Polycrystalline silicon film solar cell with electric circuit openings

A polysilicon thin film and solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as high manufacturing costs, affect battery performance, and reduce battery efficiency, so as to improve performance and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

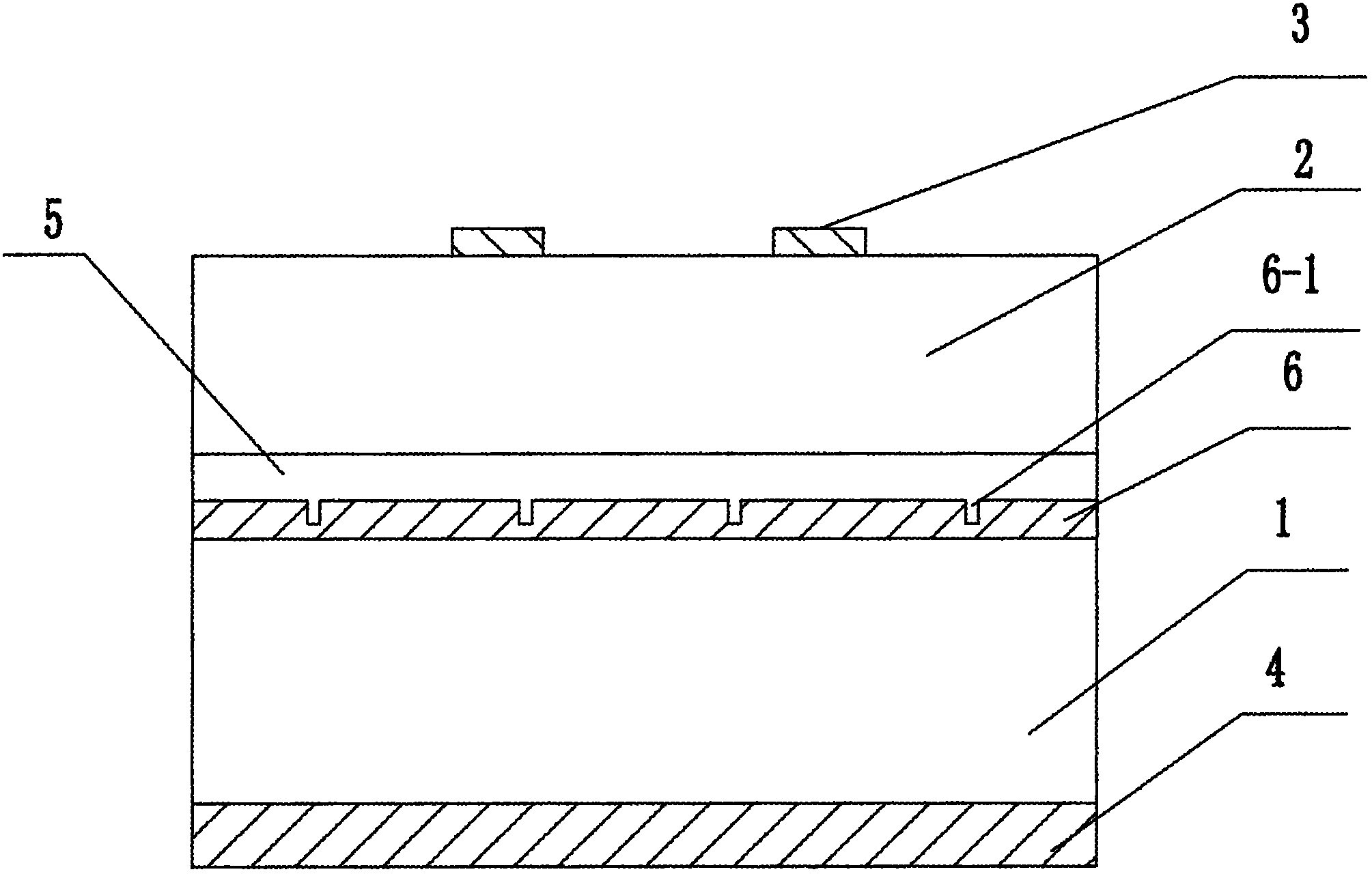

[0012] The present invention is described in further detail now in conjunction with accompanying drawing. The drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0013] Such as figure 1 A polysilicon thin-film solar cell with electrical circuit openings shown includes a substrate 1, a polysilicon thin film 2, an upper electrode 3 and a back electrode 4, a p-n junction is formed on the polysilicon thin film 2, and the substrate 1 is arranged on the back electrode 4 A heavily doped P+ layer 5 and a silicon dioxide isolation layer 6 are arranged between the substrate 1 and the polysilicon film 2, and several electrical circuit openings formed by the back electrode 4 and the upper electrode are arranged on the silicon dioxide isolation layer 6. 6-1.

[0014] The thickness of the silicon dioxide isolation layer 6 is 2 microns...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap