Oil slinger fan blade for oil fume purifier and manufacturing method thereof

An oil fume purifier and a manufacturing method technology, which are applied in chemical instruments and methods, oil fume removal, separation methods, etc., can solve the problems of reducing the purification rate of the purifier, low purification efficiency, and large wind resistance, so as to reduce wind resistance and purification efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

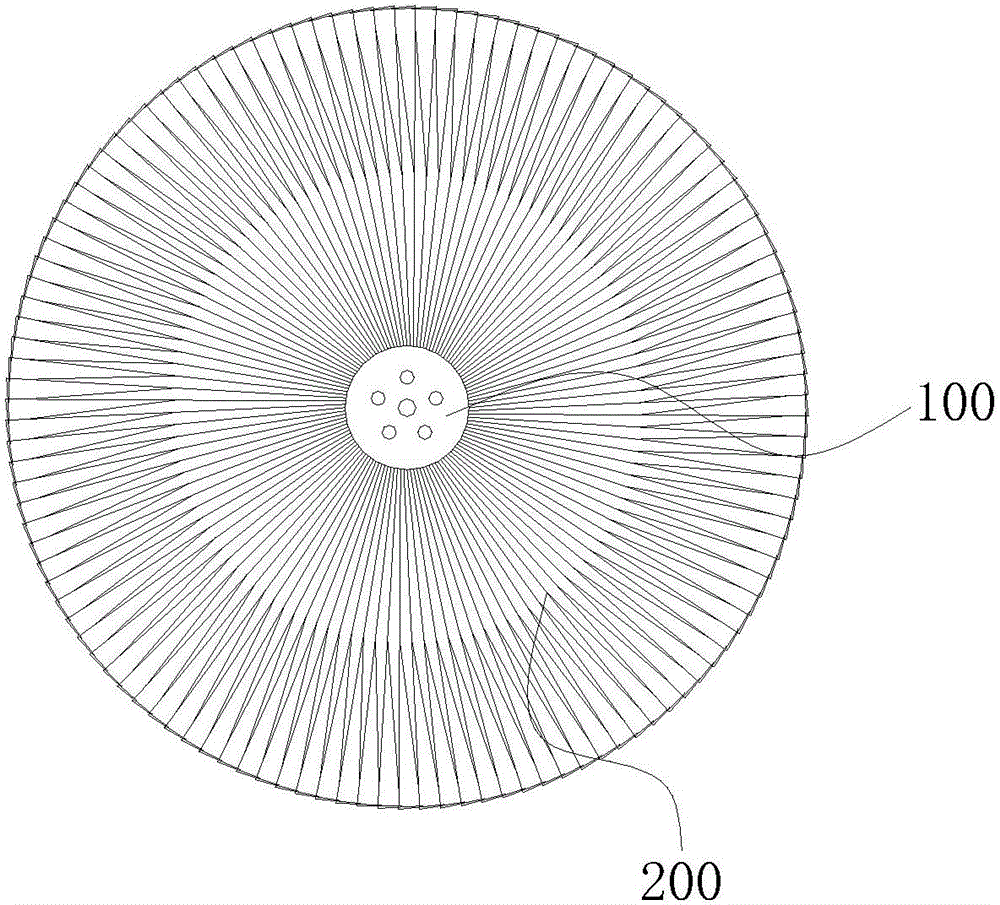

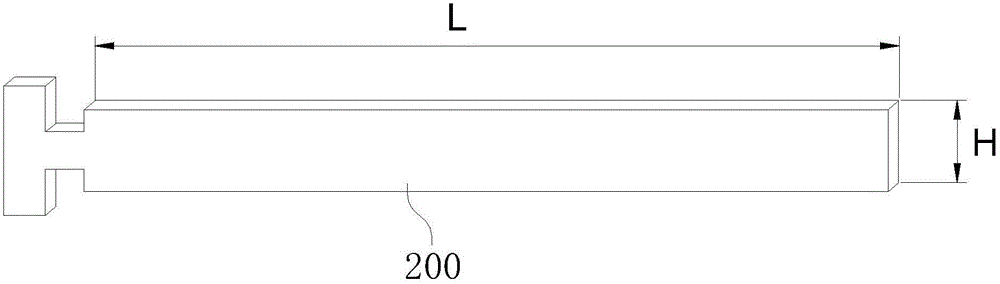

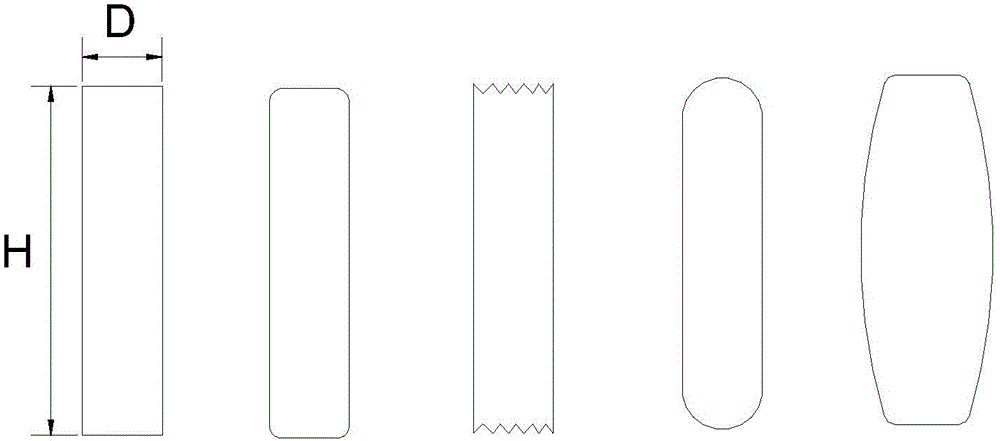

[0065] Such as Figure 1 to Figure 4 Shown is the first embodiment of the present invention used for the oil-fleeing fan blade of the oil fume purifier, as figure 1 As shown, it includes a central disk 100 and several elongated flat blades 200 radially distributed around the central disk 100. One end of these blades 200 is fixedly connected to the central disk 100, and the blades 200 are fixedly connected to the center disk 100. One end is defined as a fixed end, and the other end is defined as a free end. The ratio of the projected area of these blades 200 along the axis of the central disk 100 to the area formed by several blades 200 for blocking oil fume when the oil flinger blade rotates is K1,70 %≤K1≤100%. Wherein, these vanes 200 are flat, that is, the ratio S2 of the height H of the cross section perpendicular to the length direction of the vanes 200 to the thickness D of the vanes 200 is greater than 1. In this embodiment, S2≥1.5, and the height H is calculated. Th...

Embodiment 2

