A battery tab detection method and detection system based on machine vision

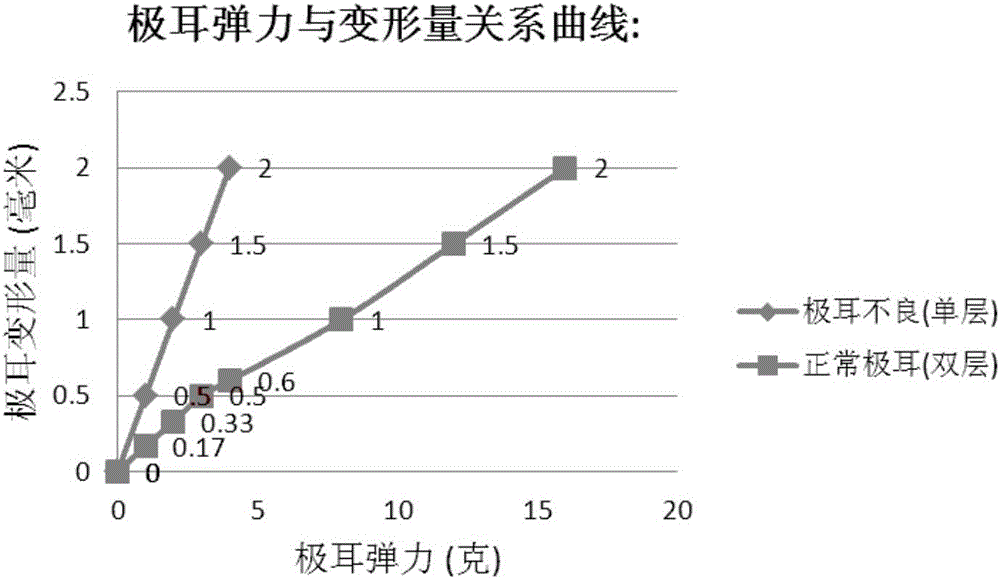

A battery tab and machine vision technology, applied in the direction of optical testing flaws/defects, can solve the problems of single-layer battery tabs, low efficiency, and high missed detection rate, saving human capital, high measurement accuracy, and fast measurement speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

