Continuous casting electro hydraulic servo system signal acquisition monitoring system and signal acquisition monitoring method

An electro-hydraulic servo system and signal acquisition technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of high fault omission rate, insufficient state monitoring ability, long signal sampling period, etc., to improve the effectiveness and speed. performance, improve data collection speed and access efficiency, and reduce equipment downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

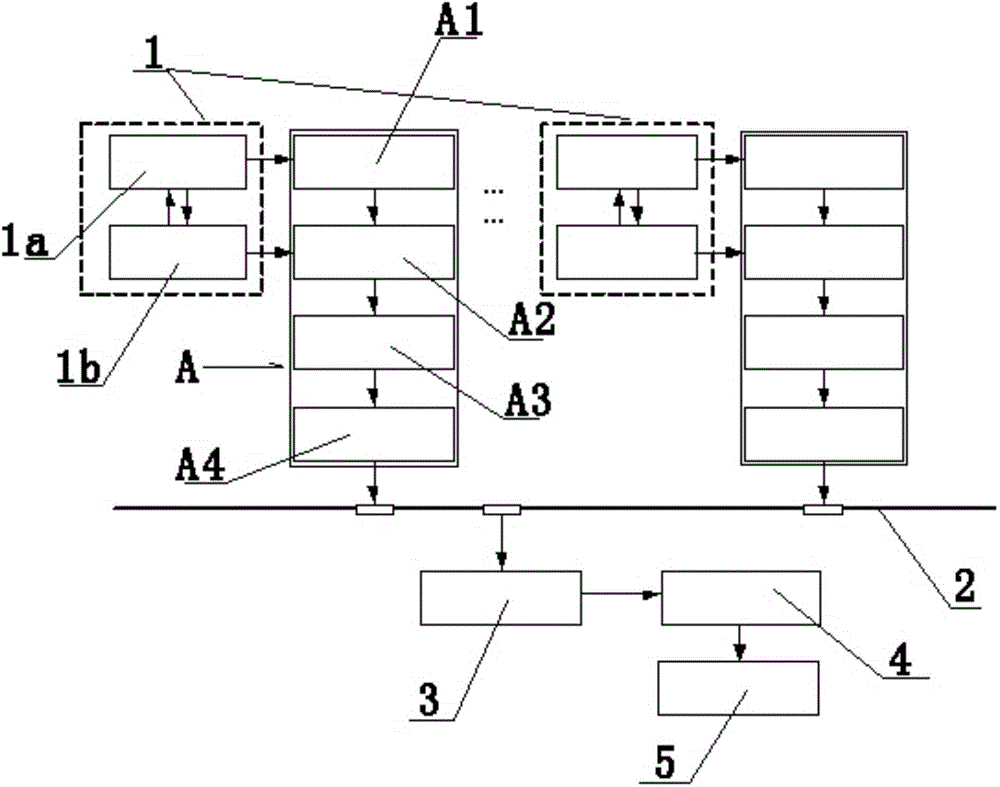

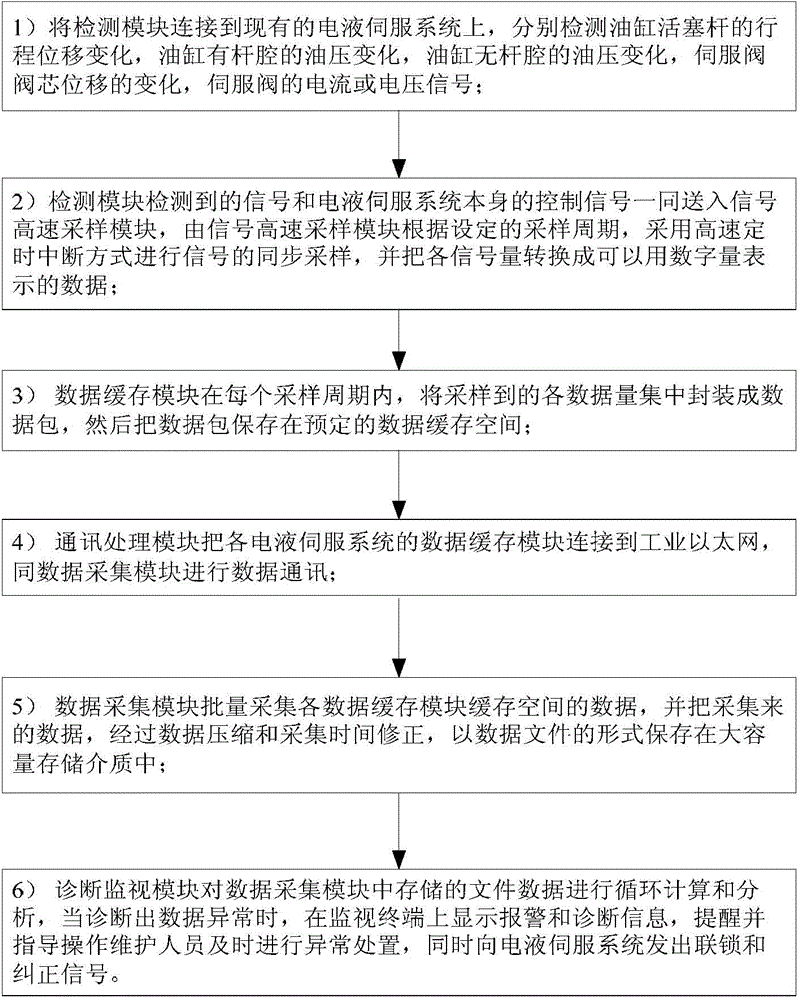

[0081] The signal acquisition and monitoring system and the signal acquisition and monitoring method of the continuous casting electro-hydraulic servo system of the present invention are applied to the six-strand round billet continuous casting tundish slide electro-hydraulic servo system. The electro-hydraulic servo system of the tundish slide in this embodiment total 6 sets, 1 set for each flow, each set of skateboard electro-hydraulic servo system is composed of control system (S7-300 controller), servo valve, skateboard cylinder and other main components.

[0082] (refer to picture 1) Connect the detection module A1 of the signal acquisition and monitoring system A to the actuators 1a such as servo valves and oil cylinders of each existing electro-hydraulic servo device 1, and detect the actual stroke displacement change of the piston rod of the oil cylinder, the rod cavity of the oil cylinder respectively. Changes in the oil pressure of the cylinder rodless cavity, cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com