Insulating sling and manufacturing method thereof

A production method and sling technology, which are applied in the directions of dyeing, textile and papermaking, overhead line/cable equipment, etc., to achieve the effect of saving time in processing, convenient assembly and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

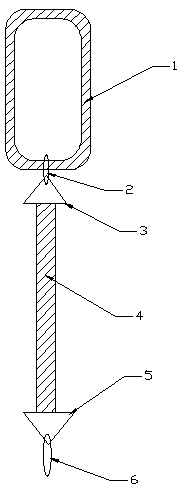

[0042] Connect the hanging plate 1, the connecting ring 2, the first triangular hook 3, the sling 4, the second triangular hook 5 and the circular hanging ring 6 in order, and use the hanging plate 1 and the circular hanging ring 6 to connect with other The parts are connected and fixed.

[0043] Among them, the sling 4 can be equipped with reflective strips or LED strobe lights on its surface before use, and the position can be prompted during night construction. The sling 4 made by the present invention has the effects of long fiber, no impurities, electrical insulation and flame retardancy Well, it meets the requirements of the actual construction work on safe construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com