Annular preventer with internally-arranged circulating water cooling system

An annular blowout preventer and circulating water cooling technology, applied in wellbore/well components, earthwork drilling, sealing/packaging, etc., can solve the problems of annular blowout preventer failure, slow piston action, and easy aging of rubber cores. Achieve the effect of eliminating hidden dangers of accidents, sensitive action, and reducing the temperature of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

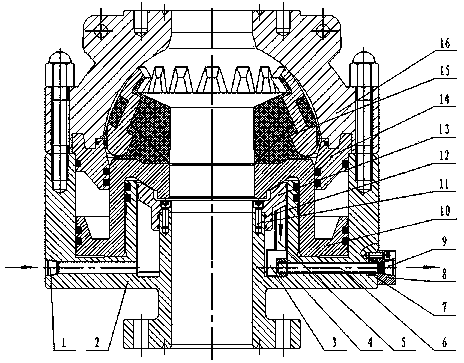

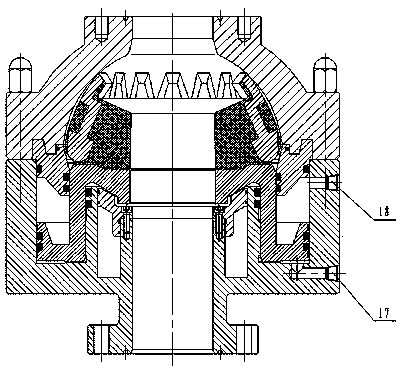

[0012] The present invention demonstrates its implementation through its working principle. In the process of gas production, the annular blowout preventer is normally open, the gas production pipeline passes through the vertical passage of the blowout preventer body 2, and the annular blowout preventer has a built-in piston 10 and a rubber core 15. When the blowout preventer needs to be closed , The oil inlet 17 enters the oil, the oil return 18 returns the oil, the piston 10 moves up under the action of the hydraulic oil, pushing the rubber core 15, and the rubber core 15 can only perform centripetal contraction deformation under the obstruction of the top cover 16, thereby sealing and preventing Vertical channel in the sprayer body 2.

[0013] When the gas with a high formation temperature of 300℃ passes through the annular blowout preventer, it will transfer a large amount of heat to the blowout preventer body 2, making the blowout preventer body 2 in a high temperature state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com