[0076] Such as Figure 5 Shown is the second embodiment of the dynamic physical interception purifier of the present invention, which is used to be installed on the rotating shaft to intercept and separate grease and / or solid particles in the oil fume, such as Figure 5 As shown, it includes a central disk 100 and several elongated flat blades 200 distributed radially or divergently around the central disk 100. One end of these blades 200 is fixedly connected to the central disk 100, and the blades 200 are fixedly connected to the center. One end of the disk 100 is defined as a fixed end, and the other end is defined as a free end. The value of the product of the thickness D of the blade 200 and the number n of blades 200 is S1, 10≤S1≤600, and the unit of the thickness D is millimeters during calculation. n is a natural number, and D≥0.2mm. Wherein, these vanes 200 are flat, that is, the ratio S2 of the height H of the cross section perpendicular to the length direction of th...

Embodiment 3

[0100] Such as Figure 6 to Figure 7 Shown is the third embodiment of the present invention for the oil throwing fan blade of the oil fume purifier, as Figure 6 As shown, it includes a central disk 100 and several elongated flat blades 200 radially distributed around the central disk 100. One end of these blades 200 is fixedly connected to the central disk 100, and the blades 200 are fixedly connected to the center disk 100. One end is defined as the fixed end 210, and the other end is defined as the free end 220. The ratio of the projected area of these blades 200 along the axial direction of the central disk 100 to the area formed by several blades 200 for blocking the oil fume when the oil flinger blade rotates is K1 , 70%≤K1≤100%. Wherein, these vanes 200 are flat, that is, the ratio S2 of the height H of the cross section perpendicular to the length direction of the vanes 200 to the thickness D of the vanes 200 is greater than 1. In this embodiment, S2≥1.5, and the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com