Field operation optimization method for SCR (selective catalytic reduction) denitration system

A technology of on-site operation and optimization method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as low efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

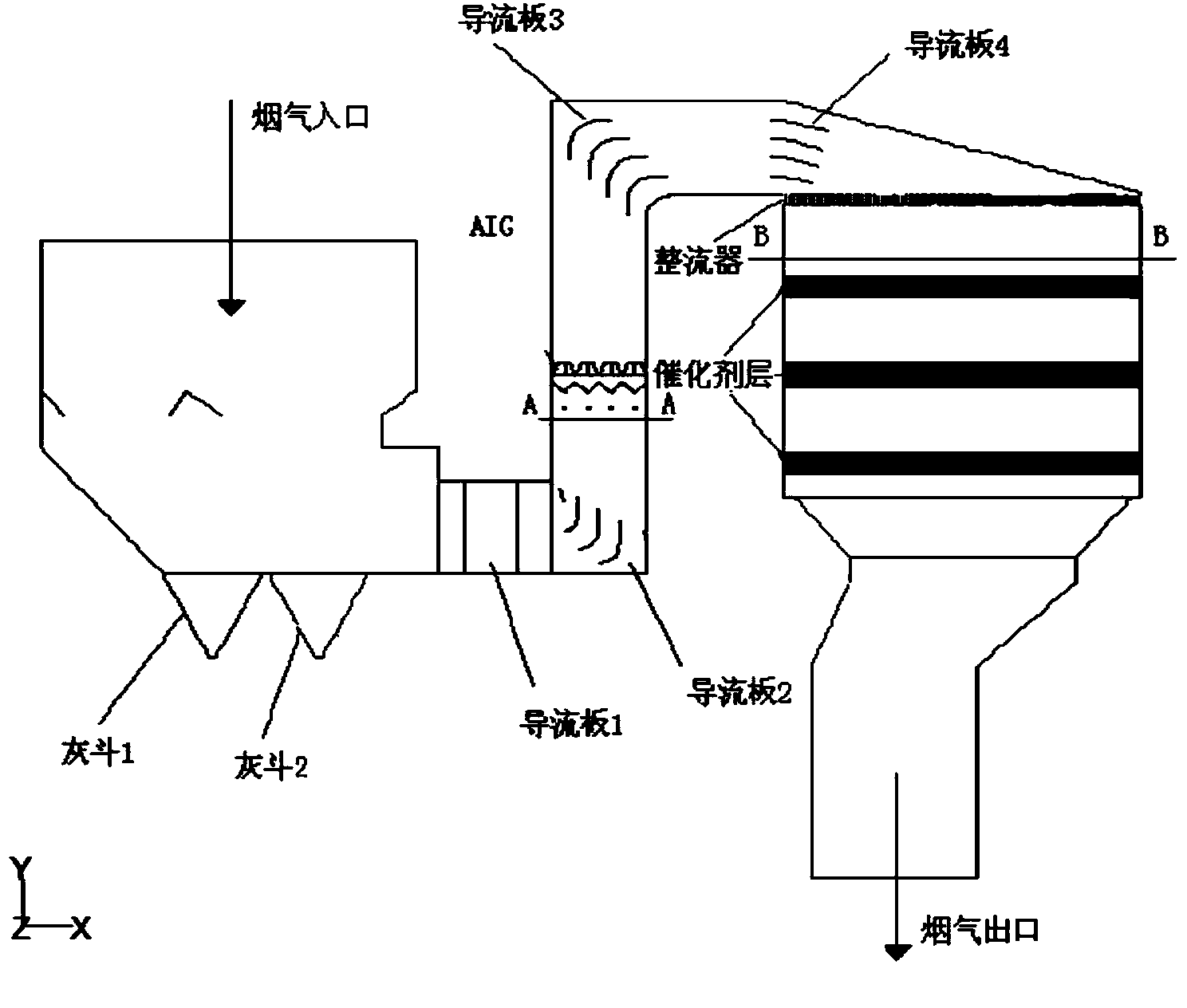

[0052] The specific implementation of the on-site operation optimization method of the SCR denitrification system of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0053] refer to figure 1 as shown, figure 1 It is a partial structural diagram of the SCR denitrification system. The figure shows the part from the flue gas inlet to the flue gas outlet, including the ash hopper, the flue and the reactor. Among them, the reactor is equipped with a rectifier and a catalyst layer. Its working principle is: By adding ammonia to the flue gas at a certain temperature, under the action of a catalyst, it can selectively reduce and react with NO to form N2 and H2O.

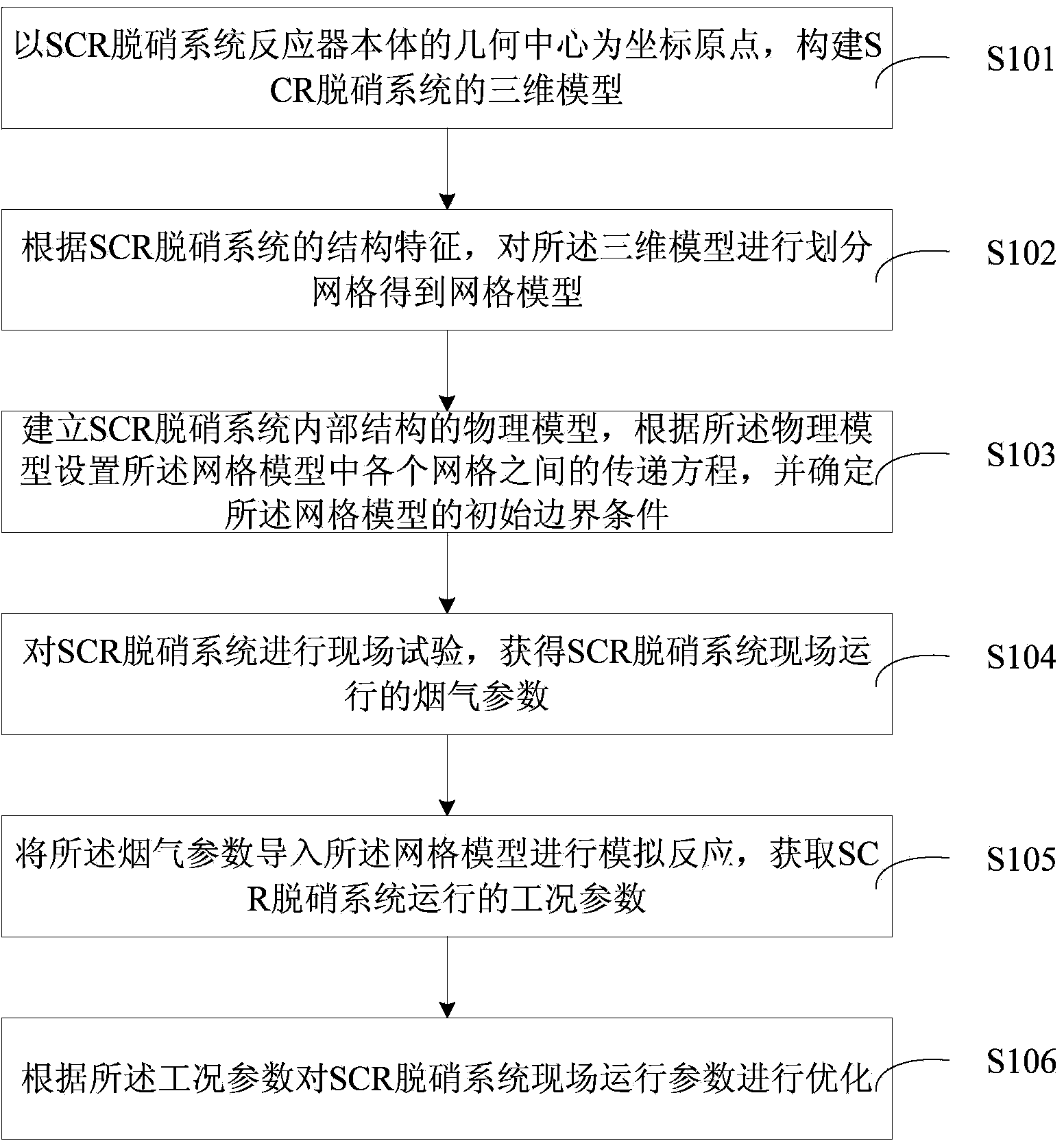

[0054] see figure 2 as shown, figure 2 It is a flow chart of the on-site operation optimization method of the SCR denitrification system of an embodiment, which mainly includes the following steps:

[0055] Step S101, taking the geometric center of the reactor bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com