Blocking-preventing drop catcher and cleaning method thereof

A drip catcher and anti-clogging technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of small cleaning range of the drip catcher and easy blockage of the cone bottom, avoid manual cleaning work, improve Operating environment, the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

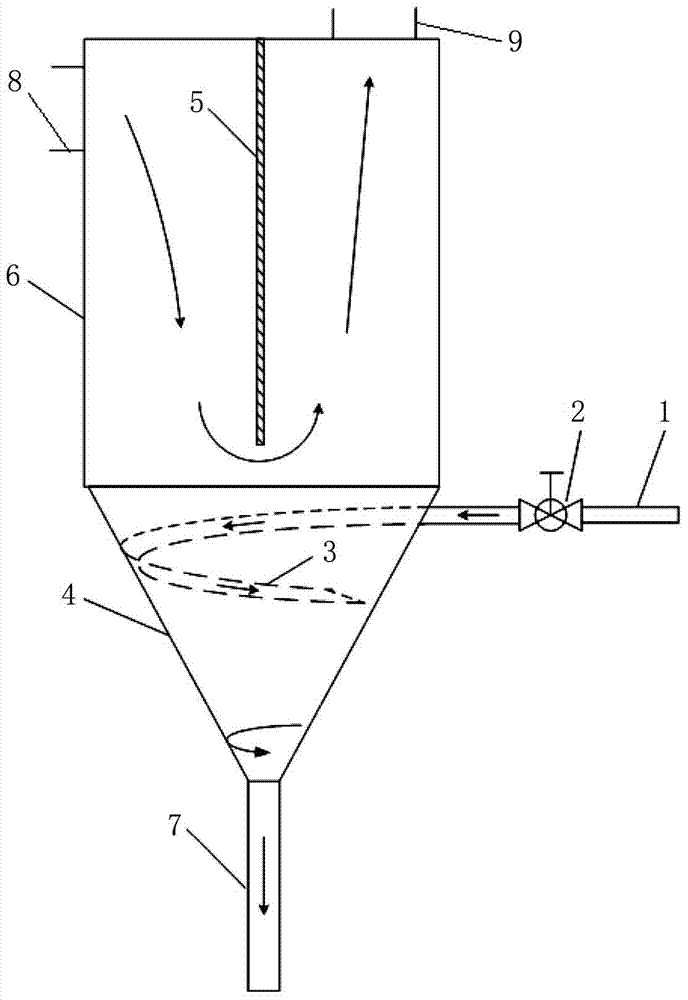

[0018] figure 1 is a schematic structural view of an anti-clogging drip catcher in an exemplary embodiment of the present invention. Such as figure 1 As shown, the anti-clogging drop catcher of the present invention includes a cylinder body 6, a cone bottom 4 and a drain pipe 7, the upper part of the cylinder body 6 is provided with an air inlet 8 and an air outlet 9 and a partition plate 5 is arranged in the cylinder body 6 , The cone bottom 4 is arranged at the lower end of the cylinder 6, and the drain pipe 7 is arranged at the lower end of the cone bottom 4, and the cylinder 6, the cone bottom 4 and the drain pipe 7 communicate with each other. Moreover, the air inlet 8 and the air outlet 9 are respectively located on both sides of the partition plate 5. When the exhaust gas enters the cylinder body 6 through the air inlet 8, under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com