Concentrated seed manure gas-sending type precision seeder

A seeder and precision technology, which is applied in the directions of seeder parts, fertilizers, and seeding equipment, can solve the problems of difficulty in folding, increase in the number of working rows, unfavorable robbing of farmers, etc. Conducive to the effect of farming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the invention is described in further detail:

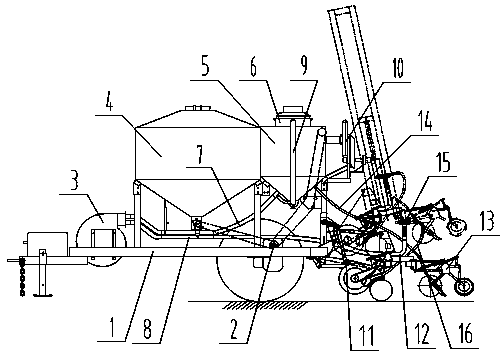

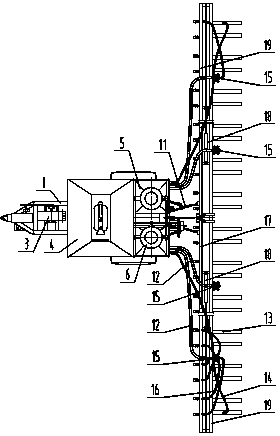

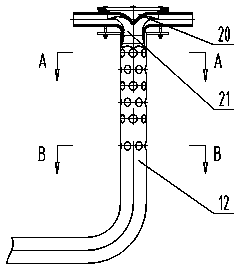

[0019] Such as figure 1 , figure 2 As shown, a schematic diagram of the specific embodiment of the concentrated fertilizer air delivery type precision seeder of the present invention is provided, including a traction frame 1 and a ground wheel transmission system 2 installed on the traction frame 1, a blower 3, and a seeder frame, and the sowing unit 13 installed on the sowing frame also includes a fertilization system and a seeding system, and a three-point suspension mechanism 11 is provided at the rear end of the traction frame 1, and the sowing frame is articulated on the three-point suspension mechanism 11, blower 3 is arranged on traction frame 1 front, and this fertilization system is made up of concentrated fertilizer box 4, fertilizer main trachea 8, fertilizer distribution pipe 12, fertilizer distributor 15, fertilizer delivery pipe 16, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com