Electrothermal steam drying and setting machine

A setting machine, steam technology, applied in the direction of dryer, drying, local stirring dryer, etc., can solve the problems of long cycle, large seasonal influence, high manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

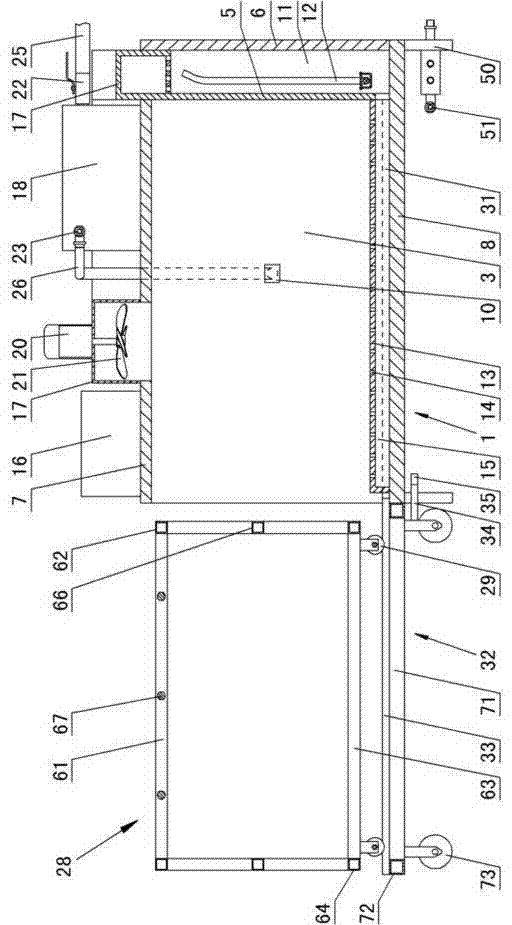

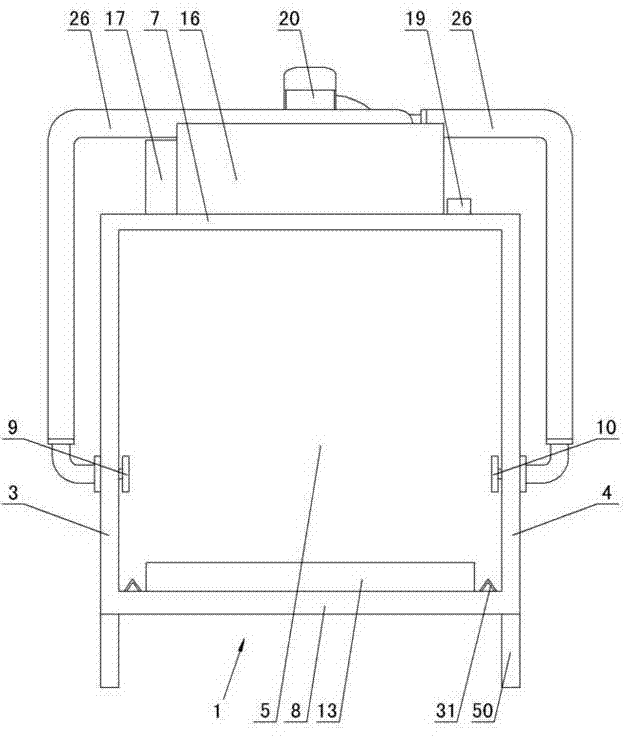

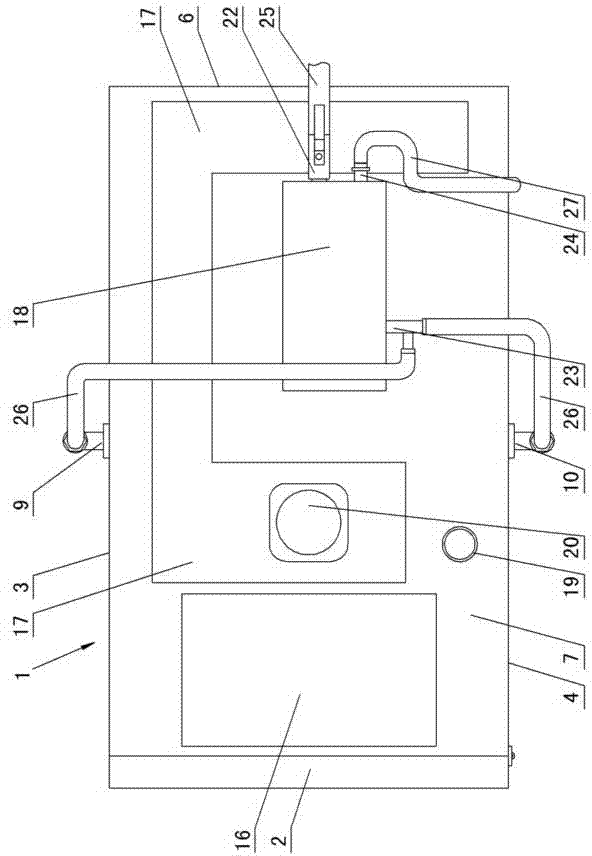

[0012] The invention relates to an electric steam drying and setting machine, such as figure 1 — Figure 5As shown, it is characterized in that: it comprises an oven 1, a movable clothes hanging frame 28 and a bottom car 32, and the oven is composed of an oven door 2, a left box panel 3, a right box panel 4, a dividing plate 5, a rear box panel 6, a cabinet The top plate 7, the box bottom plate 8 and the foot 50 are composed of a drain joint 51 installed on the foot, the left air nozzle 9 is installed on the left box plate 3, the right air nozzle 10 is installed on the right box plate 4, the partition 5 and the rear box There is an installation room 11 between the boards 6, an electric heating pipe 12 is installed in the installation room, and a suction plate 13 is arranged on the bottom plate 8 of the box. The suction plate has a suction hole 14, and the middle part of the suction plate is hollow 15. One end is communicated with the bottom of the installation chamber 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com