Die assembly dedicated for production of fan cover

A technology of fan cover and die set, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the frequency of edge flat grinding and uneven distribution of blank holder force, so as to reduce the frequency of flat grinding and improve the reasonable The effect of uniformity and stability, uniform distribution of blank holder force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

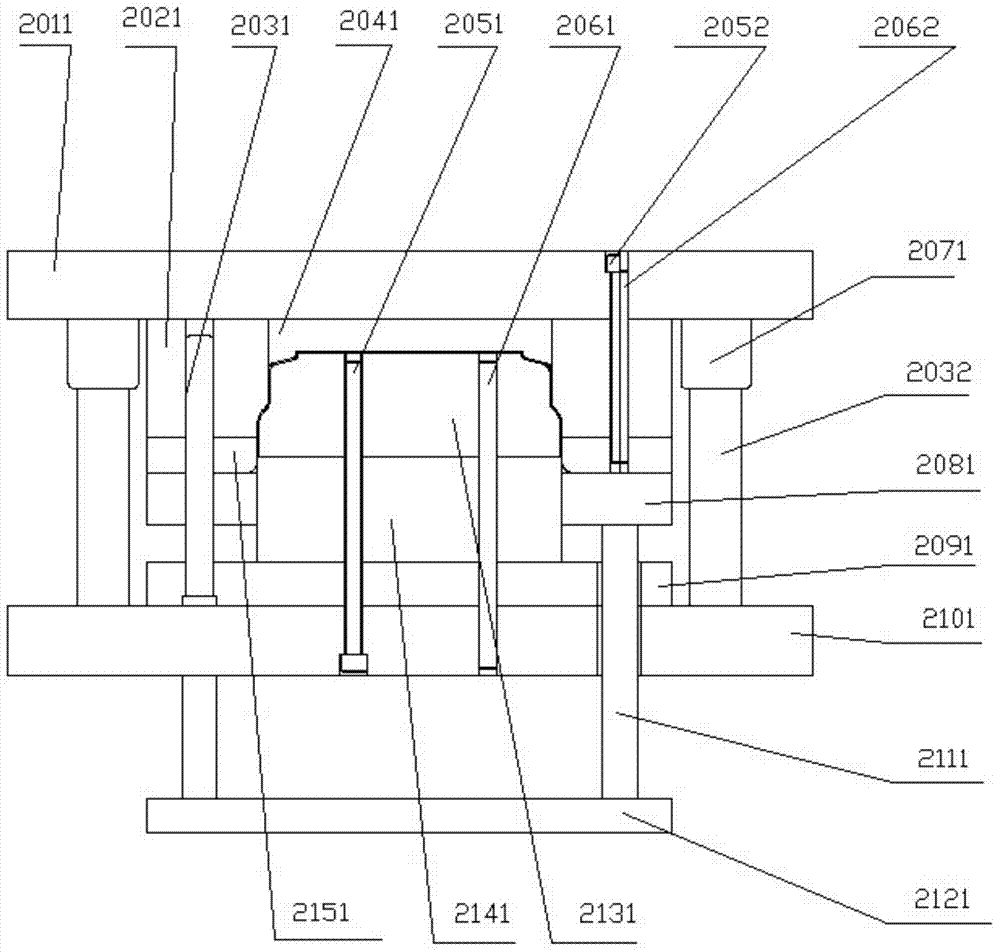

[0047] The present invention is further described below in conjunction with specific embodiment:

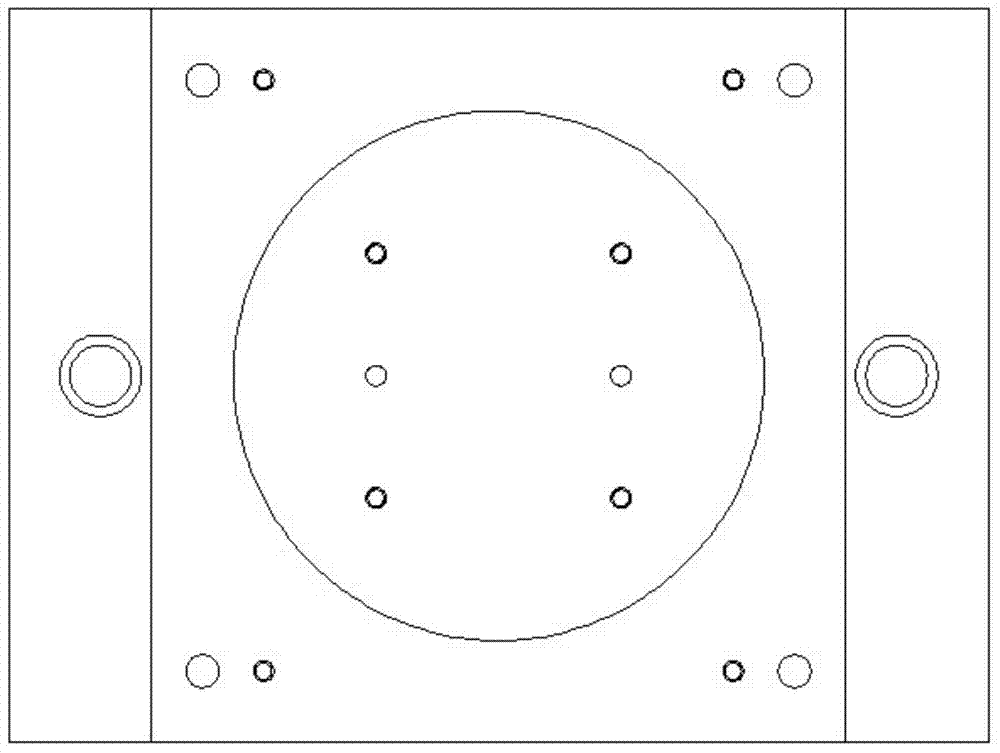

[0048] The fan cover produced by using the special mold set for the production of a fan cover is hollow cylindrical, and the lower surface is a circular opening; the upper surface is provided with 6 sets of fan-shaped surfaces with the center opening circle as the center, each There are four elongated gradient punching holes on the fan-shaped surface; four groups of arched protrusions are equidistantly distributed on the side surface, and each protrusion has a circular hole.

[0049] To achieve the above object, the present invention adopts the following technical solutions:

[0050] The special mold group for producing the fan cover, according to the sequence of its production process, includes a blanking mold, a composite mold for stretching and trimming, a punching mold for the upper surface, and a punching mold for the side surface;

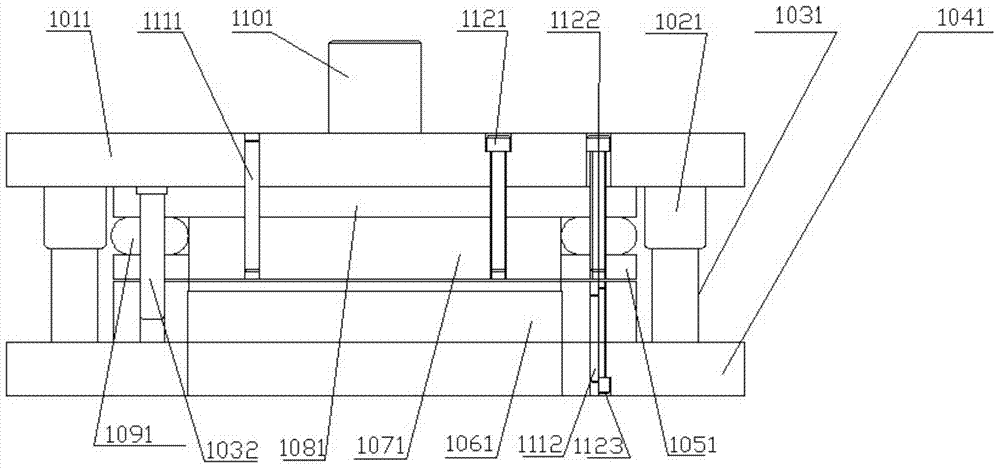

[0051] A fan cover blanking mold, compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com