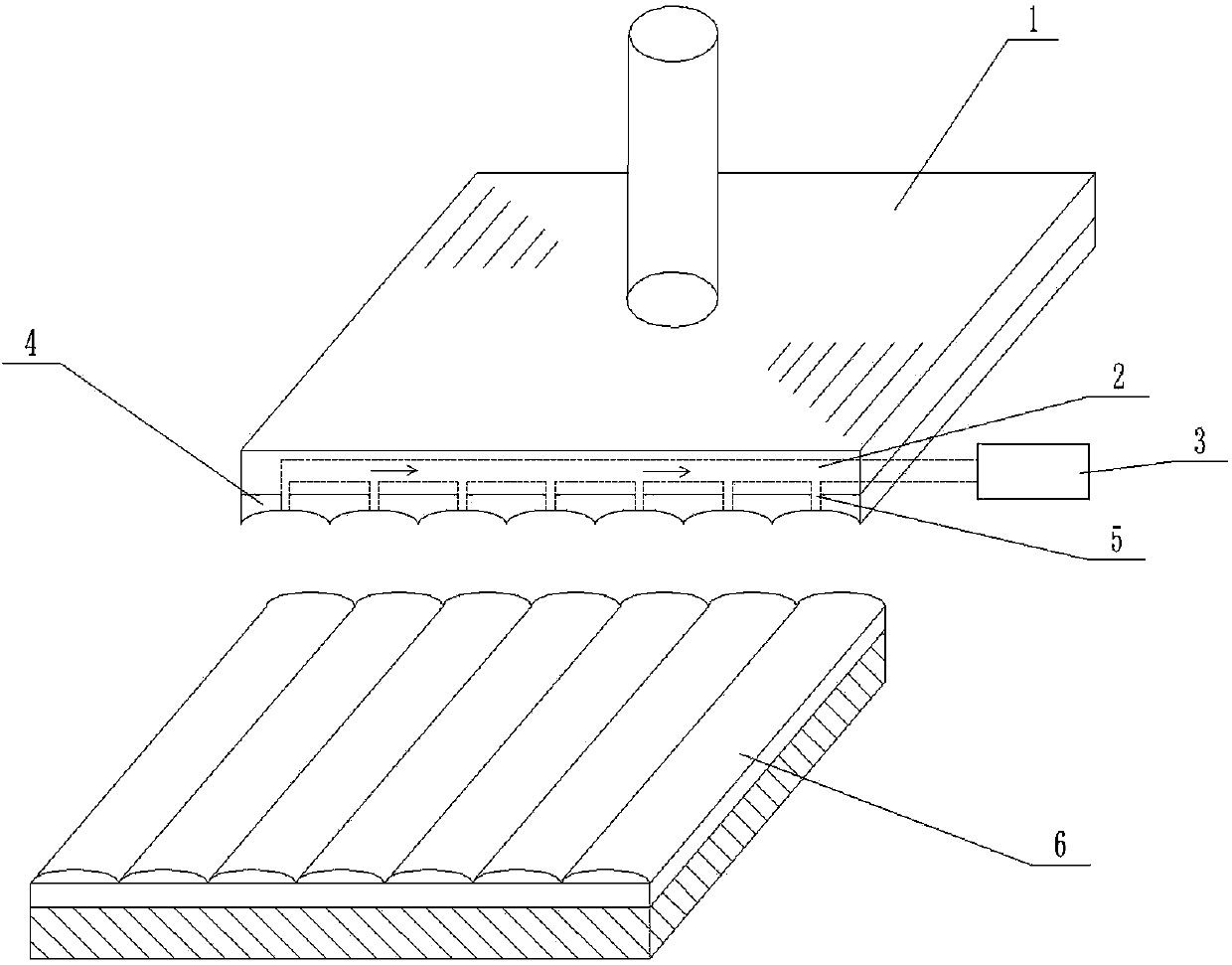

[0032] see figure 1 As shown, the concave-convex surface complementary adsorption assembly includes an adsorption membrane 4 . The suction membrane 4 is fixed on the suction surface of the vacuum suction disk 1, and the suction membrane 4 can be bonded on the suction surface of the vacuum suction disk 1 by glue. The adsorption surface of the adsorption membrane 4 is provided with a concave-convex surface complementary to the concave-convex surface on the device to be adsorbed. A plurality of air holes 5 are provided in the recesses of the concave-convex surface of the adsorption membrane 4 . In this specific embodiment, the adsorption membrane 4 is made of UV glue or silica gel. The adsorbed device is the lenticular optical device 6 .

[0033] When in use, stick the adsorption film 4 on the grating surface on the lenticular optical device 6; then turn on the vacuum generating device 3, and realize the adsorption of the lenticular optical device 6 through negative airflow. ...

Embodiment 2

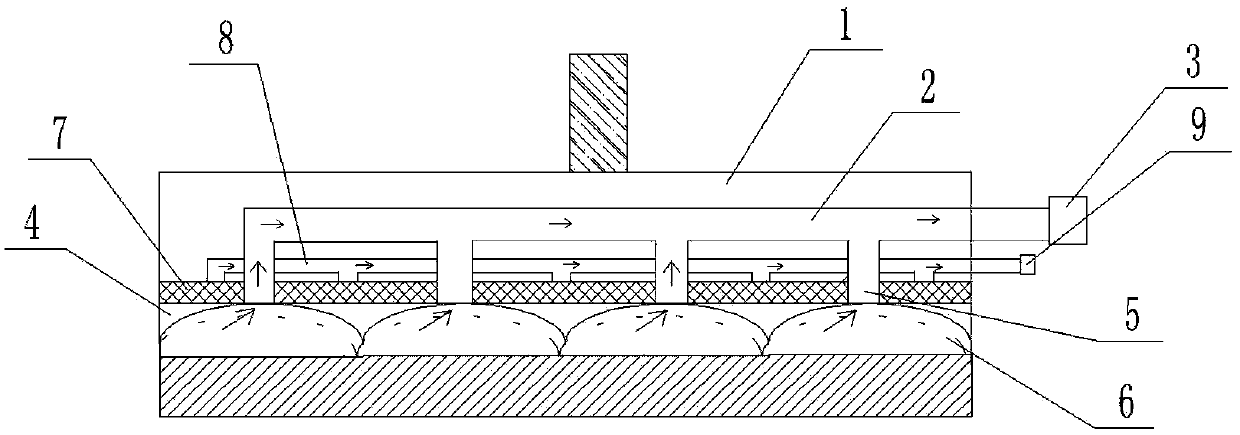

[0035] see figure 2 As shown, the concave-convex surface complementary adsorption component includes an adsorption membrane 4 and a substrate 7 . The adsorption membrane 4 is fixed on the substrate 7 , and the adsorption membrane 4 is bonded to the adsorption surface of the vacuum suction disk 1 . The substrate 7 is detachably connected to the vacuum suction plate 1, that is, the vacuum suction plate 1 is also provided with a substrate adsorption airflow channel 8, and the substrate adsorption airflow channel 8 is connected to the second vacuum On the generating device 9, the second vacuum generating device 9 and the first vacuum generating device 3 can be the same, or two vacuum generating devices controlled independently of each other, which can be used as required. This specific embodiment In the above, the first vacuum generating device and the second vacuum generating device are independent of each other; the vacuum generating device can be a vacuum generator or a small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com