Steel cord cutting machine head and tail processing method and processing equipment

A technology of steel cord and processing method, which is applied in the field of steel cord cutting machine head and tail processing and its processing equipment, which can solve the problems of long auxiliary time of equipment and achieve the effects of reducing downtime and waiting time, increasing production capacity and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

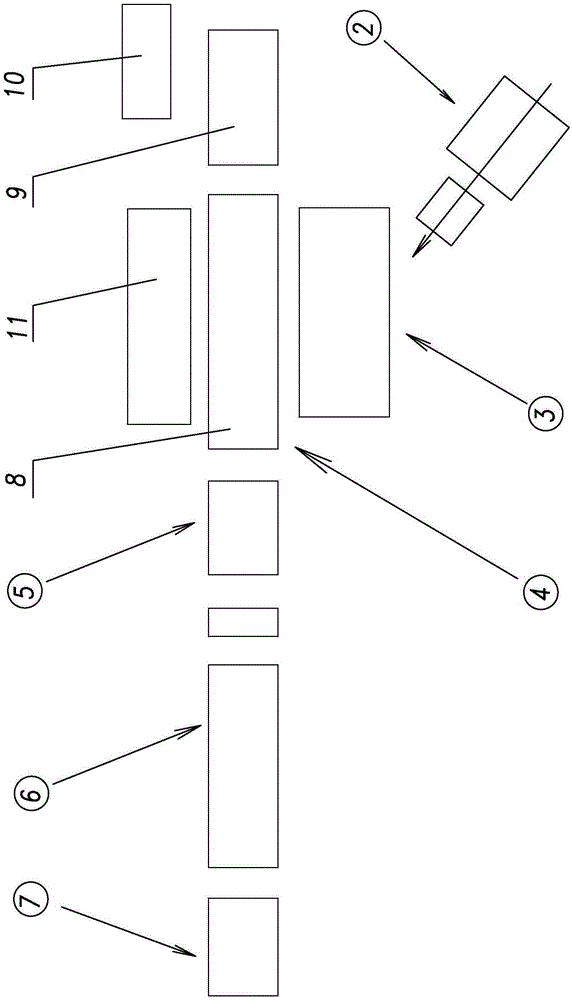

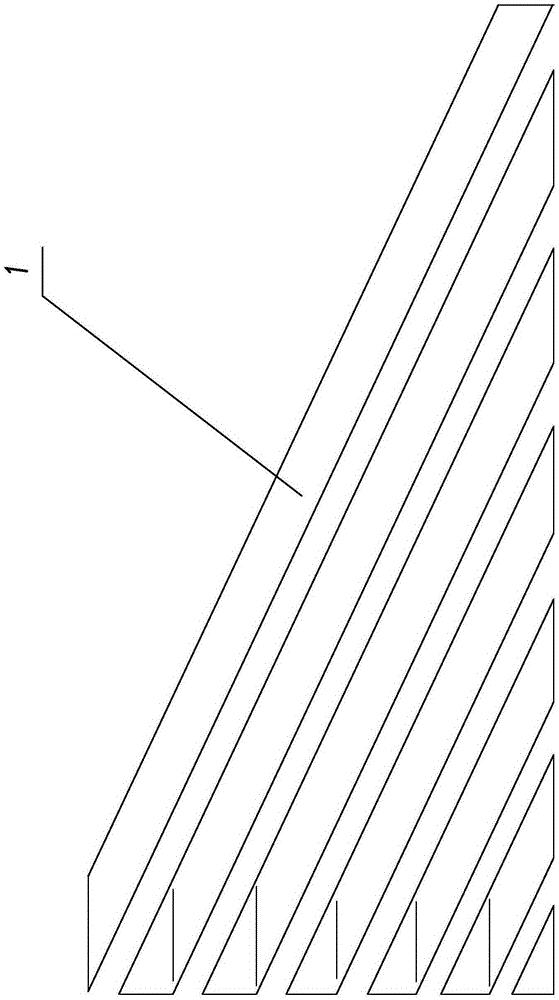

[0020] The production line process of the traditional steel cord cutting machine is: cord opening process 2, cutting process 3 (equipped with a clamping and pulling mechanism 11), conveying process 4, splicing process 5, glue wrapping process 6 and coiling process 7, among which The conveying process 4 is equipped with a cord conveyor belt 8. Under the normal production mode of the control system, the cord conveyor belt 8 runs forward, that is, the cut cord material is conveyed from the rear end (right end) to the front end (left end) in the positive direction ,Such as figure 1 shown.

[0021] The material head and tail processing equipment of the steel cord cutting machine of the present invention includes a trimming conveyor belt 9 and a louver car 10, the trimming conveyor belt 9 is arranged at the rear end of the cord conveyor belt 8, and the louve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com