Multiphase direct-current uncoupling integrated inductor

An integrated inductance, non-coupling technology, applied in the field of inductance, can solve the problems of large size and heavy equipment, and achieve the effect of reducing the volume of the magnetic core, obvious benefits, and reducing the size and weight of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Taking the two-phase DC non-coupling integrated inductor as an example, the invention content of the multi-phase DC non-coupling integrated inductor is explained, and the method is the same for multi-phase.

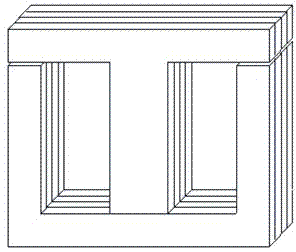

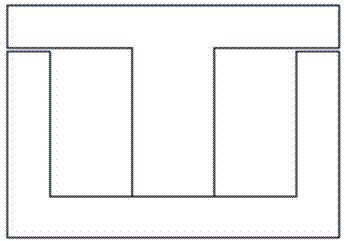

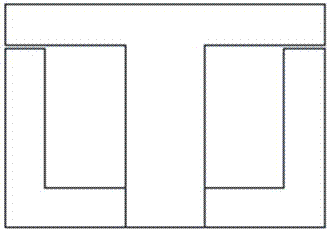

[0017] The iron core of the two-phase DC non-coupling integrated inductor is made of laminations of different shapes, such as figure 1 The structure diagram of the integrated inductor core is shown. There are two commonly used inductance core structures. The first odd-numbered layer is a UT-shaped lamination, which is composed of a U-shaped and a T-shaped lamination. The T-shaped lamination is inserted into the U-shaped lamination, such as figure 2 The structure diagram of UT-shaped laminations is shown. The second type of even-numbered layer: LLT-shaped lamination, which is composed of two L-shaped laminations and one T-shaped lamination, and the two L-shaped laminations are located symmetrically below the T-shaped lamination, such as image 3 The LLT-shaped la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com