On-line rectification product concentration detecting device

A technology of product concentration and detection device, applied in the direction of measurement device, specific gravity measurement, instrument, etc., can solve the problem of inconvenient online detection of rectified products, and achieve the effect of saving experimental cost and facilitating experimental operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In conjunction with accompanying drawing, provide embodiment of the present invention as follows, but the present invention is not limited to following embodiment:

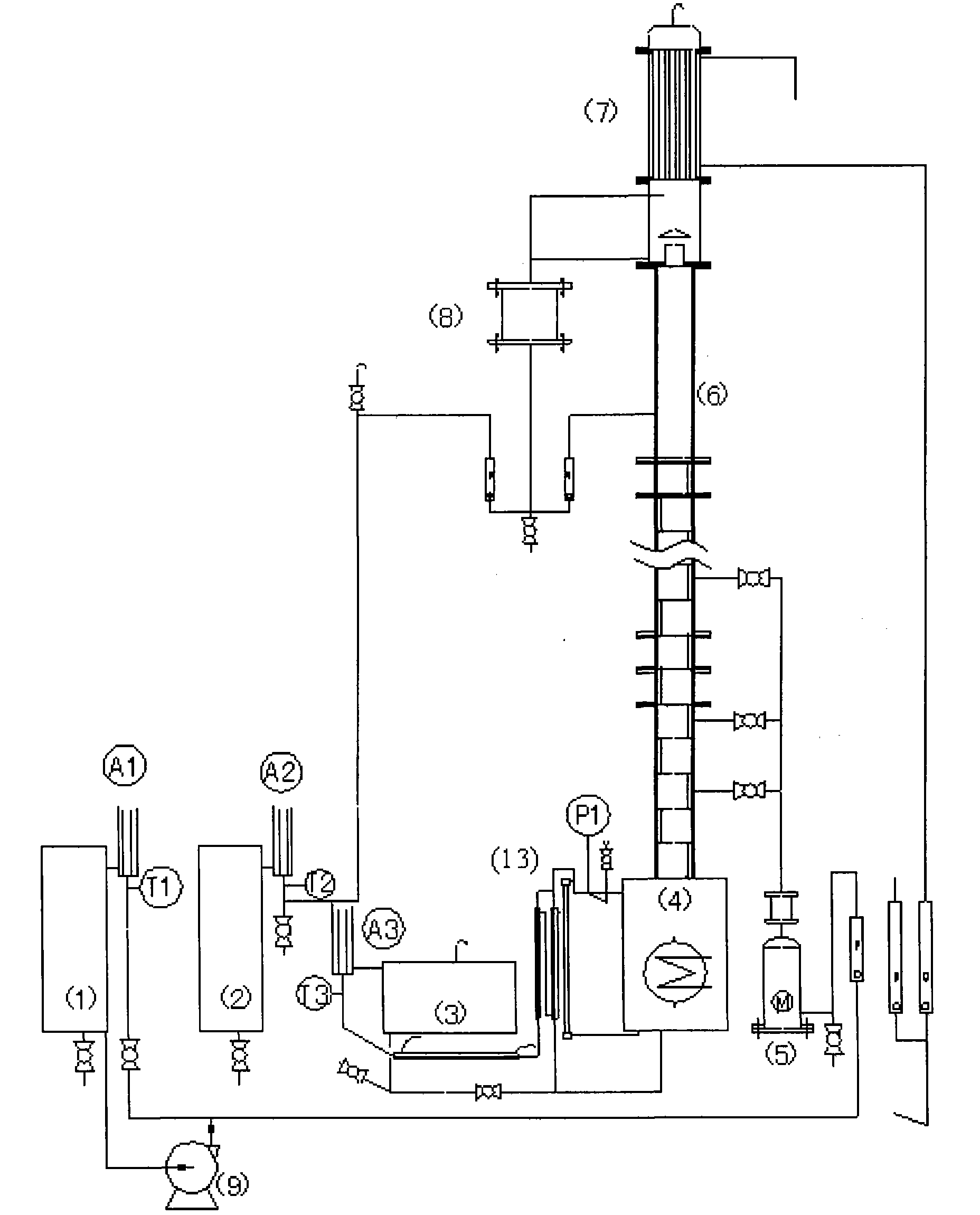

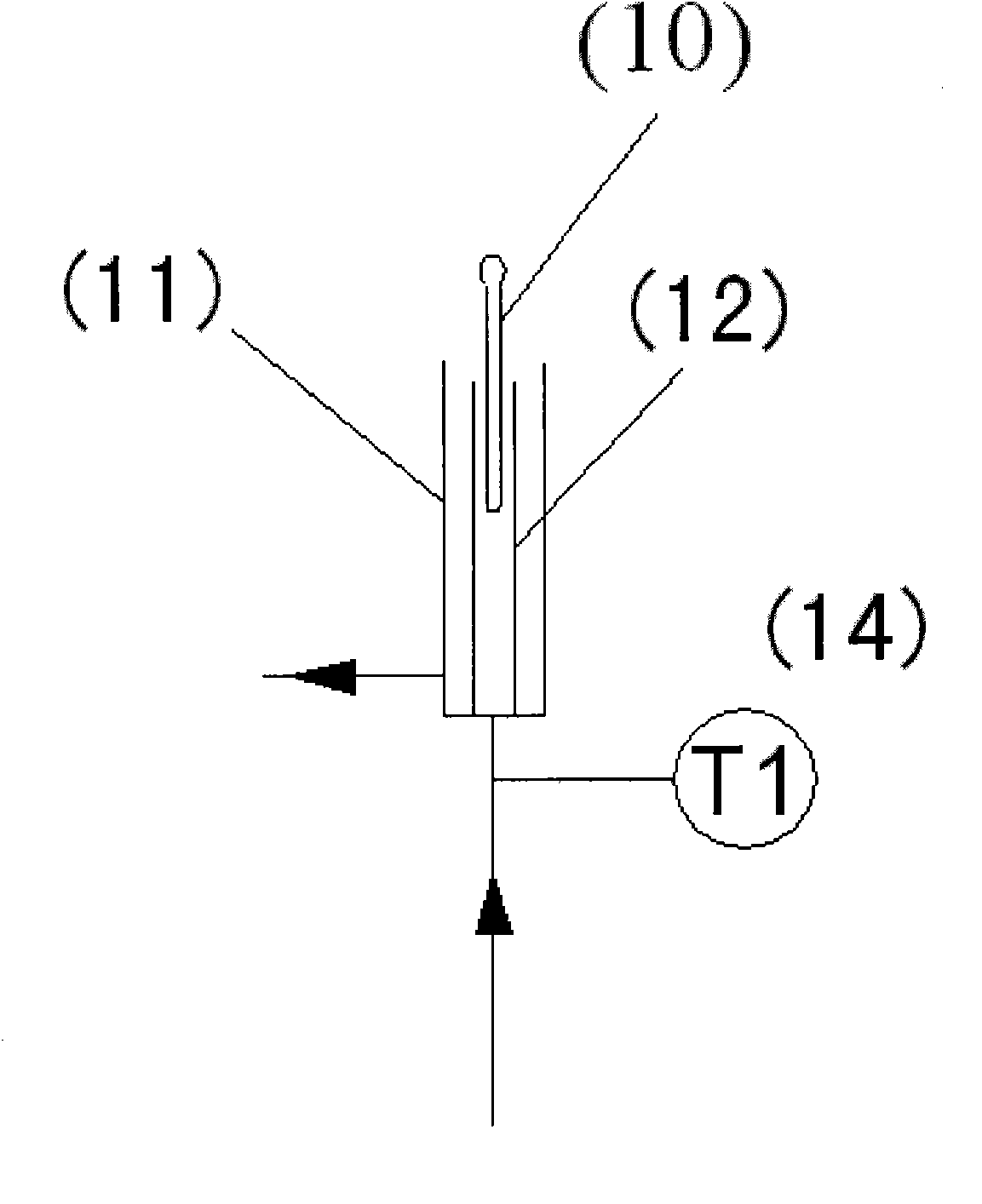

[0010] Such as figure 1 As shown, a rectification experimental device includes a raw material tank 1 fixed on the frame, a tower top product tank 2, a tower kettle product tank 3, a tower kettle 4, a preheater 5, a sieve plate rectification tower 6, and a total condenser 7. Distillation experimental system composed of fractionator 8, feed pump 9 and multi-section stainless steel pipes. Wherein the preheater 5 and the tower kettle 3 are heated by a wet method. The sieve plate rectification tower 6 is fabricated by welding a stainless steel tower body. The total condenser 7 is a tube-and-tube heat exchanger, which is vertically fixed on the top of the tower by means of a flange connection. The transparent glass distillator 8 is welded together with the pipeline through a stainless steel flange. Feed pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com