Radiator for thyristor short-time junction temperature protection and protection time acquisition method thereof

A thyristor and radiator technology, which is applied to the radiator for short-term junction temperature protection of thyristor and the acquisition of its protection time, can solve the problems of limited application of phase change materials, low thermal conductivity, large volume, etc., and can restrain the rapid growth of junction temperature. , The effect of high thermal conductivity and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will be further described in conjunction with the accompanying drawings and specific examples, so that those skilled in the art can better understand the advantages and characteristics of the present invention, so as to implement the present invention, but the examples given are not intended to limit the present invention.

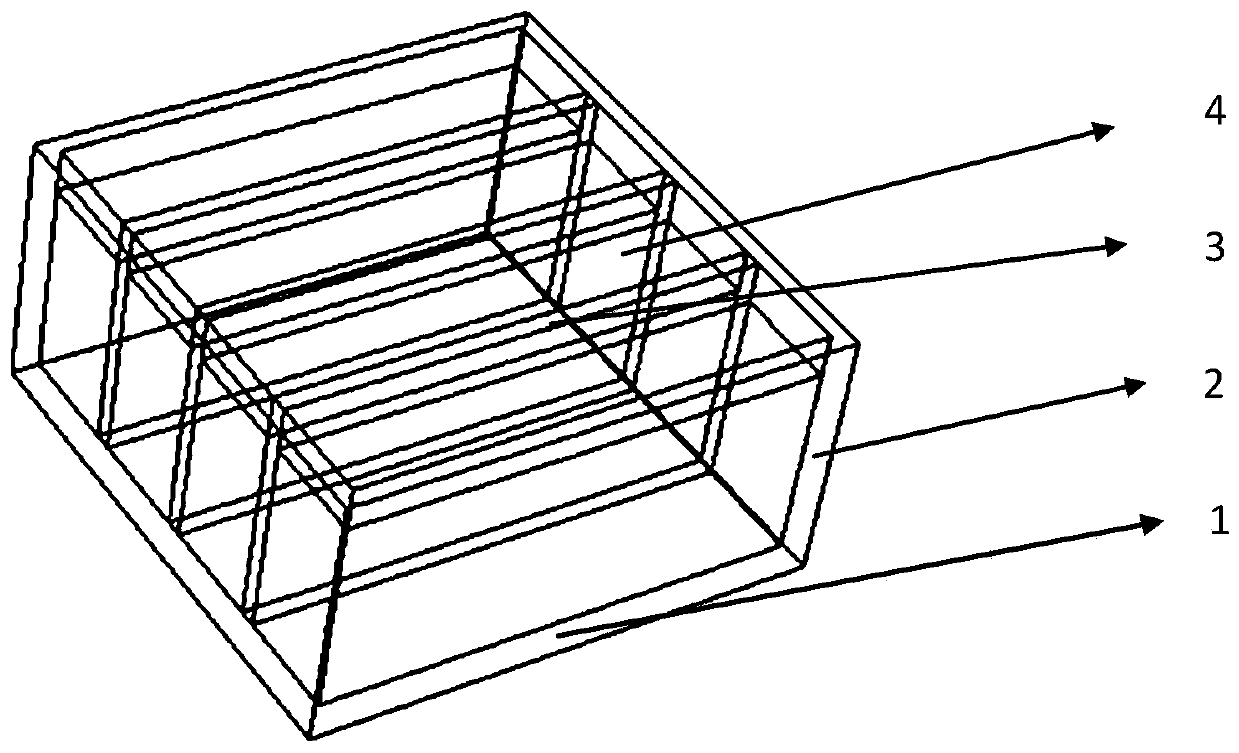

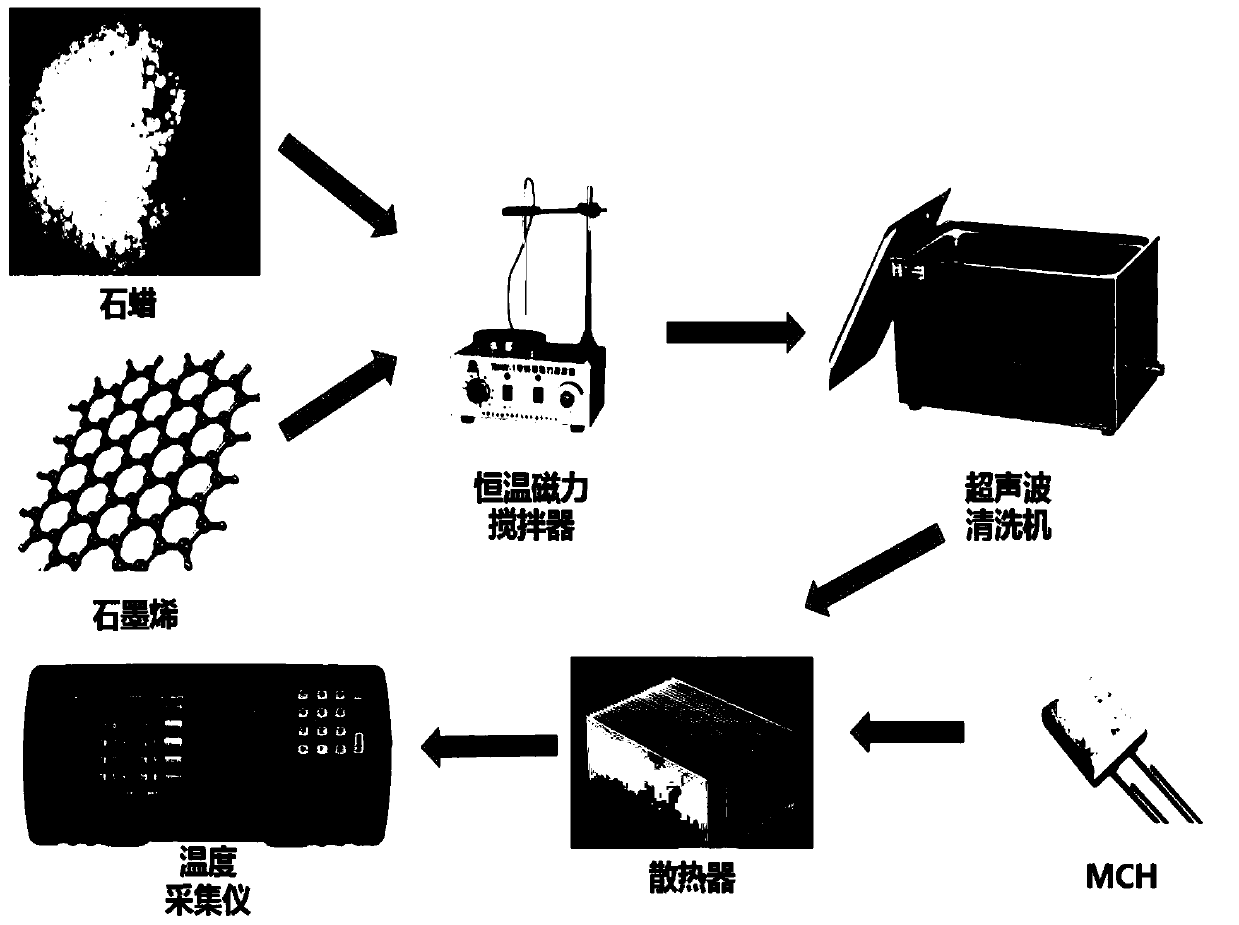

[0039] In this embodiment, it is necessary to establish a reliable heat conduction channel with low thermal resistance in the phase change material matrix, reduce the temperature difference in the phase change material, and increase the thermal conductivity of the matrix. The method for increasing the thermal conductivity of the phase-change material in this embodiment is as follows: first, add metal heat-conducting fins inside the phase-change radiator, such as inserting fins, adding foam metal, and adopting a honeycomb structure. With the increase of the internal metal structure , the internal heat conduction channel of the phase chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com