Low-temperature vacuum drying box

A low-temperature vacuum drying and cabinet technology, which is applied in drying chambers/containers, drying solid materials, local agitation dryers, etc., can solve problems such as difficult drying, and achieve the effect of smooth temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

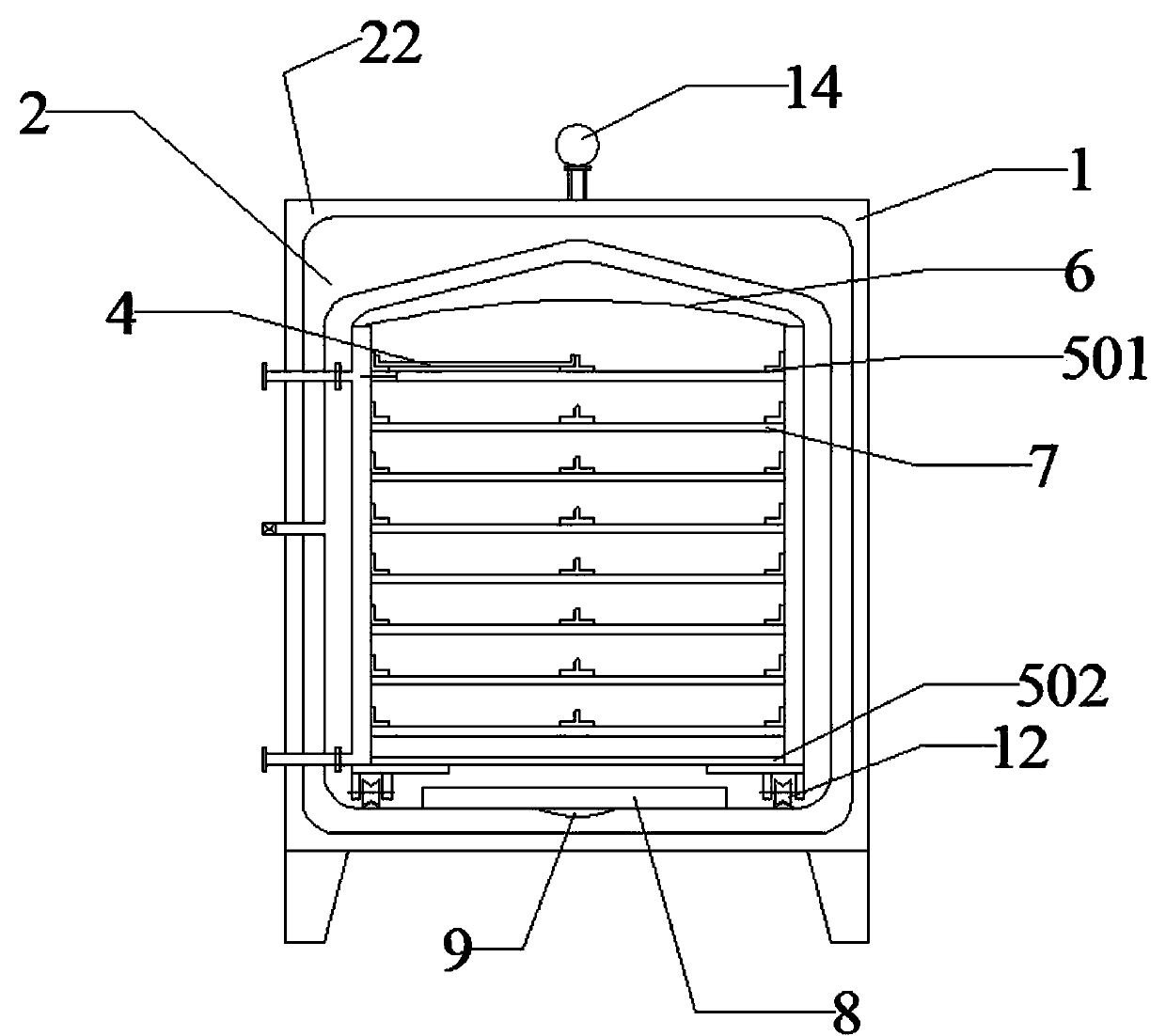

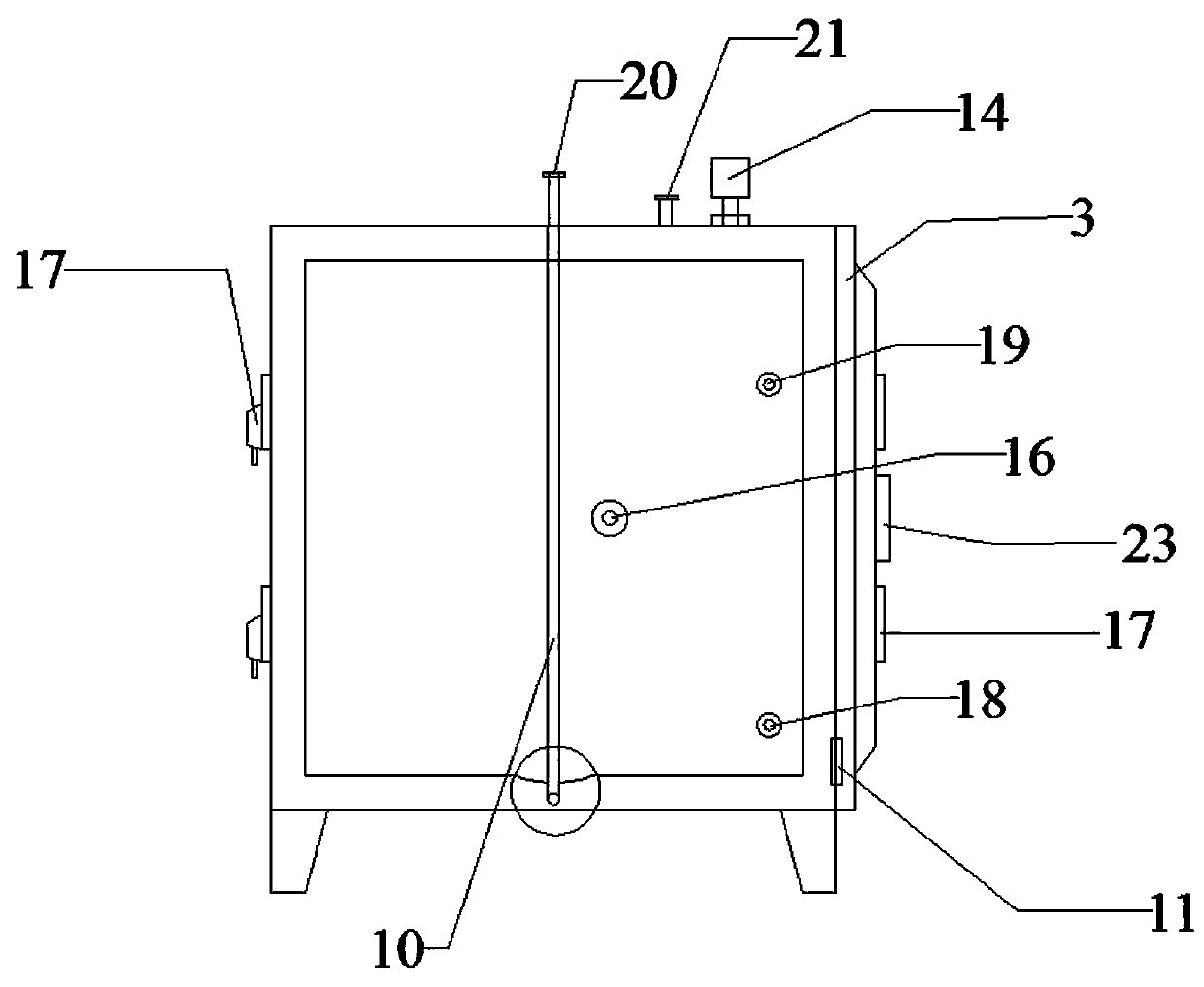

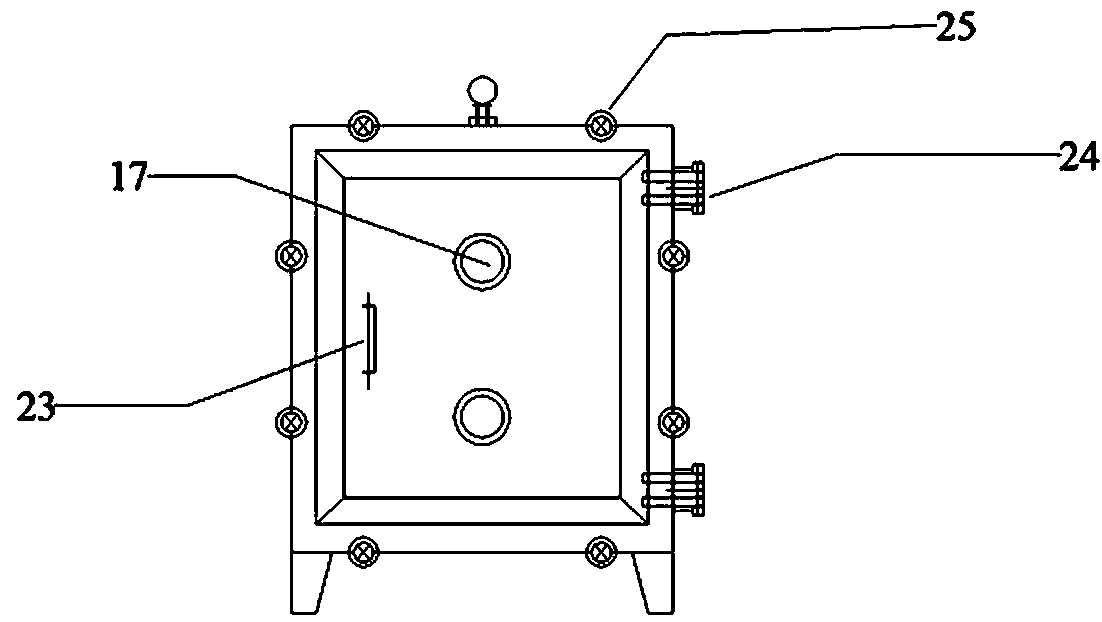

[0027] A low-temperature vacuum drying oven includes a box body 1, a working chamber 2 arranged inside the box and a box door 3 arranged outside the box, and the working room 2 includes: a baking tray 4 for placing the The first type of drying rack 501 of the baking tray 4, the baffle plate 6 arranged under the top of the working room 2, the heat dissipation coil 7 arranged under the first type of drying rack 501, and the bottom of the working room 2 The water retaining strip 8 near the box door 3, the sewage outlet 9 located in the middle of the bottom of the working room 2, and the condensed water vacuum pipe 10 connected to the sewage outlet 9; the top and bottom of the working room 2 are semi-elliptical, Its top corners are arc angles; it also includes a second type of drying rack 502 located below the first type of drying rack 501; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com