Preparation method of high-dispersity titanium catalyst for polyester synthesis

A titanium-based catalyst and high-dispersity technology, applied in the field of high-dispersity titanium-based catalyst preparation, can solve the problems of poor polyester hue, prolonged polyester synthesis time, and increased by-products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

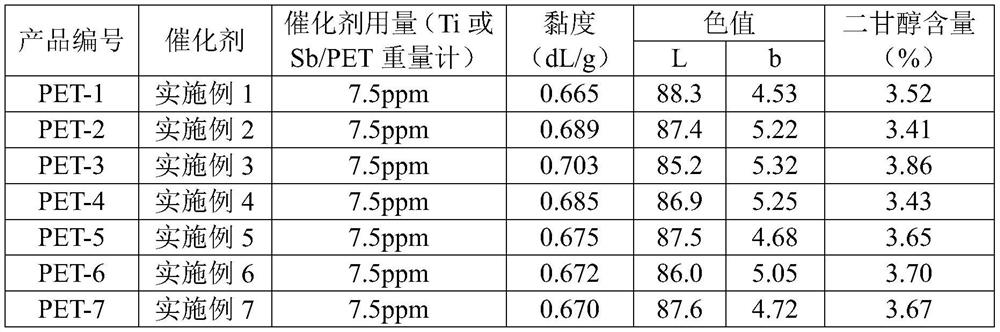

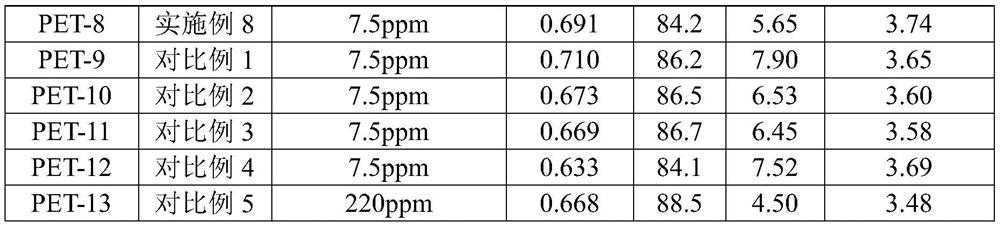

Examples

preparation example Construction

[0028] A method for preparing a highly dispersed titanium-based catalyst for polyester synthesis, comprising the following steps: adding water, titanate compounds, organic guanidine compounds and silica gel to form a reaction system in a solvent system composed of organic alcohols, and carrying out The hydrolysis reaction of titanate yields a highly dispersed titanium-based catalyst.

[0029] Described organic alcohol is monohydric alcohol and / or polyhydric alcohol; Described monohydric alcohol is one or more in methanol, ethanol, propanol, butanol, pentanol, and described polyhydric alcohol is ethylene glycol, propylene glycol, glycerine One or more of alcohol, butylene glycol, and isoprene glycol. The titanate compound is ethyl titanate and / or butyl titanate. The organic guanidine compounds are monoguanidine compounds and / or polyguanidine compounds. The specific surface area of the silica gel is greater than 50m 2 / g, the particle size is less than 200nm.

[0030] The ...

Embodiment 1

[0032] A method for preparing a highly dispersed titanium-based catalyst for polyester synthesis, comprising the following steps:

[0033] Add 250mL of ethylene glycol into the three-necked bottle, add 10g of water, 0.5g of guanidine phosphate, and 2g of silica gel (the specific surface area is 200m 2 / g, the average particle size is 10nm). After stirring evenly, 1 g of butyl titanate was added dropwise, and the reaction was stirred for 48 hours to obtain a highly dispersed titanium-based catalyst.

Embodiment 2

[0035] A method for preparing a highly dispersed titanium-based catalyst for polyester synthesis, comprising the following steps:

[0036] Add 250mL of methanol into the three-necked flask, then add 5g of water, 0.1g of guanidine carbonate, and 2g of silica gel (the specific surface area is 200m 2 / g, the average particle size is 10nm). After uniform stirring, 2 g of butyl titanate was added dropwise, and the reaction was stirred for 60 hours to obtain a highly dispersed titanium-based catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com