A single row double eccentric wheel shaker

A technology of double eccentric wheel and vibrating machine, which is applied in the paper machine, wet end of paper machine, textile and paper making, etc., can solve the problems of low vibration frequency, poor uniform pulp, large foundation force, etc., and achieves low cost , The effect of improving pulp uniformity and reducing reaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

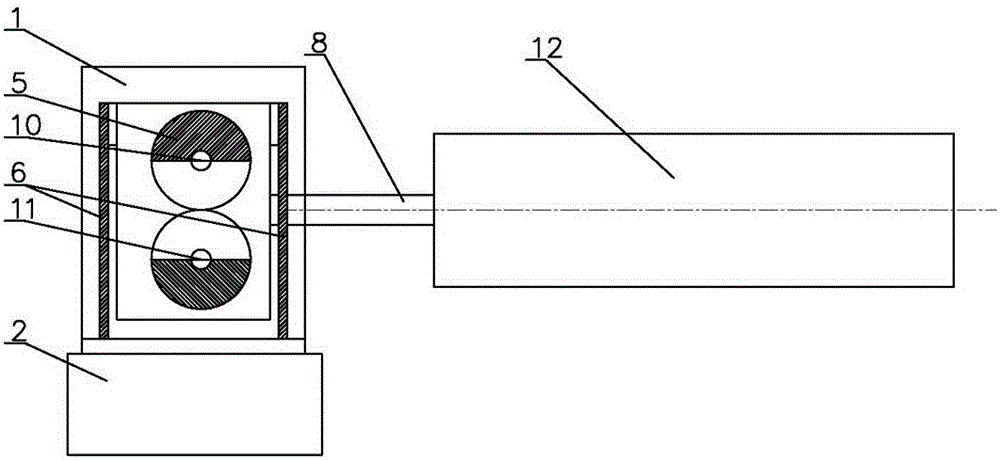

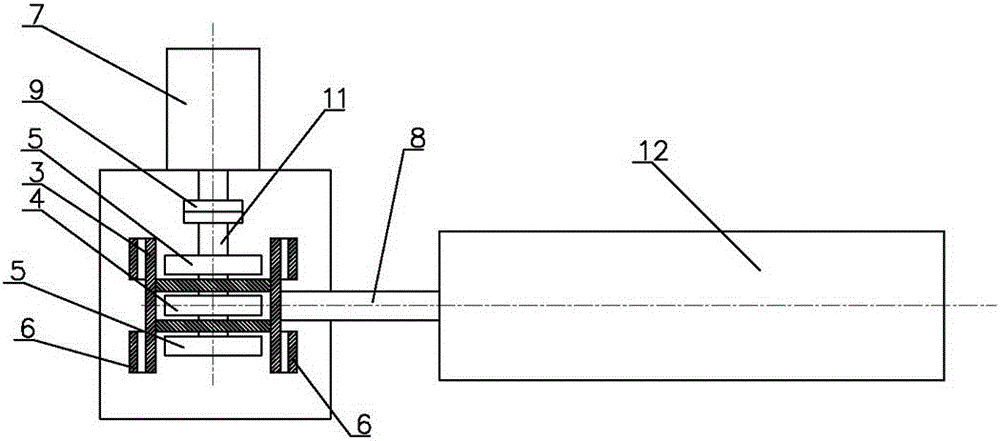

[0015] Such as figure 1 , figure 2 As shown, the present embodiment is a single row double eccentric wheel vibrating machine with a support 2 fixed to the ground, and a vibrating frame 1 fixed on the top of the support. The vibrating machine also includes three parts: a driving part, a vibrating part and an output part. The output section is connected to the wire section 12 of the paper machine.

[0016] In this example, the driving component is the motor 7, which provides driving force for the vibrating component. The vibrating part is composed of spring plate 6, coupling 9, core frame 3, driving shaft 11, driven shaft 10, gear 4 and eccentric block group 5. There are two spring plates 6 (or four at the four corners, or Three pieces on each side) are vertically fixed on the bottom of the shaking frame 1, and the core frame 3 that can swing freely is suspended between the spring plate tops. The shape of core frame 3 is as figure 2 As shown, similar to H shape, there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com