Method for regulating speed of railway plane glide and preventing car overrunning in humping

A flat sliding and hump sliding technology, which is applied in the field of automatic speed regulation and anti-slip control, can solve the problems of low labor efficiency, iron shoe safety hazards, and low efficiency, so as to improve labor productivity, reduce operators, and reduce safety. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

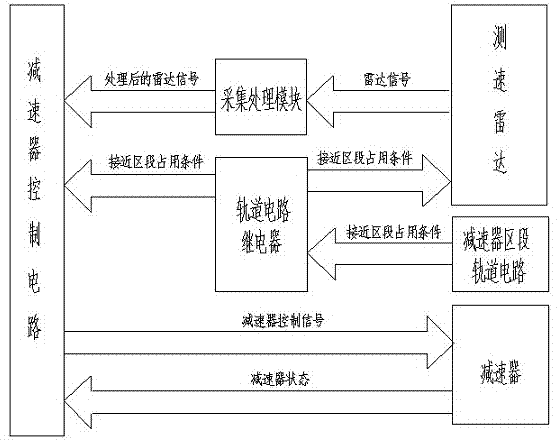

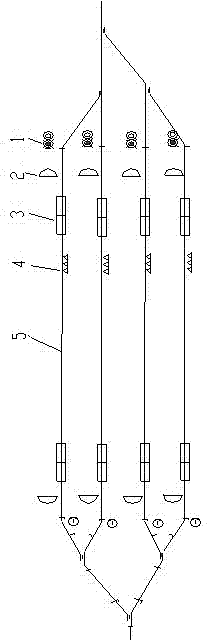

[0016] The method of the present invention is as follows: a clamp-type reducer is installed at the entrance of the tail-end track and 80 to 120 m away from the shunting signal machine of the tail-end track, and the clamp-type reducer is set at the terminal of the target area of the clamp-type reducer to the slope change point. Speed reduction roof, set the speed measuring radar between the shunting signal machine and the clamp-type reducer, set the reducer section track circuit and the clamp-type reducer control circuit at the installation position of the clamp-type reducer, the track circuit of the reducer section The output is connected to the input of the speed-measuring radar, and the output of the speed-measuring radar is connected to the input of the control circuit of the clamp-type reducer; in the tailing plane sliding operation, the speed-reducing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com