A sapphire furnace intermittent temperature measuring device

A temperature measuring device, sapphire technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve problems such as practical experience and demanding technical requirements, and achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

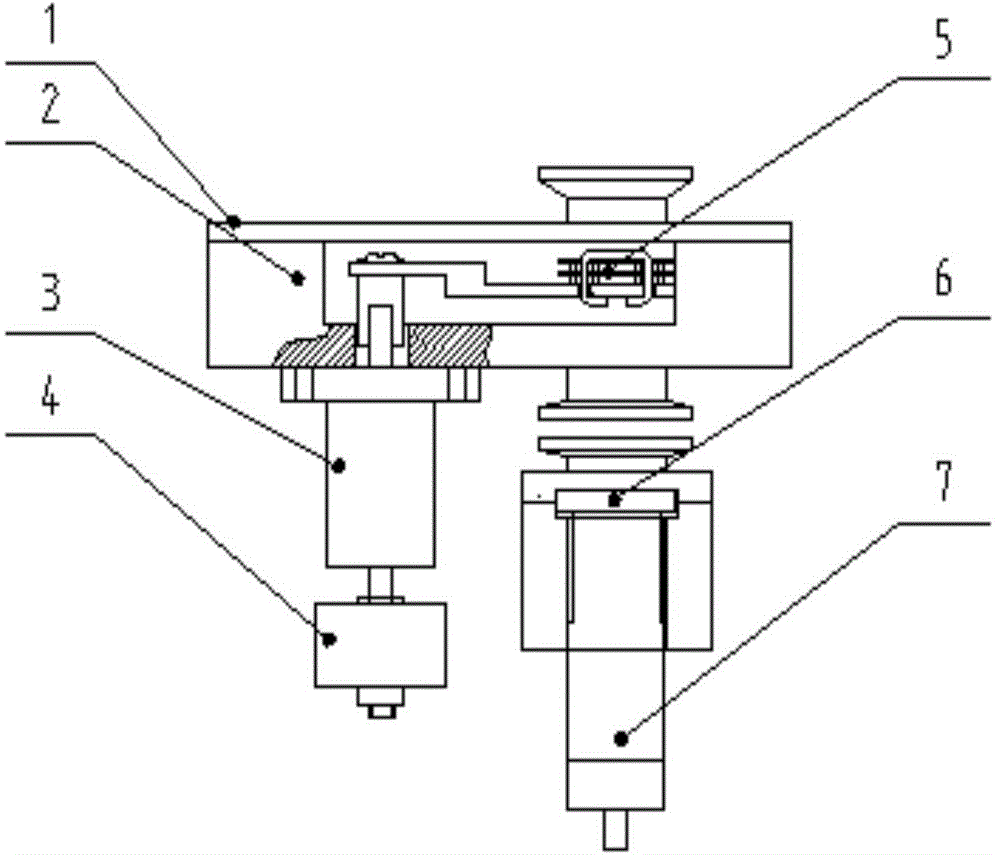

[0018] figure 1 The intermittent temperature measuring device of the sapphire furnace includes an infrared thermometer 7, an upper plate 1, a lower plate 2, a shading plate 5, a rotating shaft, a rotating sealing structure 3, a swing cylinder 4 and an observation glass 6, wherein the infrared thermometer is used 7 is used to measure the temperature, the measured value is accurate, the response is sensitive, and the operator can detect the temperature change inside the furnace body in time, so as to make a correct judgment.

[0019] The upper plate 1 and the lower plate 2 are connected to form an airtight cavity, and the shading plate 5 is installed in layers in the airtight cavity in a pagoda shape, which has a better effect on heat insulation. The swing cylinder 4 is connected with a compressed air machine, and the compressed air machine is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com