Short-column silicon steel sheet and iron core adopting same

A silicon steel sheet and short column technology, applied in the direction of transformer/inductor core, transformer/inductor parts, inductor/transformer/magnet manufacturing, etc., can solve the problem of easy magnetic saturation, and reduce magnetic flux leakage and electromagnetic Interference, improve the effect of magnetoresistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

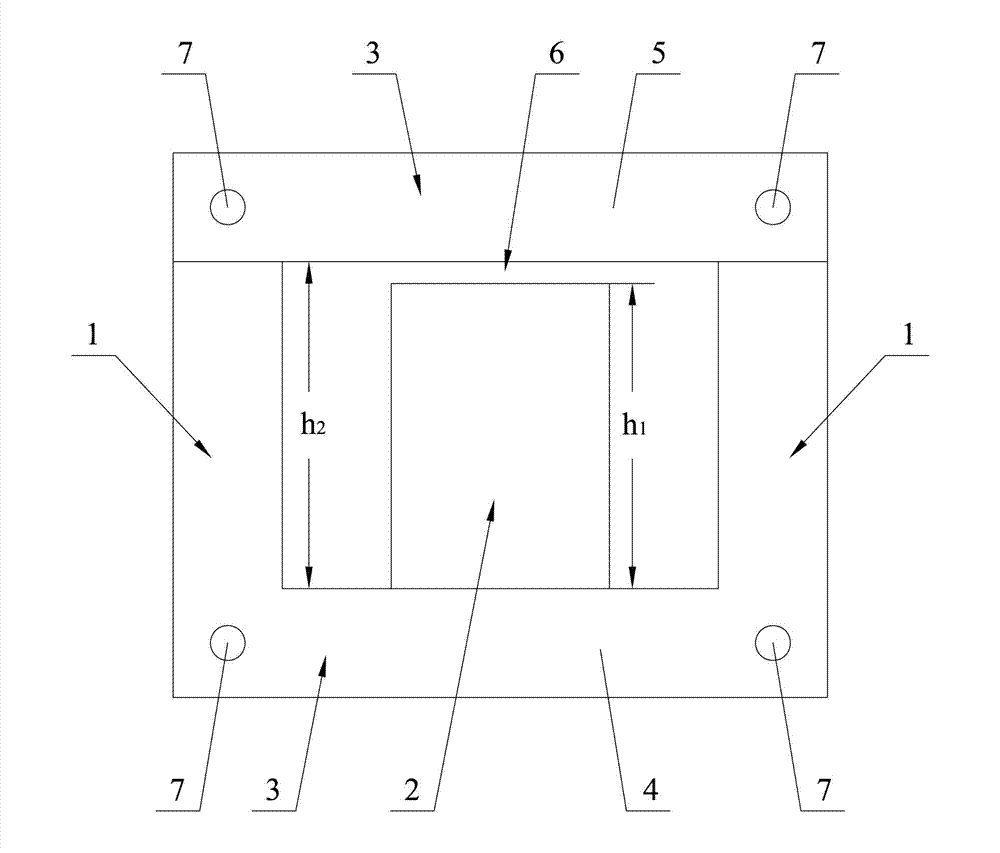

[0013] Embodiment one: see attached figure 1 shown.

[0014] A short-column silicon steel sheet, which is in the shape of a "day", includes two side columns 1, a central column 2 and two connecting pieces 3, the two side columns 1 and the central column 2 are arranged side by side, and the two side columns 1 are respectively Located on both sides of the axis of the central column 2 , two connecting pieces 3 are respectively connected to the ends of the same side of the side column 1 and the central column 2 . Usually, the short-column silicon steel sheet can be formed by splicing multiple pieces. For example, in this embodiment, the silicon steel sheet is formed by splicing E sheet 4 and I sheet 5, wherein two side columns 1, center column 2 and one connecting sheet 3 form E sheet 4, and another connecting sheet 3 forms I slice 5.

[0015] Since the central column 2 and the side column 1 are arranged side by side between two connecting pieces 3 arranged in parallel, the len...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap