Preparation method of vinyl silicone oil

A technology of vinyl silicone oil and vinyl ring body, which is applied in the field of preparation of vinyl silicone oil, can solve the problems of poor wear resistance, low hardness of potting glue, influence on use, etc., and achieve the effect of improving wear resistance and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

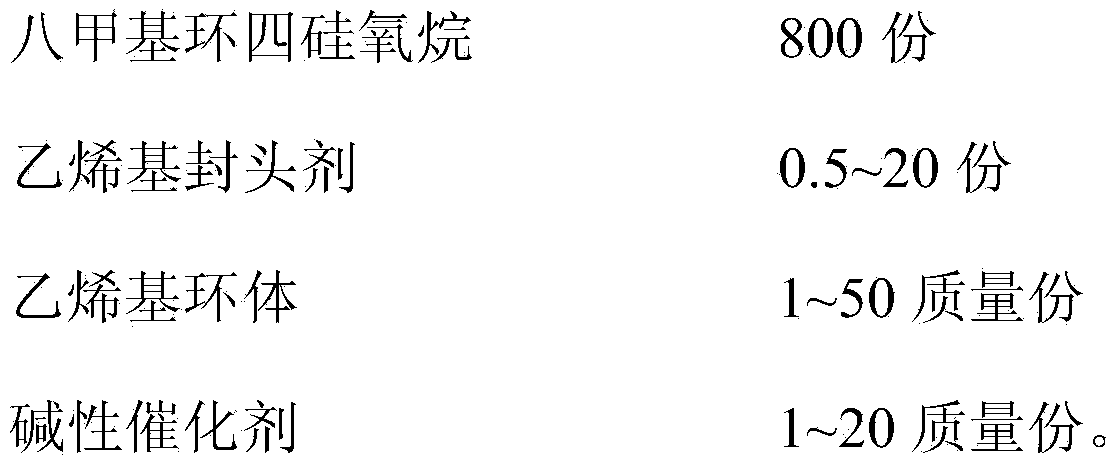

[0041] A preparation method of vinyl silicone oil, said method comprising the following raw materials in parts by mass:

[0042]

[0043] The method comprises the steps of:

[0044]Stir 800 parts of octamethylcyclotetrasiloxane in the reaction kettle, add 1 part of basic catalyst and stir in the above reaction kettle, and raise the temperature to 60°C for 1 hour at constant temperature and vacuum, add 0.5 parts of capping agent above In the reaction kettle, stir at a constant temperature of 60°C for 10 minutes, then add 1 part of vinyl ring body to the above reaction kettle, the vinyl ring body is added within 5 minutes, raise the temperature to 90°C and keep it at a constant temperature for 6 hours, then raise the temperature to 150°C Keep it for 1 hour and then raise the temperature to remove low boiling matter until no low molecular weight flows out to obtain vinyl silicone oil.

Embodiment 2

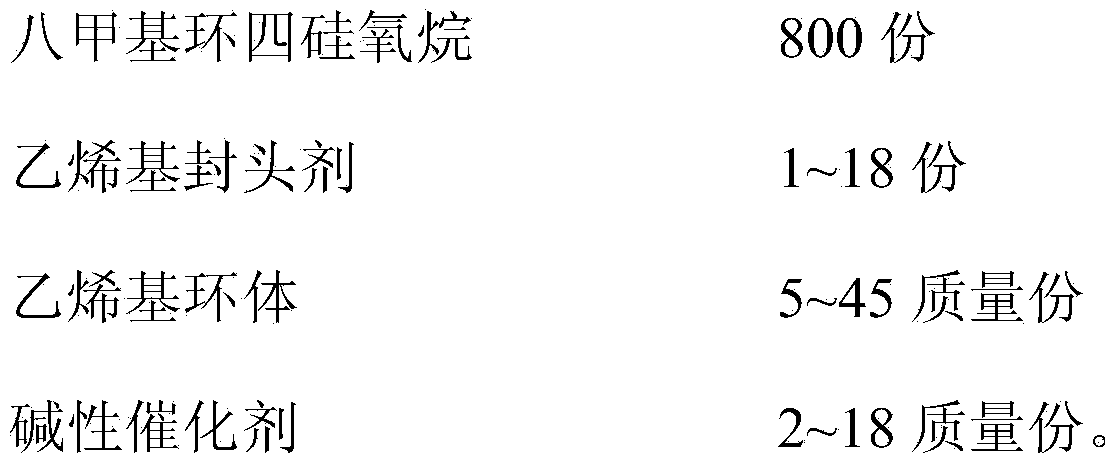

[0046] A preparation method of vinyl silicone oil, said method comprising the following raw materials in parts by mass:

[0047]

[0048] Stir 800 parts of octamethylcyclotetrasiloxane in the reaction kettle, add 20 parts of basic catalyst and stir in the above reaction kettle, and raise the temperature to 70°C for 0.5 hours at a constant temperature and vacuum, add 20 parts of vinyl capping agent In the reaction kettle, stir at a constant temperature of 70°C for 5 minutes, then add 50 parts of vinyl rings to the above reaction kettle, add the vinyl rings within 10 minutes, raise the temperature to 100°C and keep it at a constant temperature for 4 hours, then raise the temperature to Keep at 160°C for 0.5 hours, then raise the temperature to remove low boiling substances until no low molecules flow out to obtain vinyl silicone oil.

Embodiment 3

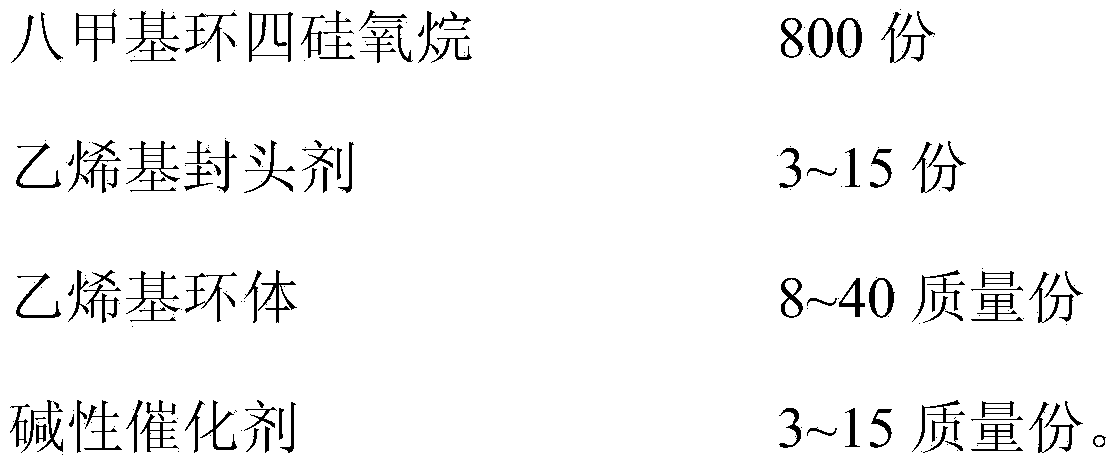

[0050] A preparation method of vinyl silicone oil, said method comprising the following raw materials in parts by mass:

[0051]

[0052] Stir 800 parts of octamethylcyclotetrasiloxane in the reaction kettle, add 10 parts of basic catalyst and stir in the above reaction kettle, and raise the temperature to 65°C for 0.7 hours at a constant temperature and vacuum, add 10 parts of vinyl capping agent In the reaction kettle, stir at a constant temperature of 65°C for 7 minutes, then add 25 parts of vinyl rings to the above reaction kettle, raise the temperature to 95°C and keep it at a constant temperature for 5 hours, then raise the temperature to 155°C and keep it for 0.8 hours, then raise the temperature to remove Low boiling matter until no low molecular weight flows out, and vinyl silicone oil is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com