Laser Rockwell hardness standard device and measuring method

A Rockwell hardness and standard device technology, applied in the direction of measuring device, test material hardness, strength characteristics, etc., can solve the problems of low degree of automation, low measurement accuracy, and difficult stability guarantee, and achieve high accuracy and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

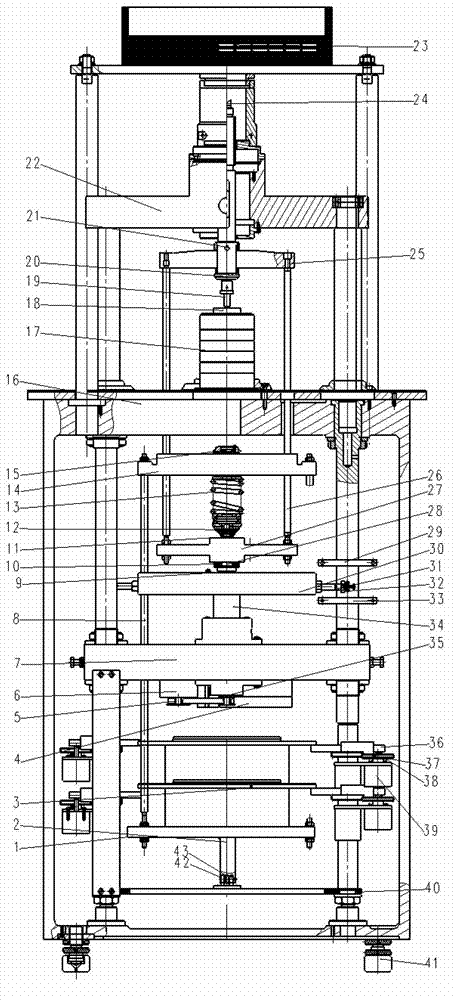

[0037] In the following, the present invention will be further described in detail through specific embodiments with reference to the drawings: figure 1 As shown, the intelligent loading laser Rockwell hardness standard device includes a spindle system, a power system, a force loading system, a frame support system, and a depth measurement system;

[0038] A main shaft 20 and a ball spline guide system 21 are provided inside the main shaft system;

[0039] The power system is provided with a servo motor 4, a ball screw transmission system, and a guide wheel frame 30, a sensor 9 and a bearing shaft 28 are provided on the ball screw transmission system;

[0040] The force loading system is equipped with a two-stage suspension, and the two-stage suspension includes a first-stage suspension and a second-stage suspension; the first-stage suspension includes an upper boom 26, an upper beam 25 and a lower beam 27; The secondary hanger acts on the primary hanger through the buffer spring 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com