Damping spring

A shock-absorbing spring and coil spring technology, applied in the field of shock absorber springs, can solve problems such as poor comfort, achieve the effect of optimizing structure and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in detail below through the examples. It should be understood that the following examples are exemplary only, and can only be used to explain and illustrate the technical solution of the present invention, and cannot be interpreted as the technical solution of the present invention. limits.

[0021] The technical solution of the present invention is only applicable to coil springs.

[0022] In the present invention, from the bottom of the coil spring to the top means that the distance between the top and the vehicle body is close, and the distance between the bottom and the ground is close.

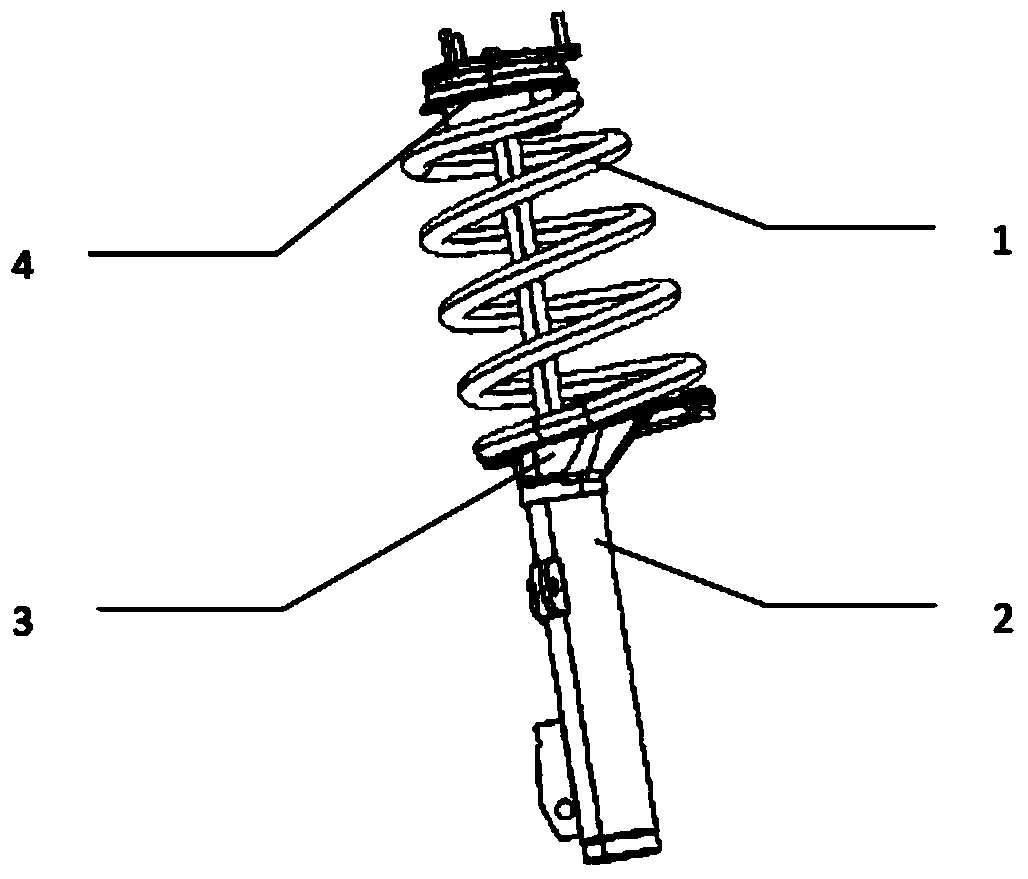

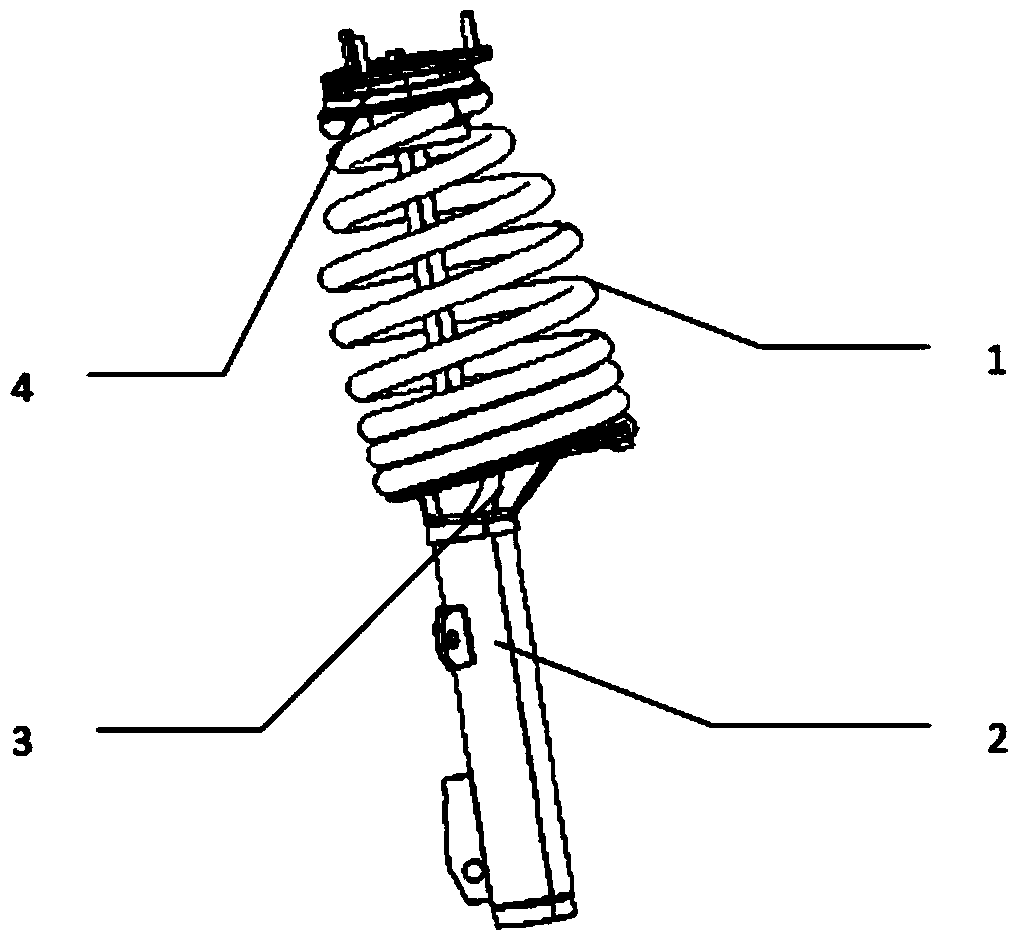

[0023] Such as image 3 As shown, the suspension front damping spring of the present invention is also made up of a shock absorber and a coil spring, wherein the coil spring 1 is assembled on the shock absorber body 2, and the spring holder 3 welded on the shock absorber body 2 and the shock absorber The upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com