Multifunctional milk foam cup

A multi-functional, milk foaming technology, applied in the field of cups, can solve the problems of cumbersome operation, difficult to take out and clean, complex structure, etc., and achieve the effects of sensitive and reliable control, safe use and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

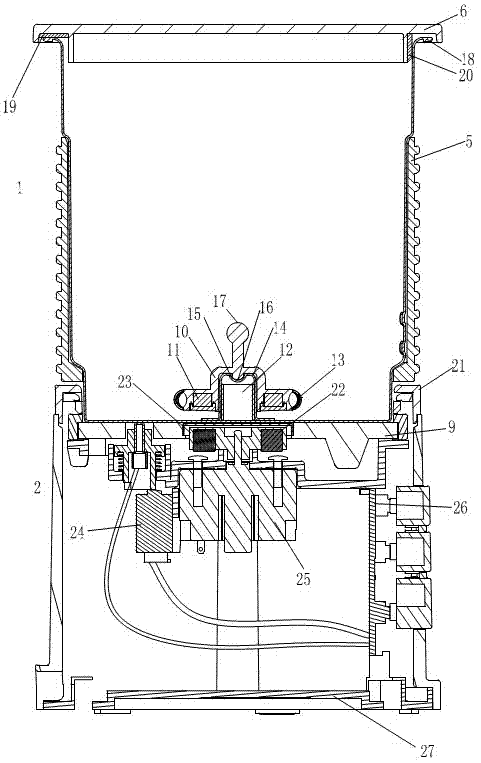

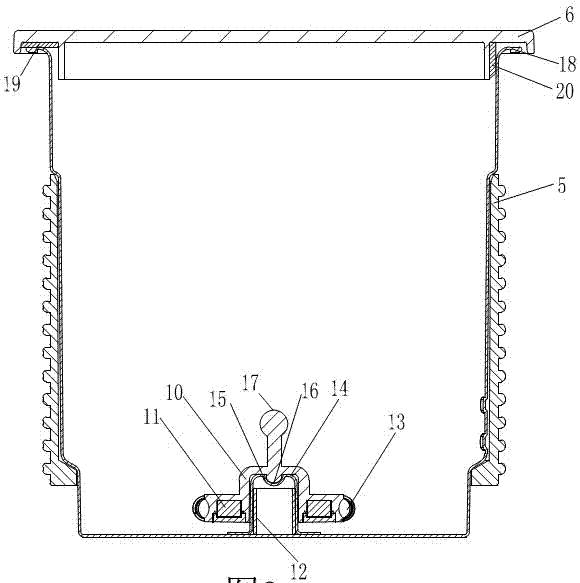

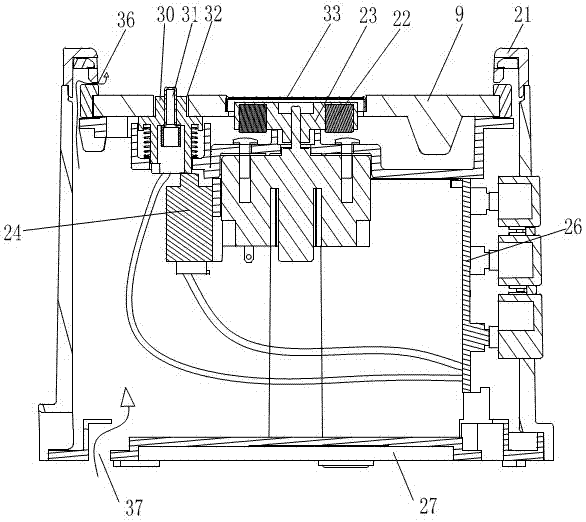

[0019] Embodiments of the present invention will be further described in detail in conjunction with the accompanying drawings.

[0020] see figure 1 As shown in FIG. 2 , the milk foam cup includes a cup body 1 and a base 2 , the cup body 1 is provided with a stirring assembly, and the base 2 is provided with an electric assembly and a temperature control assembly. The stirring assembly consists of a boss 14 arranged in the cup body 1, a rotating body 10 resting on the boss 14, stirring permanent magnets 11 on both sides of the rotating body 10, an armature 12 arranged in the boss 14 and a stirring Stirring circle 13 outside permanent magnet 11 forms. A cylindrical boss 14 is arranged in the middle of the cup body 1, and the center of the top surface of the boss 14 is provided with a concave circular hole 15, and the downwardly convex semi-spherical surface 16 in the middle of the rotating body 10 is rotatably fitted with the concave circular hole 15, The outer cylindrical su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com