Steeply inclined coal seam strike long-wall mechanization mining method

A mining method and steeply inclined technology, which is applied in the field of steeply inclined coal seam to longwall mining, can solve the problems of high coal loss rate, low mining efficiency, high labor intensity, etc., and achieve high recovery rate, wide application range and high degree of mechanization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

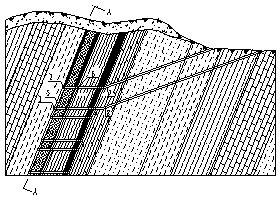

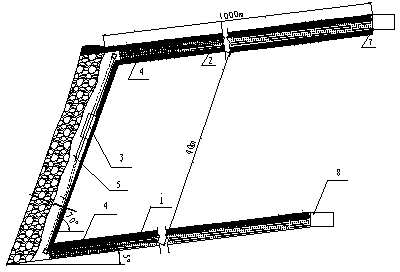

[0019] Such as figure 1 , 2 As shown, a kind of steeply inclined coal seam moves toward the longwall mechanized mining method, and the specific steps are as follows:

[0020] (1) Along the trend of the steeply inclined coal seam, two recovery roadways, the transportation channel 1 and the return air channel 2, are arranged in parallel at an upper and lower interval of 40m. 5°;

[0021] (2) When the mining roadway is excavated to the design position, the mining face 5 is excavated from the upper and lower sides along the coal seam inclination, and the mining face is 70° from the horizontal direction to form a longwall mining system;

[0022] (3) After the mining face is excavated, a chain-driven coal plow 3 is installed at the end of the mining face to carry out normal coal mining operations.

[0023] (4) The coal blocks planed by the coal plow slide down to the lower part along the inclined working surface, and then transported to the section transport roadway 8 through the...

Embodiment 2

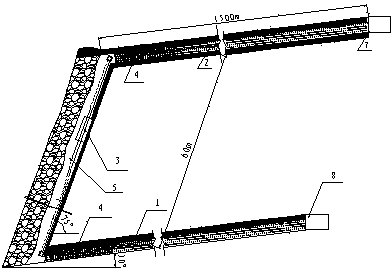

[0032] Such as figure 1 , 3 As shown, a kind of steeply inclined coal seam moves toward the longwall mechanized mining method, and the specific steps are as follows:

[0033] (1) Along the trend of the steeply inclined coal seam, two recovery roadways, the transportation channel 1 and the return air channel 2, are arranged in parallel at an upper and lower interval of 60m. The mining roadway is 1500m long and slopes slightly downward along the coal seam at 10° to the horizontal direction;

[0034] (2) When the mining roadway is excavated to the design position, the mining face 5 is excavated from the upper and lower sides along the coal seam inclination, and the mining face is 75° from the horizontal direction, forming a longwall mining system;

[0035] (3) After the mining face is excavated, a chain-driven coal plow 3 is installed at the end of the mining face to carry out normal coal mining operations.

[0036] (4) The coal blocks planed by the coal plow slide down to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com