Electrified measuring and sampling tool for coating thickness of anti-pollution flashover coating for electrical equipment

A technology of anti-pollution flashover coatings and power equipment, which is applied in the direction of measuring devices, instruments, etc., can solve problems such as the impossibility of sampling the thickness of the coating, the short schedule of power outage work, and the hidden dangers of equipment safety operation, so as to achieve good sampling and detection effects, Guarantee safe operation and powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

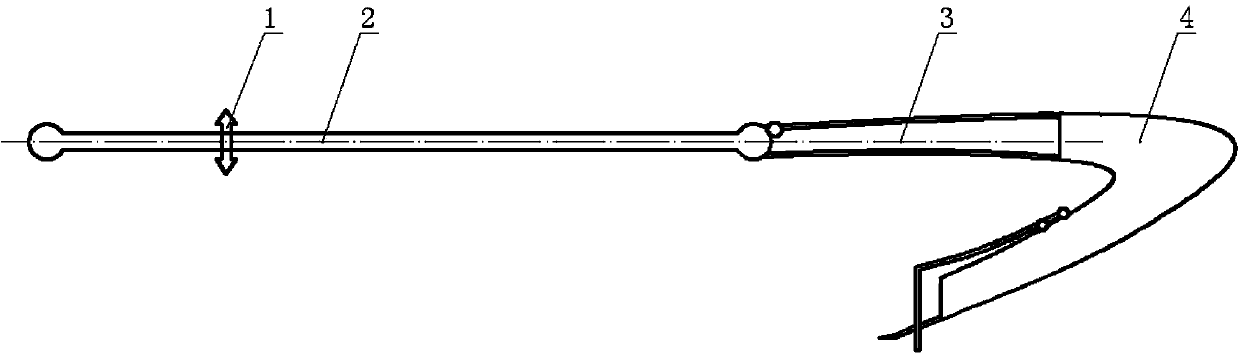

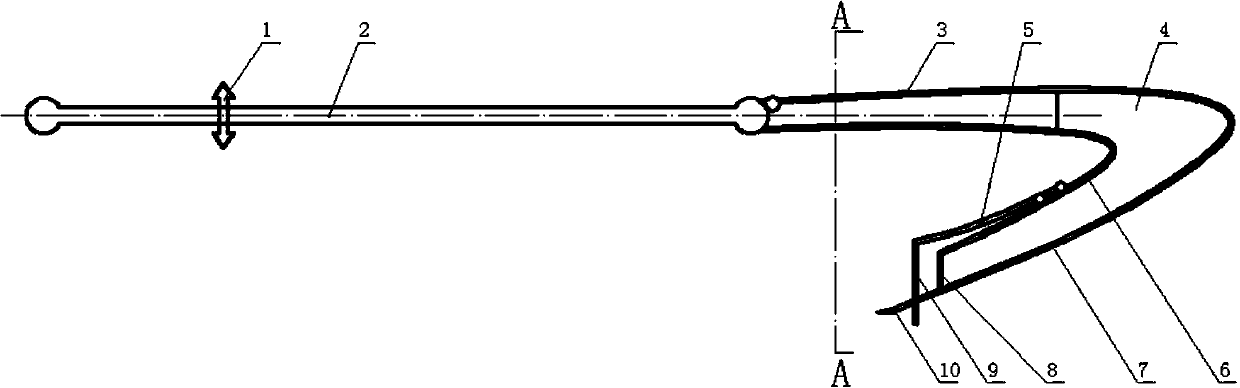

[0023] A live measurement sampling tool for anti-pollution flashover coating application thickness of electric equipment, including an insulating rod 2, a safety limit mark 1 and a sampling device 3, and a safety limit mark is fixed on the insulating rod on the hand-held side to remind the operator The safe distance of live operation ensures safety; one end of the insulating rod is equipped with a sampling device.

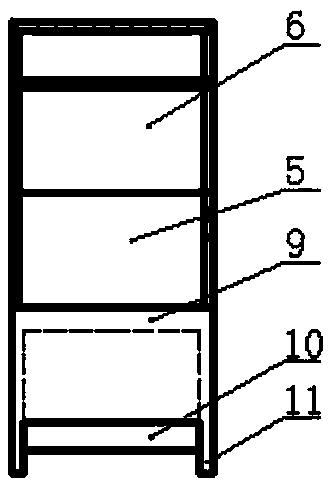

[0024] The specific structure of the sampling device is as attached figure 1 to attach image 3 As shown, the sampling device includes a sample collection bin 4, a bin door 8, an elastic arm 5, an intercepting plate 9, a scraper 10 and a support leg 11, and the sample collection bin is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com