Infrared/laser/microwave/millimeter wave common-caliber beam forming apparatus

A beam forming device and millimeter-wave technology, applied in the intersecting field of optics and microwave technology, can solve problems such as inability to disassemble, small size, and inability to expand, and achieve the effect of reducing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

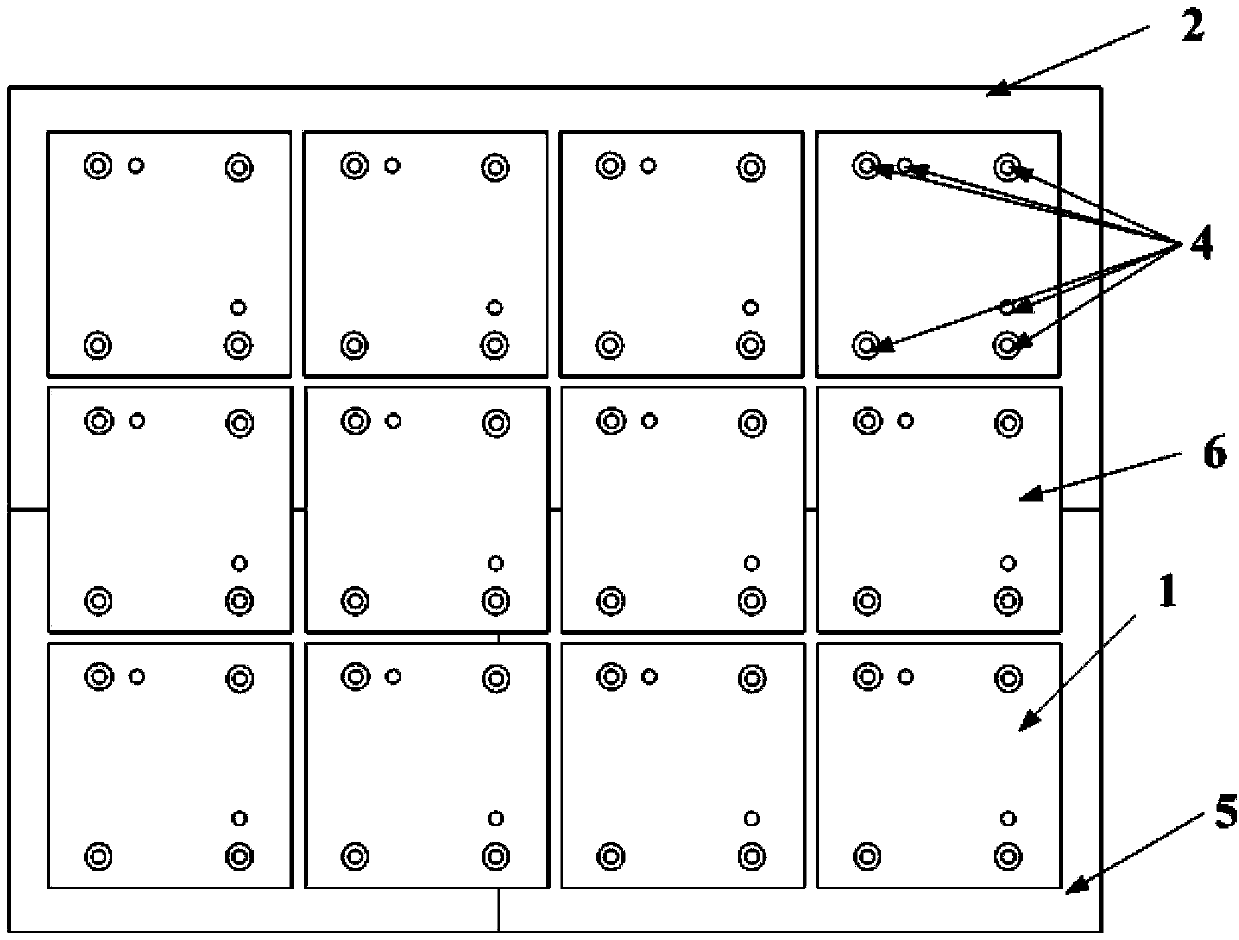

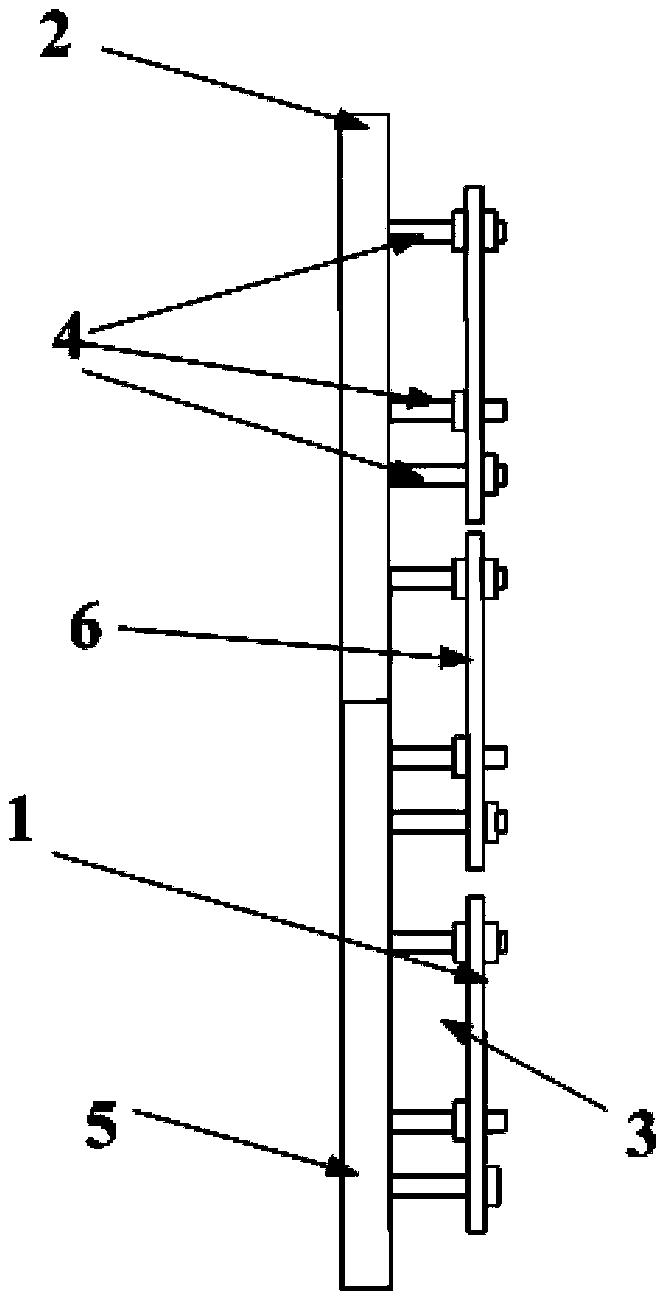

[0029]An infrared / laser / microwave / millimeter wave common-aperture beamforming device in this embodiment includes an infrared / laser reflection plane 1 , a support plate 2 , an air layer 3 , and an adjustment mechanism 4 . The infrared / laser reflection plane is formed by splicing a plurality of sub-chips 5 , and the shape of the spliced infrared / laser reflection plane is determined according to the requirements of beam synthesis. The supporting plate is composed of a plurality of sub-boards 6 , and the shape of the supporting plate after splicing is determined according to the beamforming requirements. An air layer 3 is provided between the infrared / laser reflection plane and the supporting plate. By adjusting the material and thickness of the infrared / laser reflection plane 1, the thickness of the air layer 3, and the material and thickness of the support plate 2, the transmittance within the range of microwave / millimeter wave bands and the range of incident angles can meet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com