Piston cylinder device for internal combustion engine and large-scale engine

A technology for internal combustion engines and piston cylinders, which is applied in the direction of engine lubrication, engine components, machines/engines, etc., and can solve problems such as losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

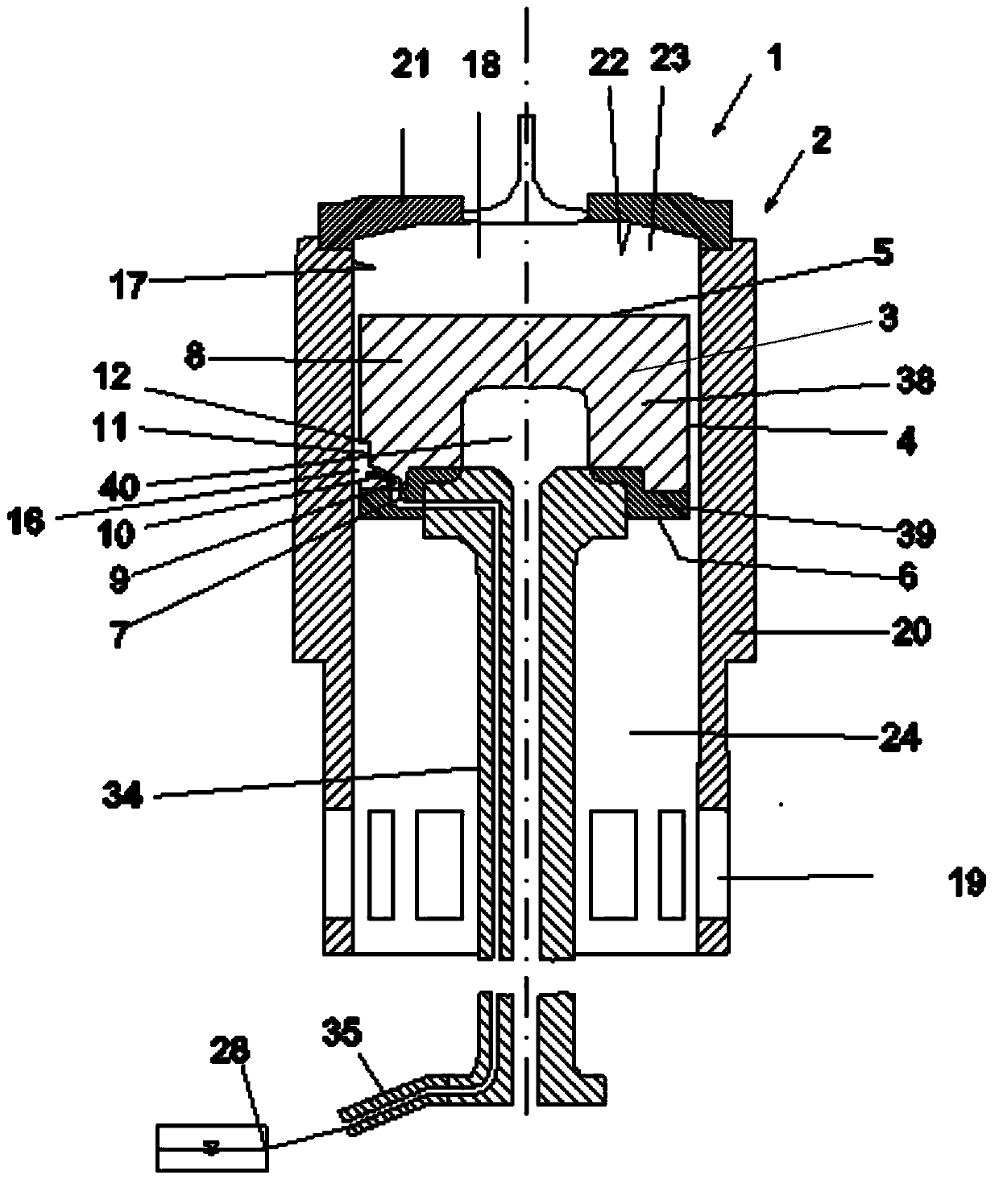

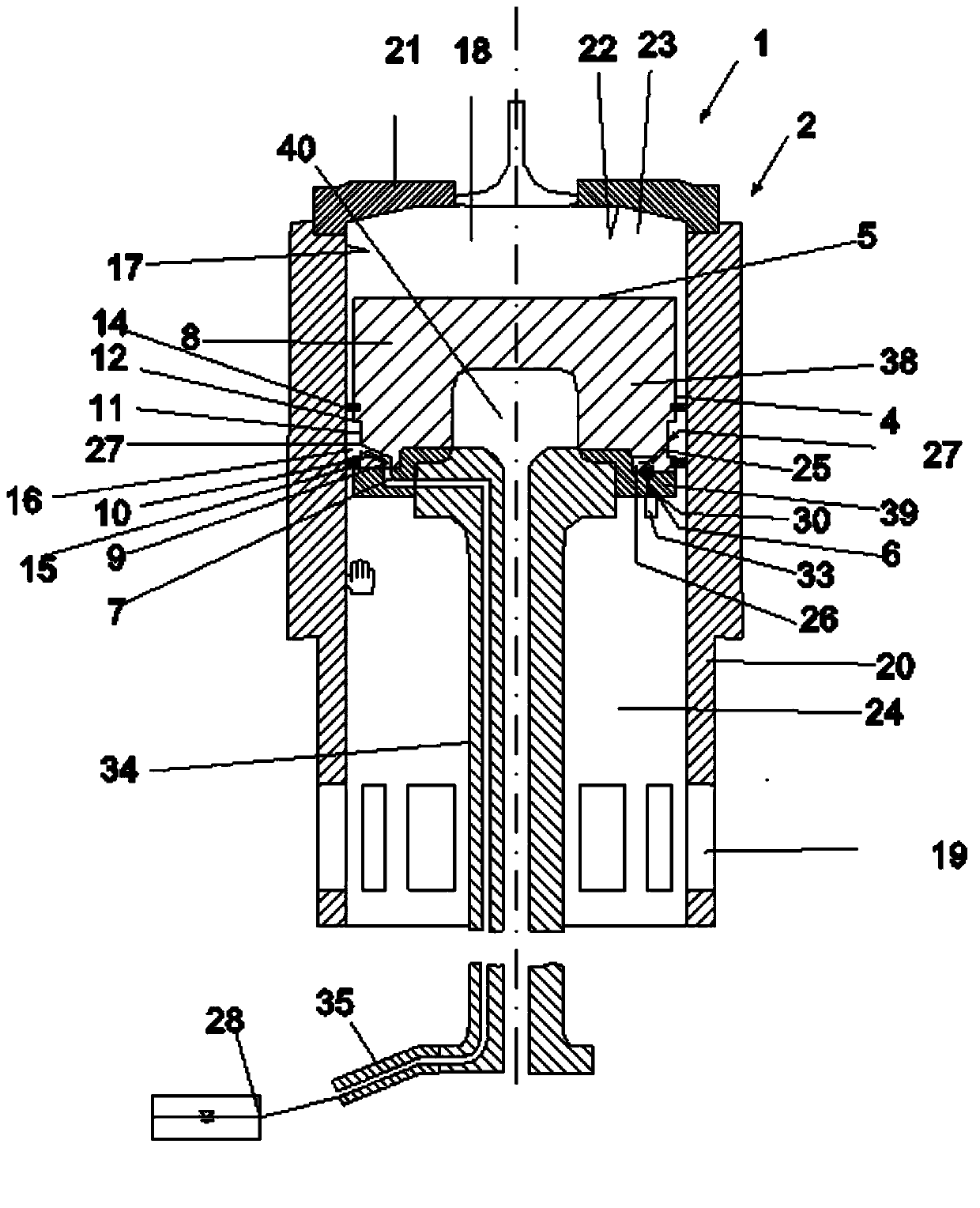

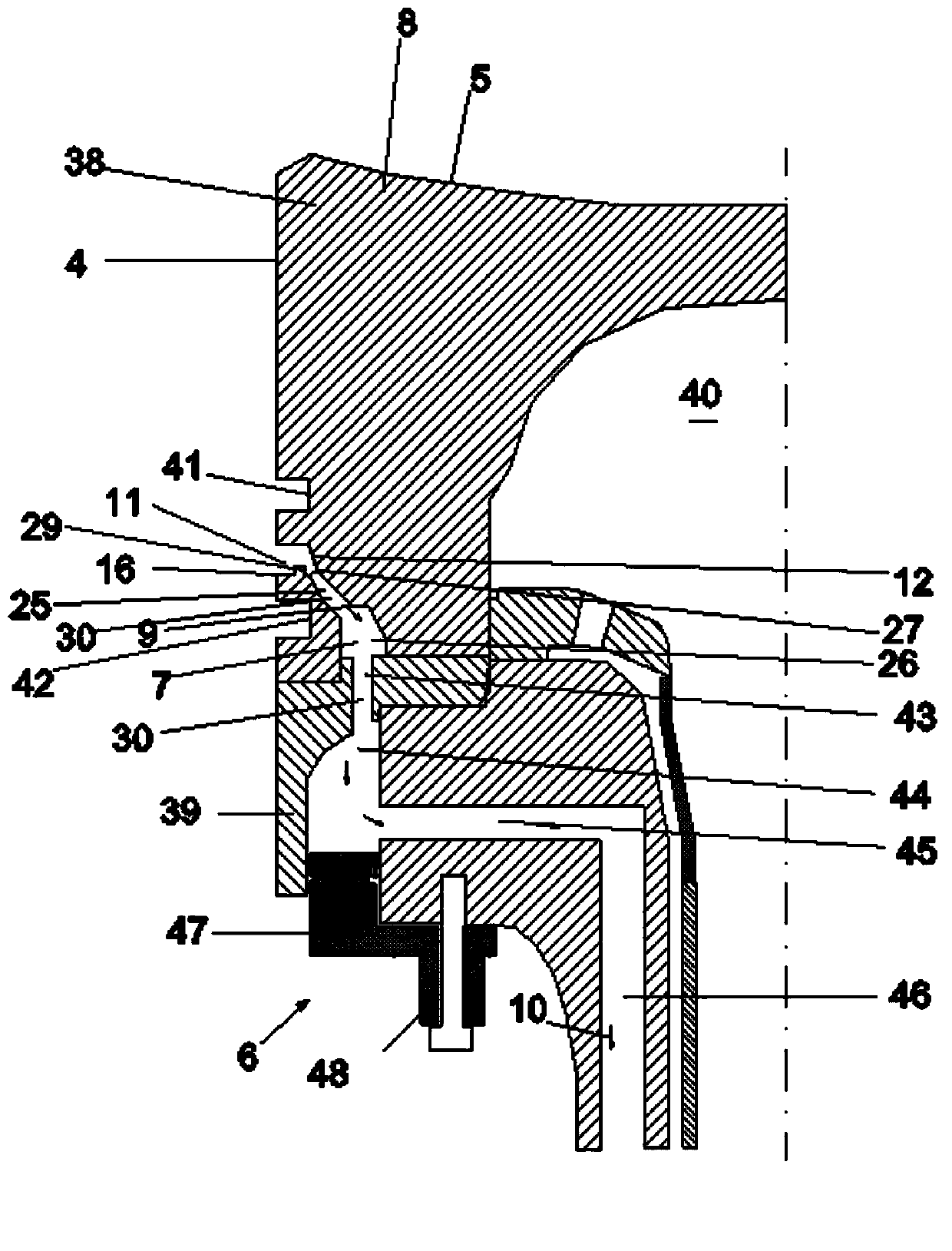

[0054] according to figure 1 The illustrated piston-cylinder arrangement 2 of a large engine 1 or compressor comprises a cylinder 20 and a piston 3 . The cylinder block 20 has a cylinder liner 17 delimiting a cylinder interior space 18 . The piston 3 has a piston top 5 and a piston bottom 6 . The piston jacket surface 4 , the piston upper side 5 and the piston underside 6 delimit a piston body 8 . The piston body 8 can comprise several parts, for example it can comprise a piston head 38 and a piston skirt 39 . The piston body 8 can be at least partially provided with a hollow space 40 through which coolant can be introduced into the piston body 8 . The piston 3 comprises a lubricant collecting device 7 arranged in the piston inner space. The lubricant collecting means 7 comprises a recess 11 at the piston jacket surface 4 and a channel 9 for receiving a lubricant-containing gas 10 . The channel 9 adjoins the recess 11 in the piston body 8 , so that a lubricant-containing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap