Surface covering kit comprising panels and an extraneous locking element

A technology for surface covering and locking elements, applied in the field of ceiling or wall coverings, floors, can solve the problems of difficult insertion, expensive and waste of wedge-shaped connecting elements, and achieve the effect of ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

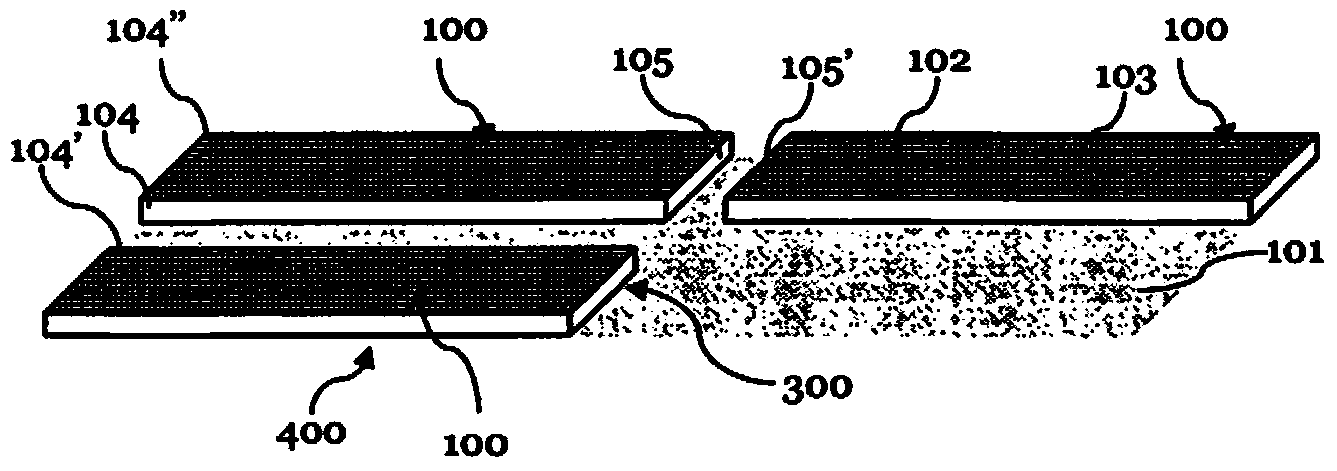

[0082] figure 1 is a schematic diagram showing three exemplary panels 100 laid in a common plane 101 . These panels 100 can be made of any suitable material, however the invention is particularly suitable for laminate panels consisting of HDF (High Density Fibreboard), MDF (Medium Density Fibreboard) or LDF (Low Density Fibreboard). The panel 100 can also be made of wood composite, solid wood, plywood, particle board or OSB (oriented strand board). The panel 100 has an average or mean thickness of between 3mm and 30mm and most preferably between 4mm and 14mm. Due to this simple geometry of the connection elements according to the invention on the lateral sides, they are especially suitable for very thin panels, such as 5 mm flooring laminates.

[0083] The decoration 103 can be provided as a separate decoration layer, for example a decoration printed on paper, or can also be printed directly on the panel 100 . The decoration 103 can be, for example, imitation solid wood, im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com