Chassis mechanism for mobile welding robot

A technology of welding robots and robots, applied in the field of robots, to achieve the effects of simple control, improved driving force and stability, and large adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In conjunction with the accompanying drawings, the description is as follows:

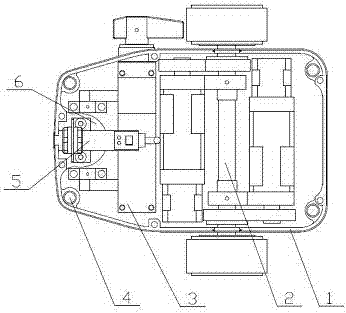

[0030] A mobile welding robot chassis mechanism according to the present invention adopts a wheel differential drive structure, including a body (1), a driving device (2), a guide wheel (6), a permanent magnetic adsorption device (3), and an obstacle avoidance device ( 5) and the anti-drop device (4); the body (1) is the installation basis of all devices.

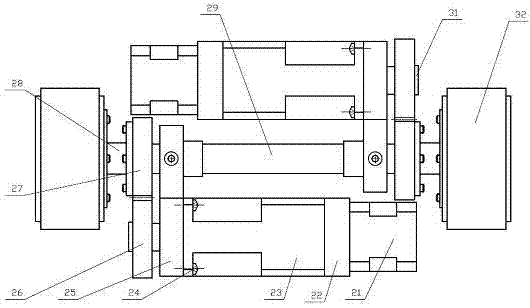

[0031] The drive device (2) includes a drive shaft (29), a drive shaft support (25), a drive motor (21), a reducer (23), a driving gear (26), a driven gear (27) and a drive wheel (21), the two drive shaft supports (25) are installed on the rear of the body (1) through connecting bolts, and the drive shaft (29) is installed between the two drive shaft supports (25) and fixed with screws; the two drive wheels ( 31) Installed on both ends of the drive shaft through the connecting sleeve (28); the drive motor (21) adopts a stepping or servo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com