Double-direction perspective film and manufacturing method thereof

A manufacturing method and technology of see-through film, applied in the field of see-through film, can solve the problems of high cost, inability to store for a long time, low production efficiency, etc., achieve stable quality, and meet the effect of light transmission and see-through effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

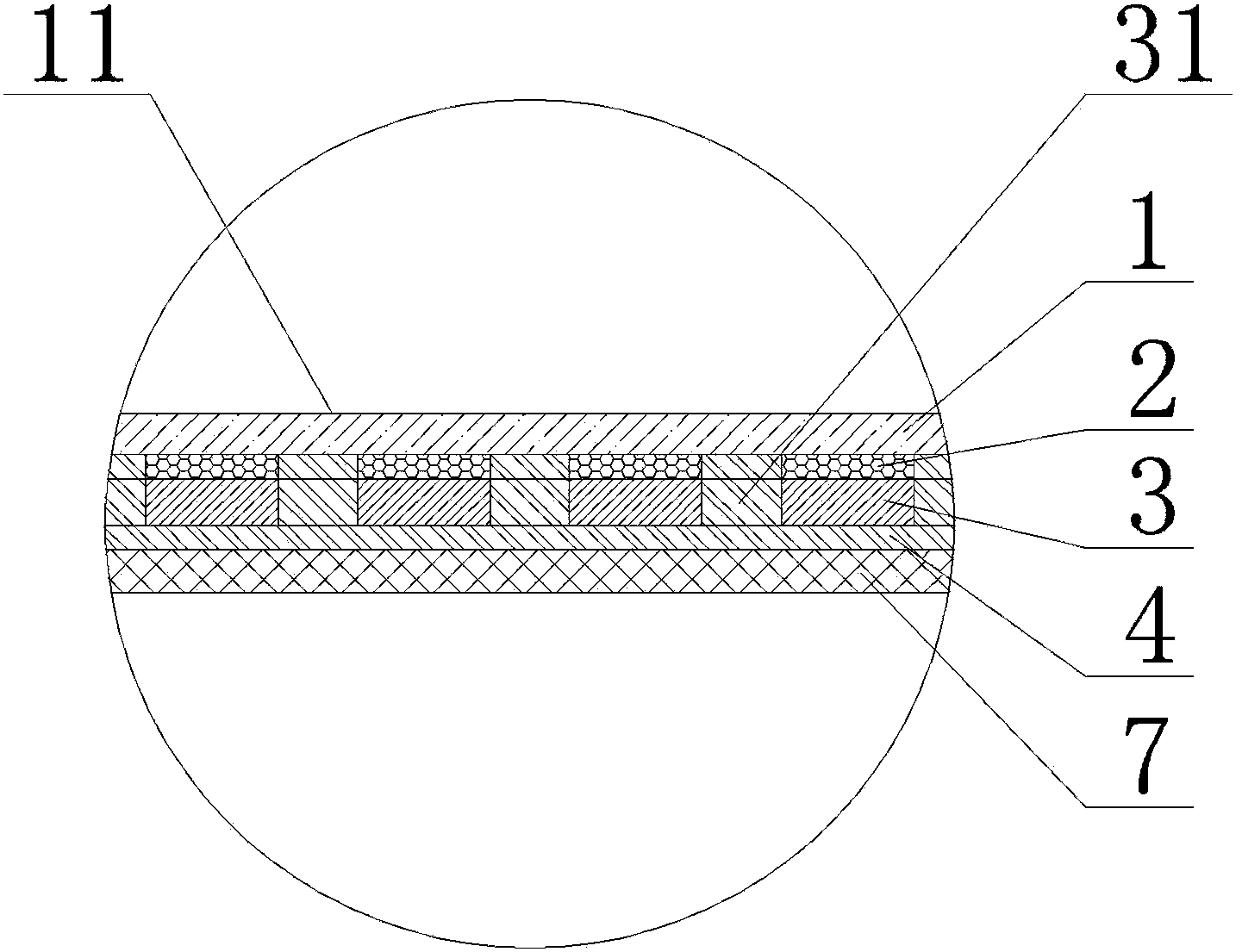

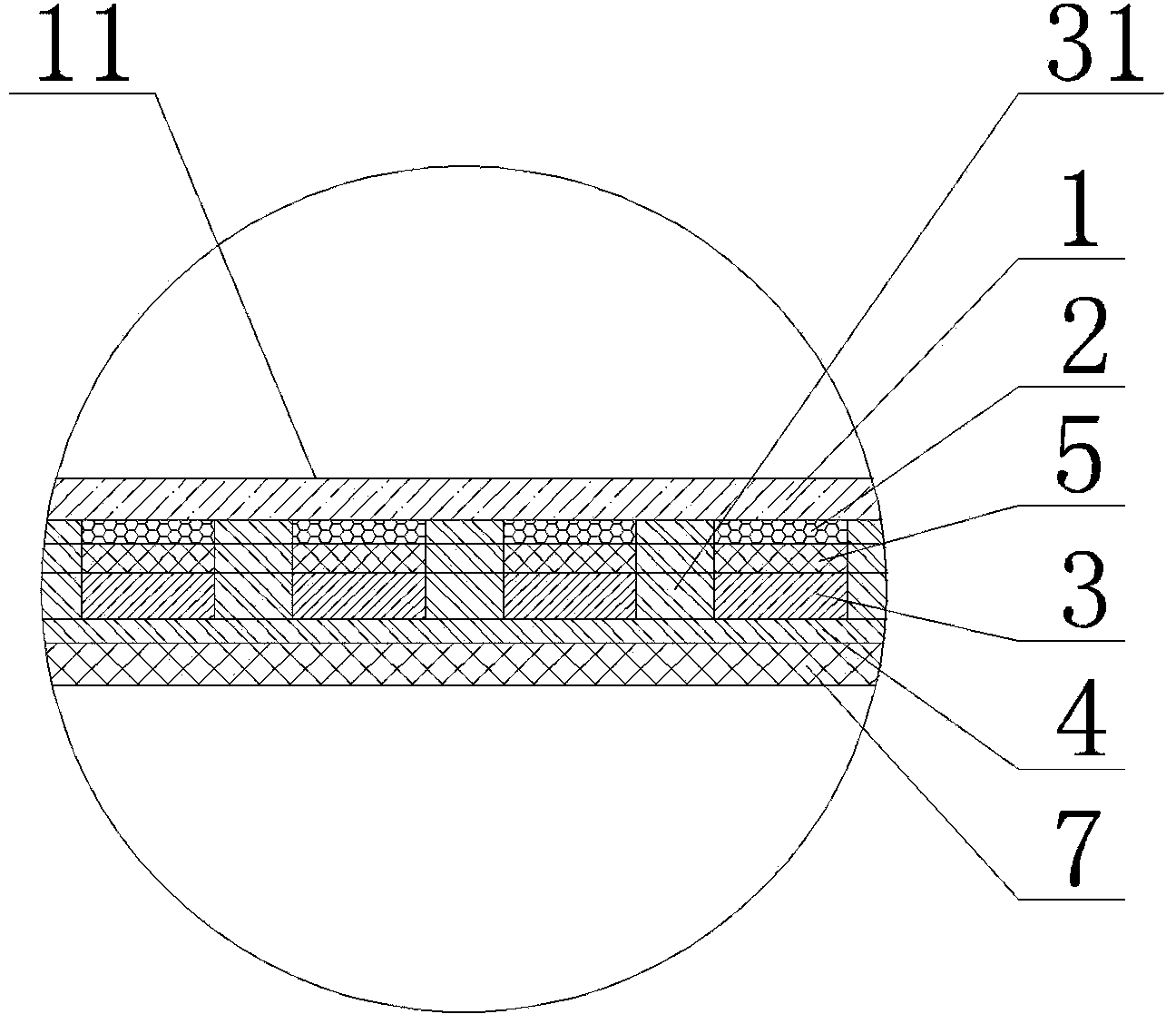

[0059] Such as Figure 1-Figure 4 , Figure 18-Figure 23 and Figure 26 As shown, the two-way see-through film of the present invention includes a transparent film 1, an adhesive layer 2, a metal layer 3, an adhesive layer 4 and a protective layer 7 arranged in sequence, wherein the metal layer 3 is generally vacuum aluminum-plated The metal layer 3 is distributed with a light-transmitting area 31, the light-transmitting area 31 penetrates the adhesive layer 2, and the part of the adhesive layer 4 located in the light-transmitting area 31 penetrates the light-transmitting area. The area 31 is set on the transparent film 1, the outer surface 11 of the transparent film 1 is an inking surface that can be printed or spray-painted, and the adhesive layer 4 can be a transparent self-adhesive layer, and the protective layer 7 is a backing paper or release paper. Due to the clever use of the structure of the metal layer, the present invention makes use of the extremely strong cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com