Circuit board operation system

A circuit substrate and operating system technology, which is applied in the direction of assembling printed circuits, electrical components, electrical components, etc., can solve the inconvenience of operation and maintenance of the circuit substrate handling part and the interior of the equipment, and the inability to easily replace the transport track, circuit Problems such as inconvenient operation and maintenance of the substrate transfer device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

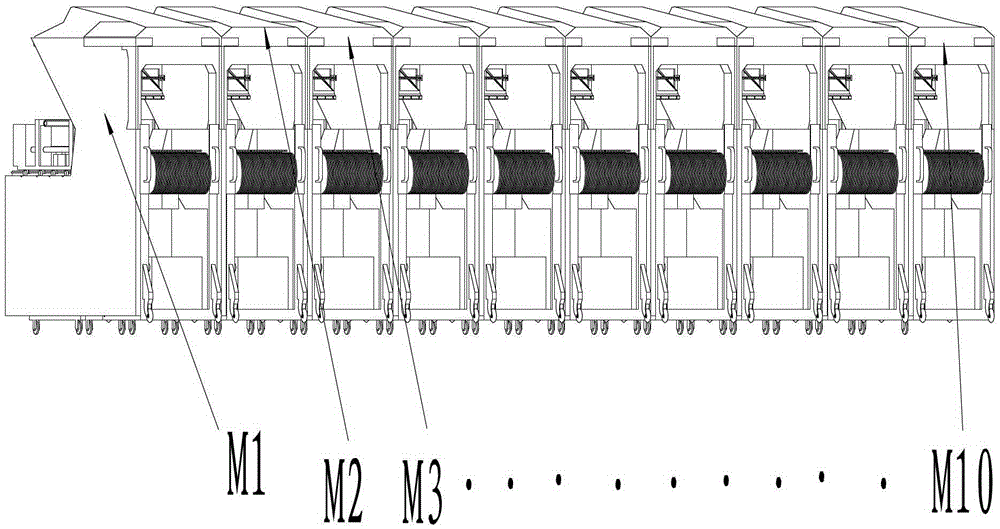

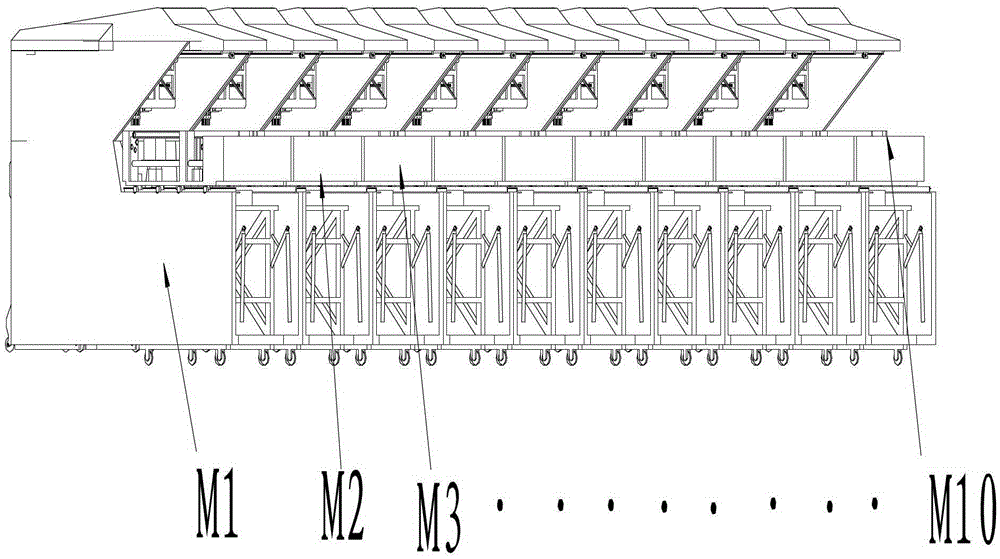

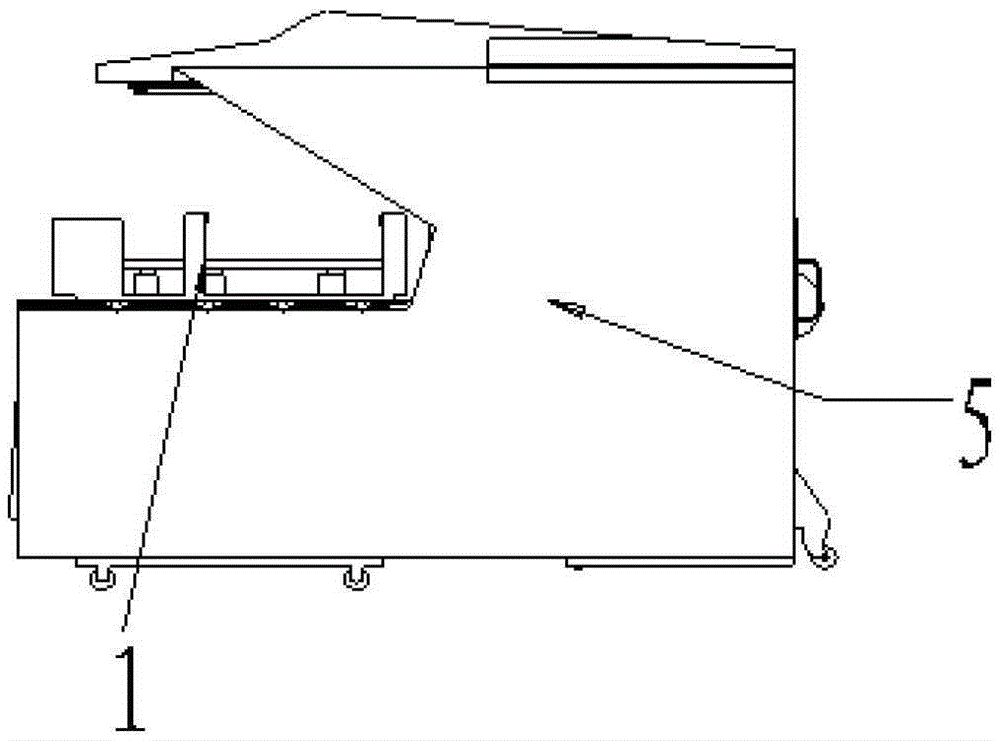

[0081] A circuit substrate operating system, combined with Figure 1 to Figure 27 , wherein M1, M2...M10 are single circuit substrate operating systems, and M1, M2...M10 circuit substrate operating systems are arranged side by side to operate the circuit substrates. Such as image 3 , Figure 4 As shown, it includes a circuit substrate conveying device 1 , a component supply device 2 , an image processing device 3 , a component handling device 4 , and a rack 5 . from Figure 4 It can be seen that the component handling device 4 is installed on the top of the frame 5, the component handling device 4 is provided with an electronic component suction and placement head 404, the circuit substrate conveying device 1, the component supply device 2, the image The processing device 3 is connected to the frame at the lower part of the component handling devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com