Two-dimensional code identification method of matching state of die and clamp

An identification method and two-dimensional code technology, which is applied in the field of two-dimensional code identification in the paired state of molds and fixtures, can solve problems such as time-consuming, cumbersome process, and fixture collision, and achieve the effect of reliable technology, simple method and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

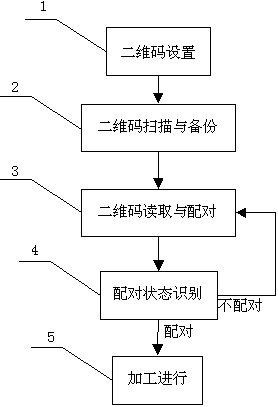

[0012] The present invention will be further described below with reference to the embodiments provided by the accompanying drawings.

[0013] During production, perform the following steps to realize the two-dimensional code identification of the pairing status of the mold and the fixture.

[0014] Step 1, two-dimensional code setting: clean the mold and fixture, and paste an oil-resistant and temperature-resistant two-dimensional barcode on the mold and fixture.

[0015] Step 2, two-dimensional code scanning and backup: start the controller, create a new processing project, use the camera equipped with the machine to scan the two-dimensional code on the mold and fixture, complete the two-dimensional code data saving, adjust the parameters, save the data, and back it up in the memory . Use the machine-equipped camera to scan the QR code on the mold and fixture, log in to the system, save the QR code data, adjust various parameters, save the engineering data, and complete the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com