PCBA (printed circuit board assembly) test bench and application method thereof

A test bench and pallet technology, used in electronic circuit testing, measuring device casings, etc., can solve the problems of uneven force deformation of PCBA board, large deviation of current acquisition value, deviation of probe and reserved TEST point, etc. Effects of preventing electrostatic breakdown, reducing false detection rate, and preventing substrate deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

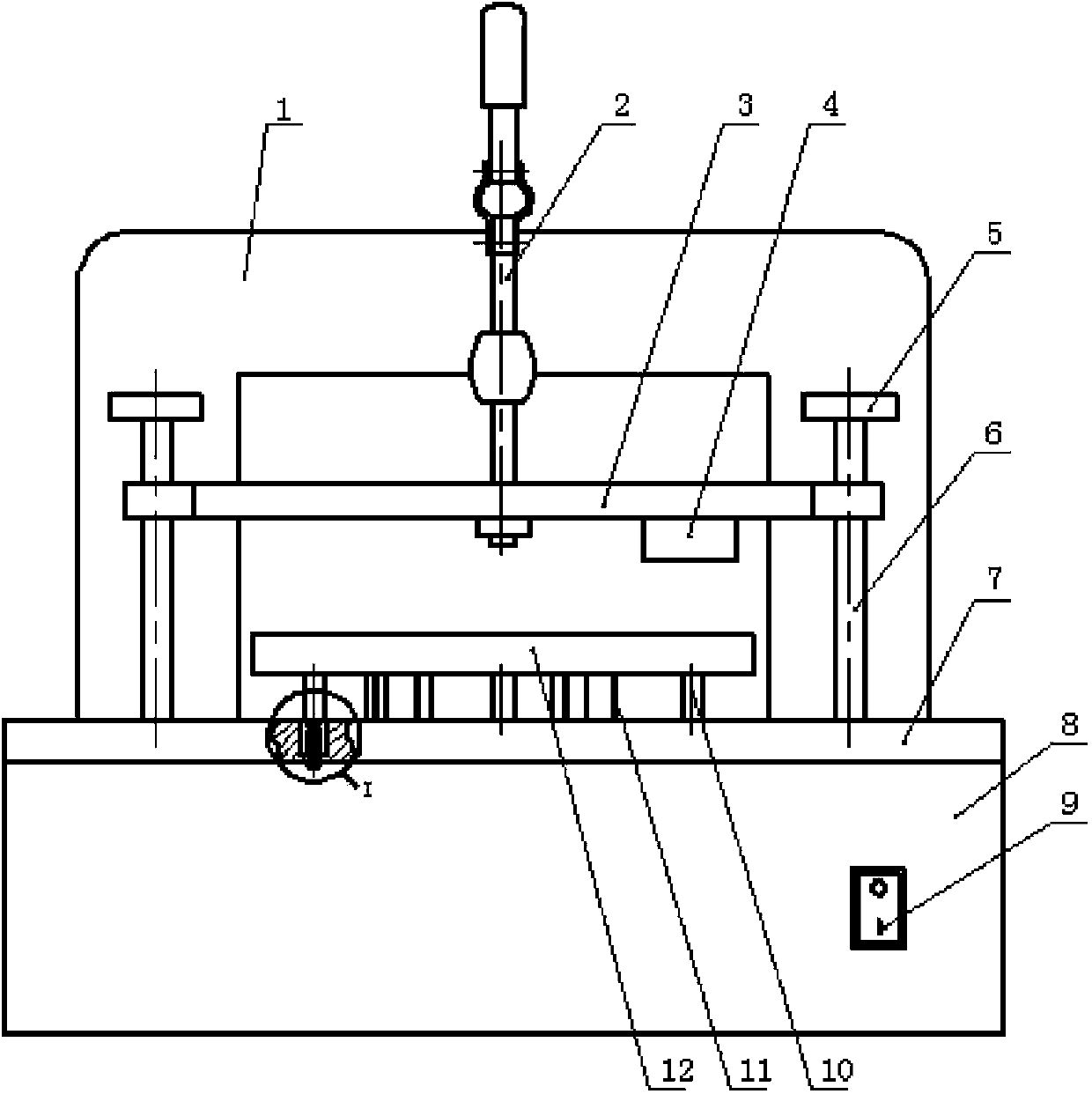

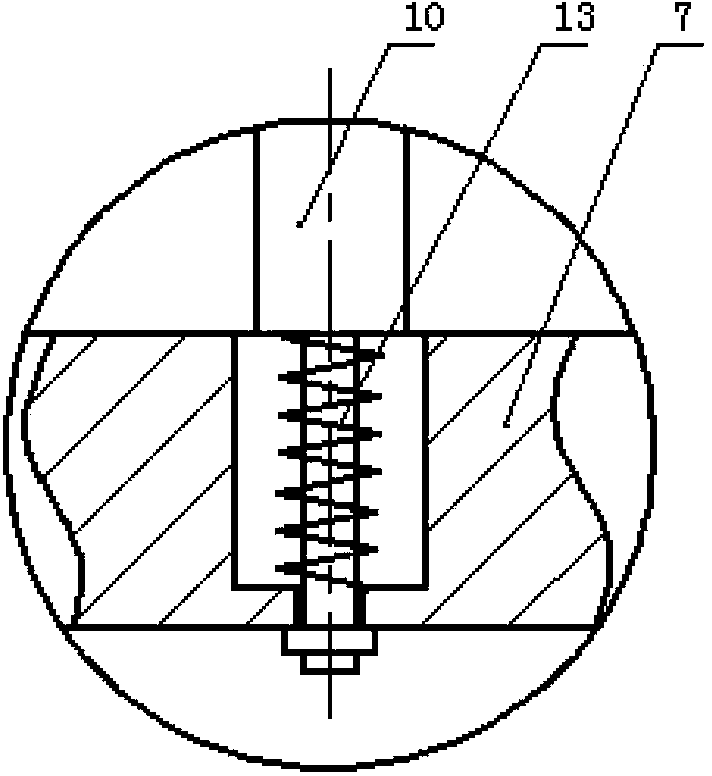

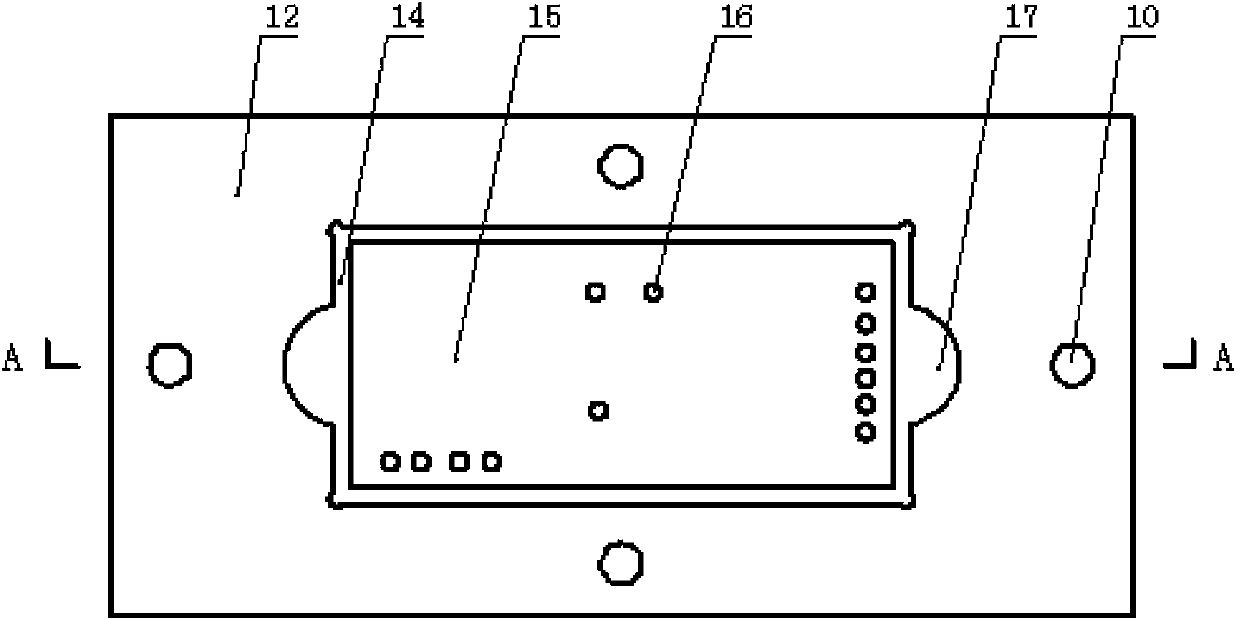

[0024] A PCBA board test bench, such as figure 1 As shown, it includes a control box 8, a needle bed 7, a pallet 12 and a pallet pressing assembly. The control box is a rectangular box structure, and the upper opening of the box is packaged with a needle bed with a rectangular plate structure. A supporting plate pressing assembly is vertically installed on the rear part of the upper end of the bed, and a supporting plate is vertically slidably installed on the needle bed corresponding to the lower end of the supporting plate pressing assembly, and a plurality of probe holes 16 are formed on the supporting plate. for thirteen probe holes, such as figure 2 As shown, the needle bed corresponding to each probe hole is vertically fixed with a probe 11, and the pallet pressing assembly presses down the pallet so that the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com