Mould for producing environment-friendly flame-retardant acoustic boards

A technology of sound-absorbing panels and molds, applied in the direction of molds, etc., can solve the problems of broken and falling off sound-absorbing panels, the overall strength and bending resistance of the sound-absorbing panels are not ideal, and the performance is not comprehensive enough, and the effect of increasing the overall strength is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment the present invention will be further described:

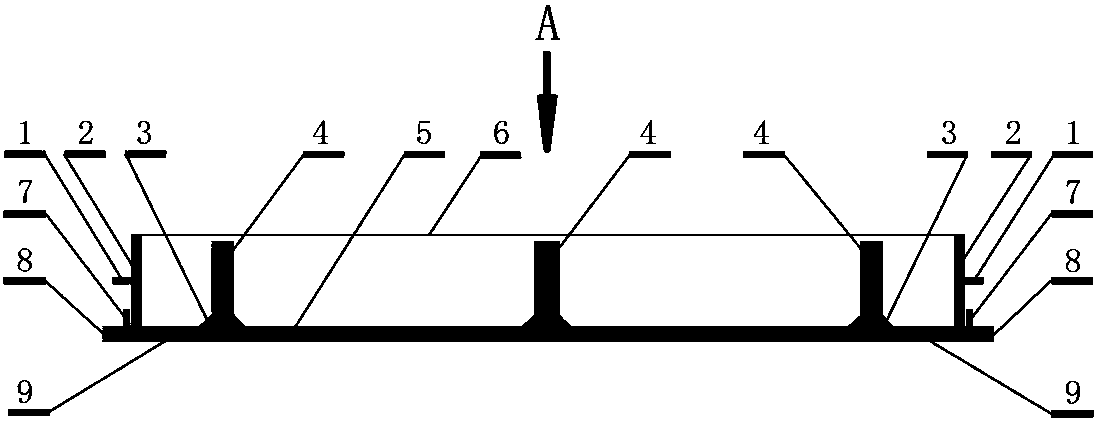

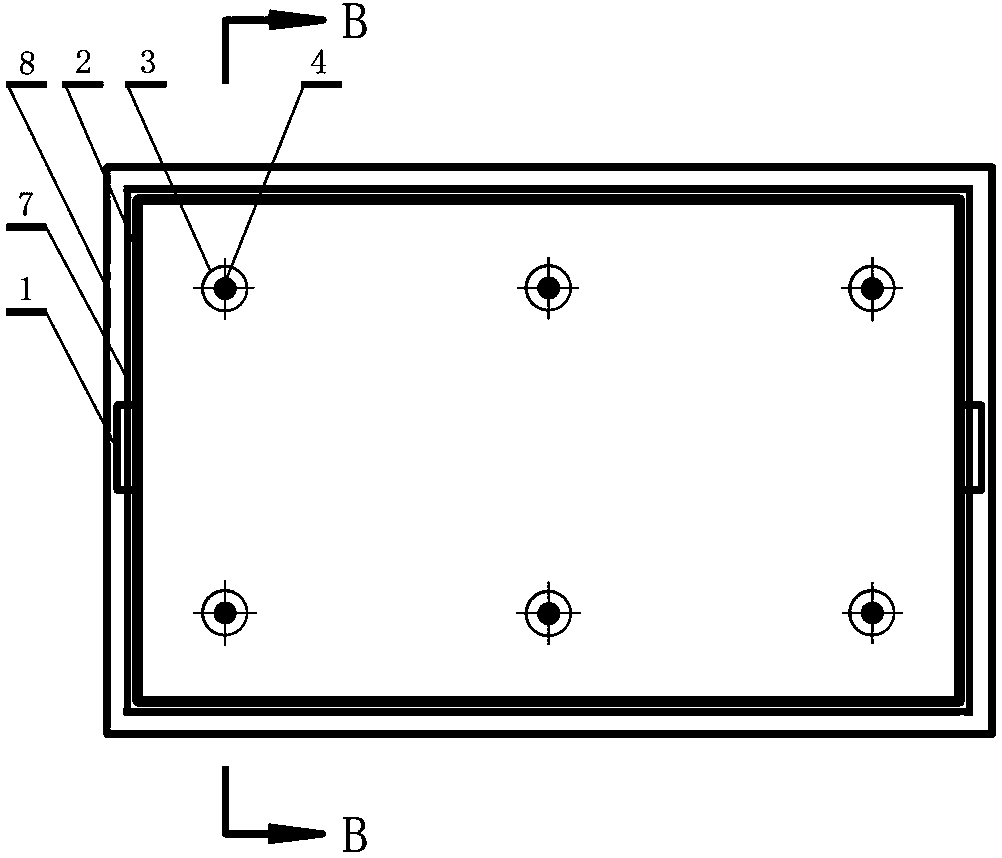

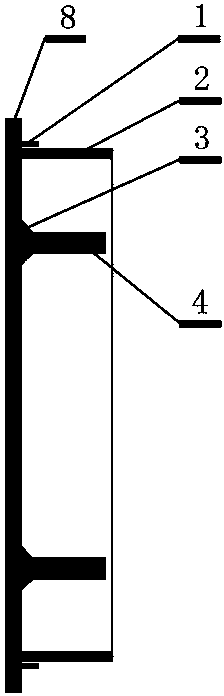

[0023] ⑴The mold used to produce environmentally friendly flame-retardant sound-absorbing panels is a rectangular mold consisting of a rectangular mold bottom plate 8, a rectangular positioning groove 7, a rectangular frame 2, 2 rectangular handles 1 and 6 columns 4; ⑵positioning Groove 7 is welded on the upper plane 5 of the mold bottom plate according to the designed position and size, the column 4 is installed on the upper plane 5 of the bottom plate according to the designed relative position size, the frame 2 is placed in the positioning groove 7, and the two handles 1 are respectively installed on the frame 2 In the middle of the outer sides of the left and right sides, the lower plane 9 of the mold base plate is placed on the vibrating workbench 14 .

[0024] The method of using the mold for the production of environmentally friendly flame-retardant sound-absorbing panels: pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com