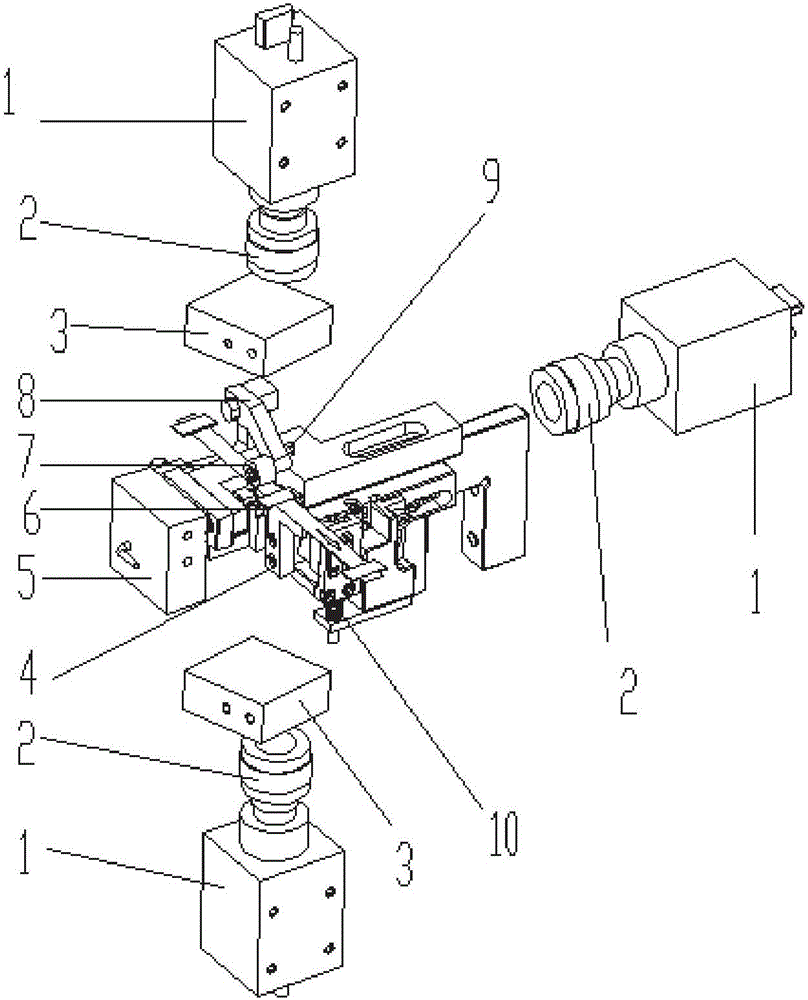

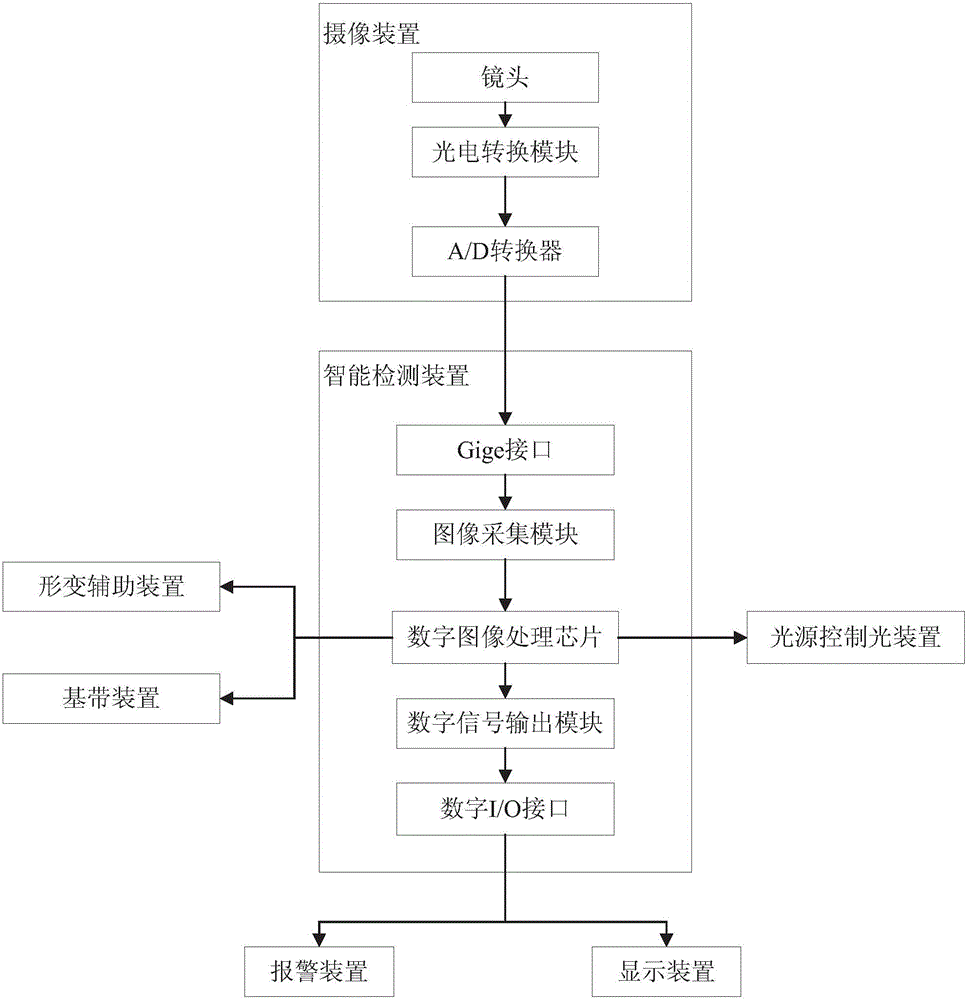

[0052] see Figure 1 to Figure 4 , the present invention provides a battery tab detection method based on machine vision, which includes the following steps:

[0053] (1) Three sets of camera devices 1 are respectively arranged to collect the perspective images of the front, back and side of the battery tab 6 respectively;

[0054] (2) Three sets of light source control devices and three sets of light sources connected to the devices are respectively provided, and the light source control devices are used to adjust the irradiation brightness of the light source so that the light source produces a uniform light-emitting surface;

[0055] (3) A baseband device for stabilizing the battery tab 6 is provided so that the battery tab 6 to be tested remains stable when it is in the detected position;

[0056] (4) A deformation auxiliary device is provided to cause predetermined deformation of the battery tab 6 to be tested;

[0057] (5) A display device is provided to display the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com