Dealcoholized silicone sealant and preparation method thereof

A silicone sealant, dealcoholization technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problems of transparency, unsatisfactory yellowing, unstable storage, and adhesiveness to be improved, etc. Achieve the effects of poor compatibility, high transparency and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

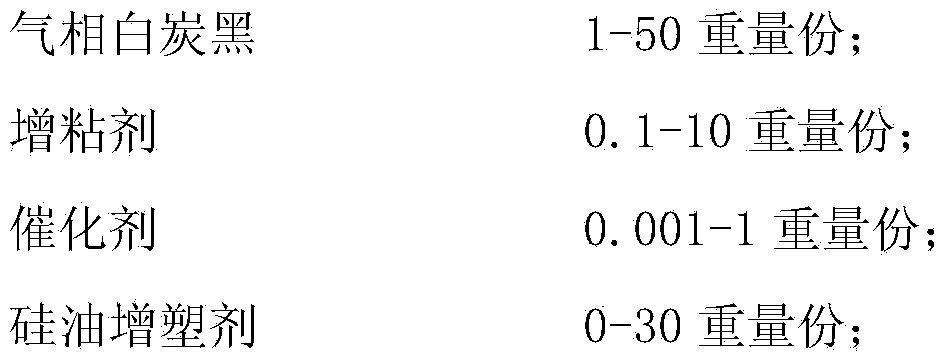

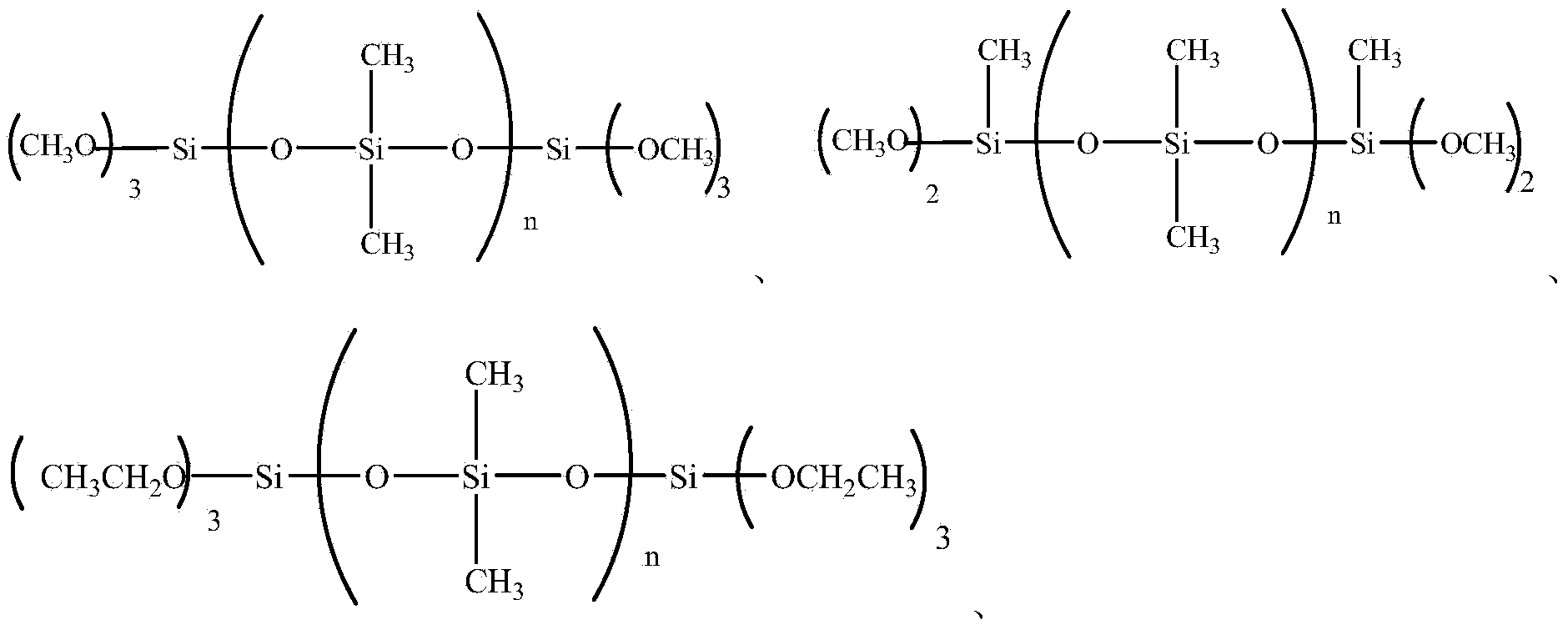

Method used

Image

Examples

Embodiment 1

[0025] Example 1: 100 parts of trimethoxysiloxy polydimethylsiloxane with a viscosity of 10Pa·S at 25°C, 10 parts of morpholinomethyltrimethoxysilane, and a BET specific surface area of 150m 2 / g of hydrophilic fumed silica 11 parts, γ-aminopropyltrimethoxysilane 1 part, γ-glycidoxypropyltrimethoxysilane 0.5 parts, di-n-butyltin diacetate 0.02 parts Add 5 parts of polydimethylsiloxane with a molecular end methyl group with a viscosity of 0.1Pa·S at 25°C into a planetary mixer and mix at high speed for 60 minutes under anhydrous conditions to make dealcoholized silicone sealant. Store in a sealed dry plastic bottle.

Embodiment 2

[0026] Example 2: 50 parts of triethoxysiloxy polydimethylsiloxane with a viscosity of 1.5 Pa·S at 25°C and a diethoxymethylsiloxy with a viscosity of 1 Pa·S at 25°C 50 parts of polydimethylsiloxane, 16 parts of morpholinomethyltrimethoxysilane, BET specific surface area 150m 2 / g of hydrophobic fumed white carbon black treated with silazane on the surface, 0.5 part of N-(β-aminoethyl)-γ-aminopropyltriethoxysilane, 0.29 part of di-n-butyltin diacetate , 25 ℃ viscosity of 2Pa·S molecular terminal methyl polydimethylsiloxane 20 parts into the planetary mixer, under anhydrous conditions, high-speed mixing for 80 minutes to make dealcoholized silicone sealant, save In a sealed dry plastic bottle.

Embodiment 3

[0027] Example 3: 30 parts of triethoxysiloxy polydimethylsiloxane with a viscosity of 20 Pa·S at 25°C and a diethoxymethylsiloxy polydimethylsiloxane with a viscosity of 80 Pa·S at 25°C 70 parts of dimethylsiloxane, 5 parts of morpholinomethyltriethoxysilane, BET specific surface area 150m 2 / g of hydrophobic fumed silica treated with octamethyltetracyclosiloxane, 1 part of γ-aminopropyltriethoxysilane, 0.4 part of di-n-butyltin dilaurate, viscosity at 25°C Add 5 parts of 2Pa·S molecular terminal methyl polydimethylsiloxane into a planetary mixer, mix at high speed for 110 minutes under anhydrous conditions, to make dealcoholized silicone sealant, and store it in a sealed dry plastic In the bottle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com