Novel energy-saving type sterilizer

An energy-saving and sterilizer technology, which is applied to sanitary equipment for toilets, water supply devices, heating, etc., can solve the problems of increased energy consumption, large energy consumption, and reduced performance of sterilizers, and achieves reduced difficulty in processing and assembly , good covering and supporting performance, and the effect of reducing the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

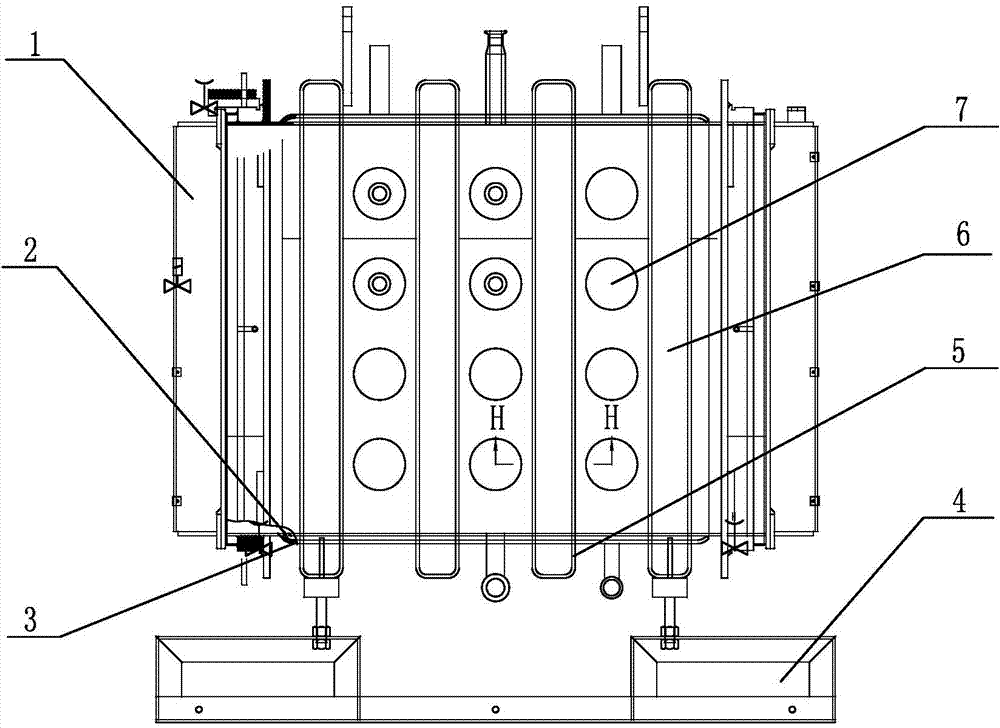

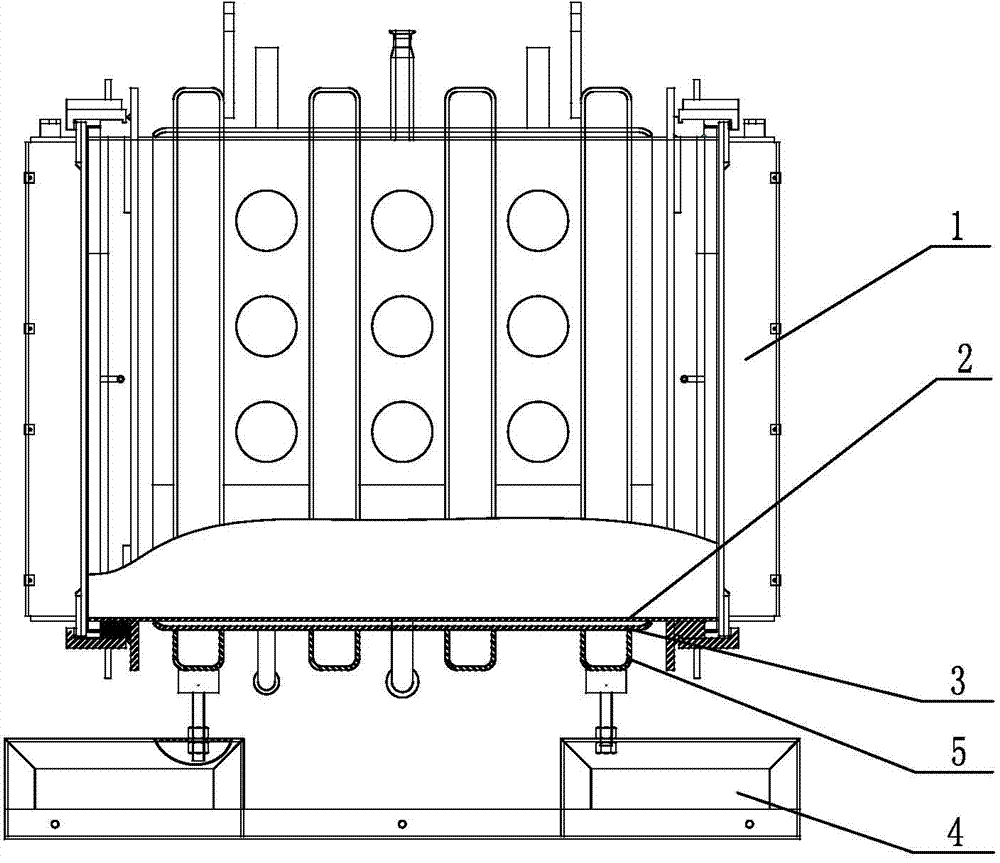

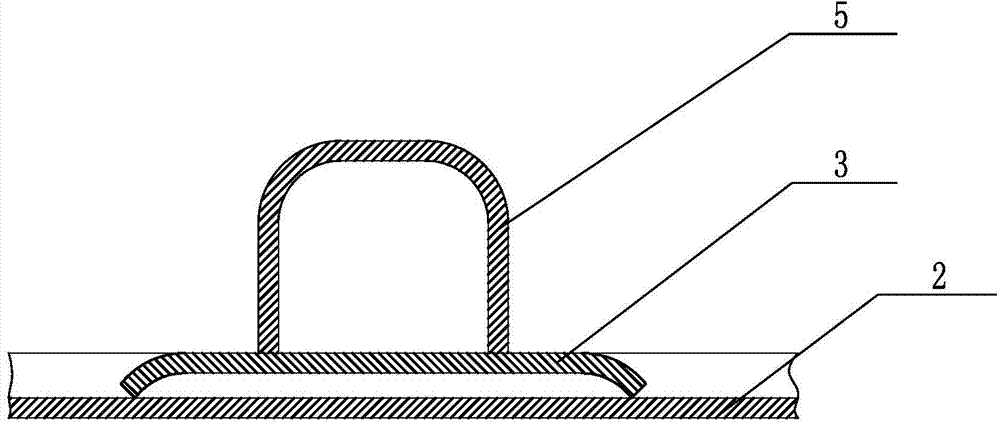

[0023] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0024] Such as Figure 1-Figure 4 As shown, the novel energy-saving sterilizer of the present invention includes a base 4 and a sterilizing main body 6, the sterilizing main body 6 is installed on the base 4, airtight doors 1 are arranged on both sides of the sterilizing main body 6, and the sterilizing main body 6 includes The inner shell 2, the outer shell 3 and the reinforcing rib 5, the inner shell 2 is a flat plate, the outer shell 3 is provided with stretching holes 7, the stretching holes 7 are arranged at equal intervals, and the depth of the stretching holes 7 is greater than 0mm and less than or equal to 30mm, corresponding The distance between adjacent stretching holes 7 is 200mm-300mm. The outer shell 3 and the inner shell 2 are welded together through the stretching holes 7, the outer shell 3 is welded with reinforcing ribs 5, the reinforcing ribs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com