Storehouse cleaning machine for cement storehouses

A technology of cleaning machine and cement warehouse, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems that the size of the cleaning mechanism cannot be adjusted, it is not conducive to the normal operation of the cleaning mechanism, and the cleaning mechanism is shaking violently. Wide, simple structure, small shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

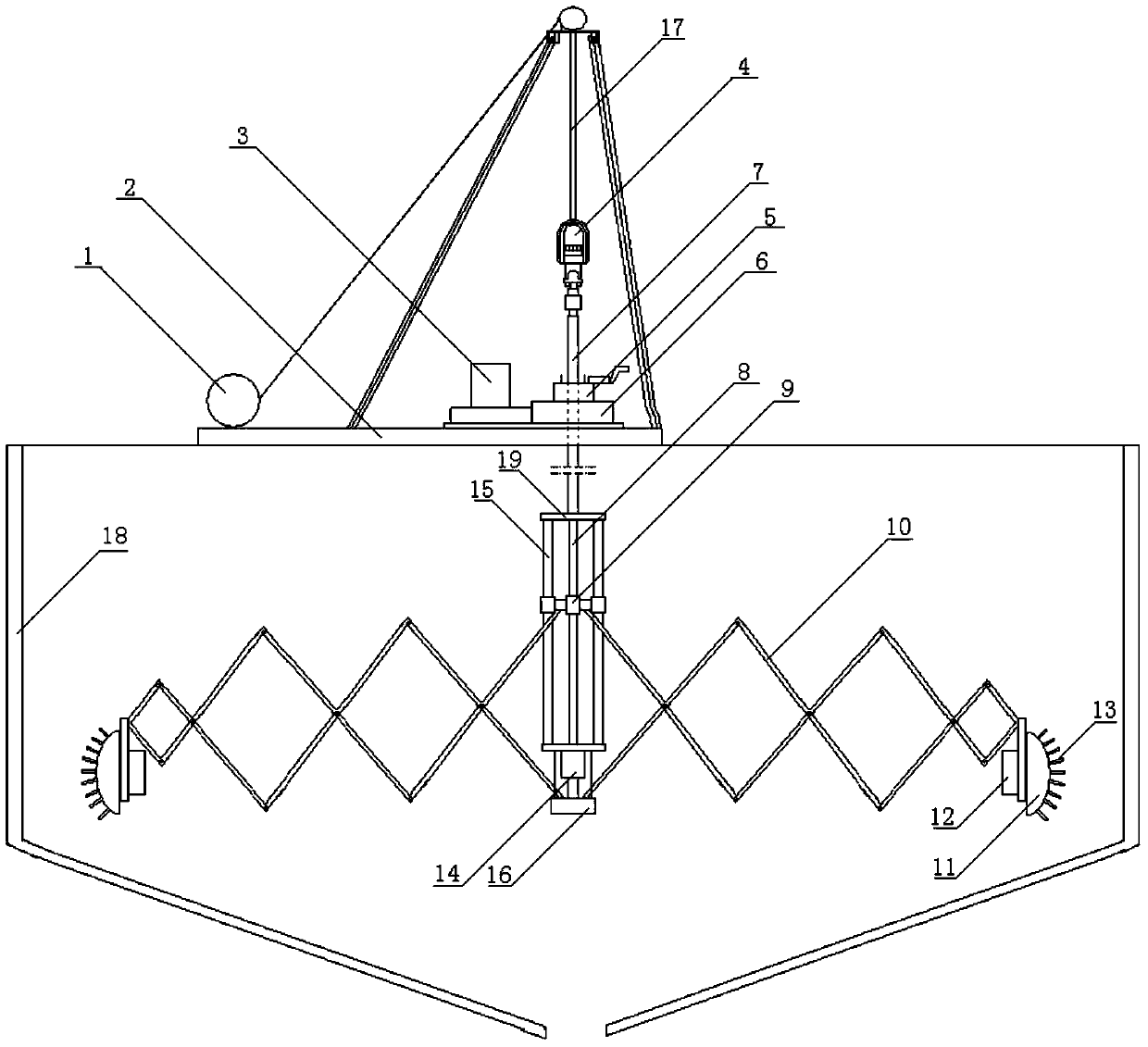

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] A cement warehouse cleaning machine, such as figure 1 As shown, it includes base 2, drill pipe 7, lifting mechanism, warehouse clearing mechanism and a rotary mechanism for controlling the rotation of the warehouse clearing mechanism. Both the lifting mechanism and the rotary mechanism are arranged on the base 2, and the lifting mechanism and the warehouse cleaning mechanism Connected by drill pipe 7. There is a movable connection between the turning mechanism and the base 2, and the turning mechanism can move on the base 2.

[0018] The hoisting mechanism includes a hoist 1, a wire rope 17, and a spreader 4. The hoist 1 is connected with the spreader 4 through the wire rope 17, and the lower end of the hanger 4 is connected with the drilling rod 7.

[0019] The slewing mechanism includes a gear motor 3, a gear reducer 6, and slips 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com