Flying ash sampling device of electric dust remover

A sampling device and electrostatic precipitator technology, applied in sampling devices and other directions, can solve the problems of inaccurate sampling, difficulty and poor representation, and achieve the effects of good representation, high data accuracy, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

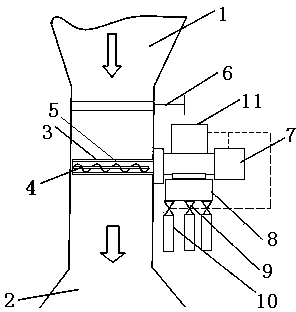

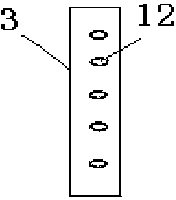

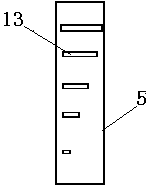

[0021] Refer to attached figure 1 , the present embodiment mainly opens a hole on the pipeline between the electrostatic precipitator ash bin 1 and the bin pump 2, inserts the sampling cylinder 3 from the hole, sets a through hole 12 on the wall of the sampling cylinder 3, and axially arranges an auger in the sampling cylinder 3 4. The auger 4 is connected to the shaft of the motor 7 outside the pipeline. A fly ash distributor 8 is installed between the motor 7 and the pipeline. The fly ash distributor 8 is respectively connected to the ash storage tank 10 through 3 pneumatic ball valves 9. The distributor 8 is set on the outside of the pipeline On the auger 4, the motor 7 and the pneumatic ball valve 9 are controlled by the controller 11. The inner cylinder 5 is arranged in the sampling cylinder 3, the hole 13 is arranged on the inner cylinder 5, and the inner cylinder 5 is threadedly connected with the sampling cylinder end on the outside of the pipeline. , the hole 13 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com