High-precision conveying metering system of multi-hole granular ammonium nitrate fuel oil mixture site mixed-loading vehicle

A metering system, the technology of ammonium explosives, applied in the directions of explosives, conveyors, conveyor objects, etc., can solve the problems of easy to add several kilograms, large errors, affecting the quality of blasting projects, etc., to improve stability and accuracy, Eliminates the effect of missing pulse signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

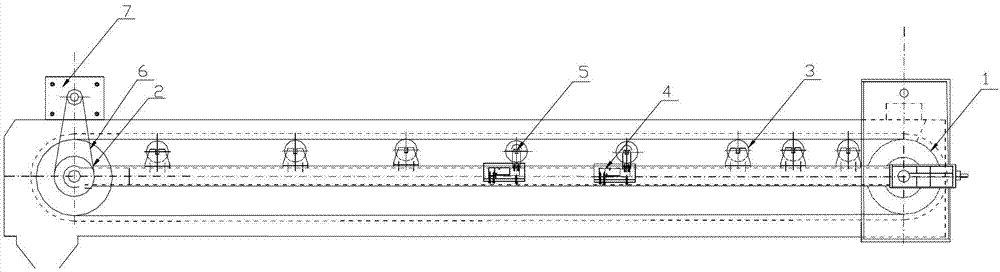

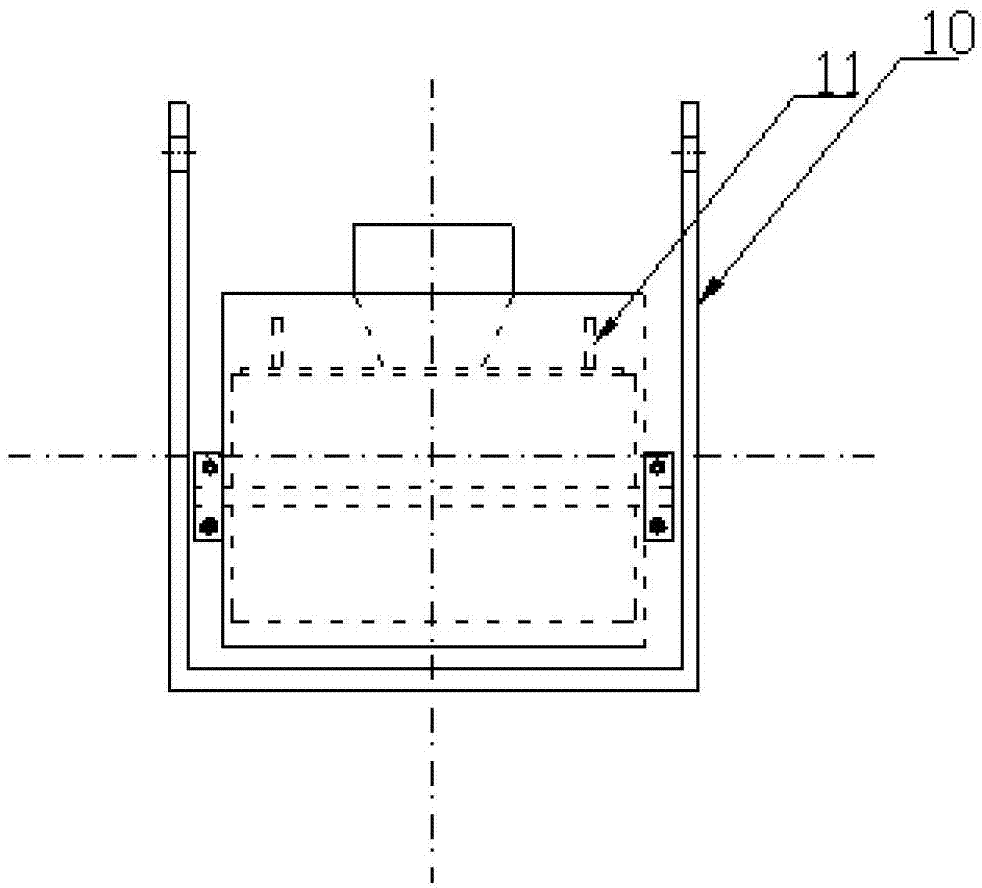

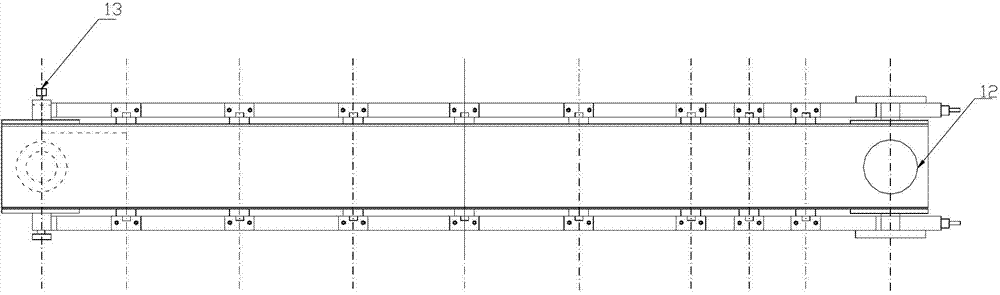

[0019] The high-precision porous granular ammonium explosive on-site mixed loading vehicle delivery metering system 15 of the present invention uses a belt conveyor. The belt conveyor is provided with a shell to form a fully enclosed belt conveyor. The material is all stainless steel (304 material) to improve the intrinsic safety. The side screw 9 of the metering system 15 and the on-site mixed loading vehicle 14 for porous granular ammonium explosives (hereinafter referred to as the mixed loading vehicle) is suspended on the left side of the mixed loading vehicle 14 (the vehicle is moving in the forward direction) through a suspension bracket 10 and steel pins. Ammonium nitrate and diesel fuel are mixed with the side screw 9 of the mixing truck 14 and then lifted to the discharge port 16 of the side screw 9 of the mixing truck and then transported to the metering system 15.

[0020] Two load cells 4 are installed on the sensor roller 5 of the fully enclosed belt conveyor. The loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com