Multi-objective nonlinear continuous tank diesel blending method based on pareto optimization criterion

A non-linear, multi-objective technology, applied in the petroleum industry, control/regulating systems, instruments, etc., can solve problems such as the inability to meet production equipment and production technical requirements, improve production technology and production management level, improve inventory management, Reduce the effect of retuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

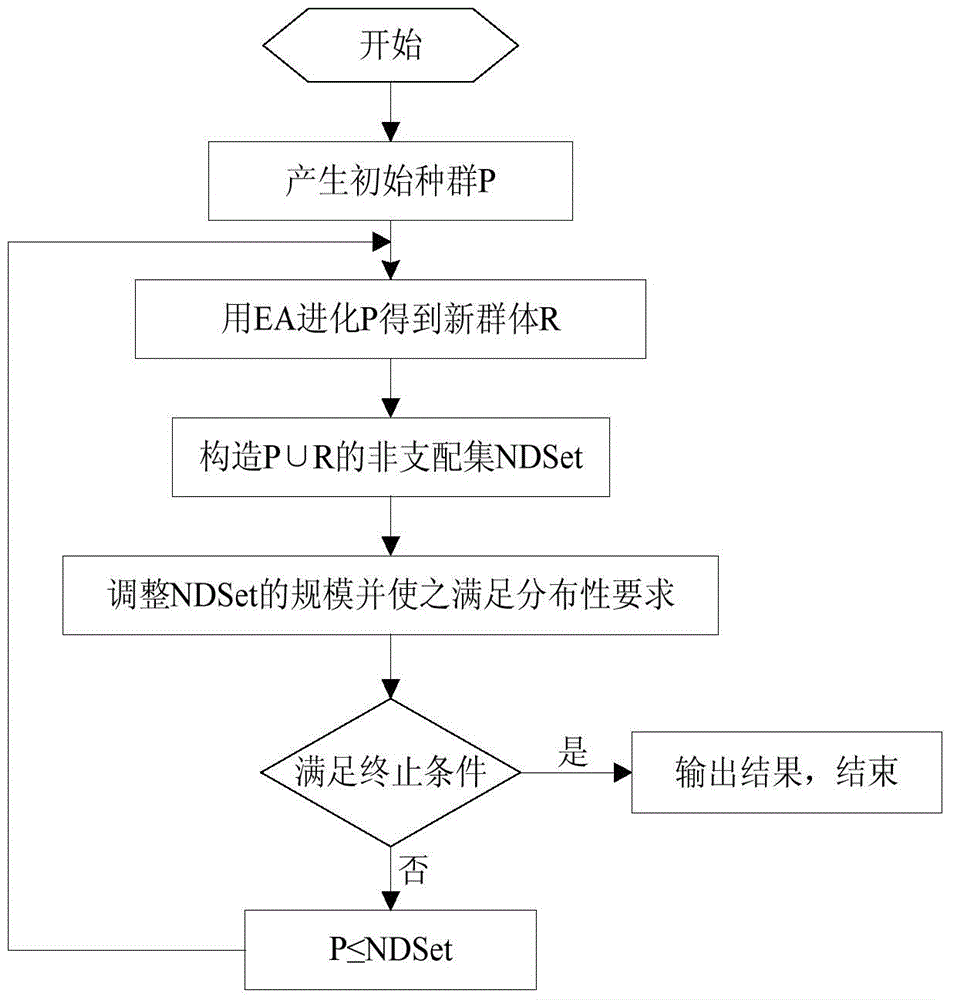

Method used

Image

Examples

Embodiment

[0072] This example is the actual production process of diesel blending of 0# vehicle diesel and 0# light diesel on a certain day in an oil refinery.

[0073] Among them, the first-line, second-line and third-line products of the two sets of atmospheric and vacuum distillation units (CDU1, CDU2) directly participate in the final blending, and the first-line products of the unit CDU2 participate in the final blending; The ratio of top reduction and first-line products to other oil products enters two sets of hydrogenation units, and the diesel components after hydrotreatment enter into the final blending; the diesel components produced by a set of lubricating oil hydrogenation units enter into the final product blending ( See CN1912072A and AIChE J.2013,59(4):1160-1174 for details).

[0074] About the production process of real oil refinery diesel oil, its process flow model please see in the specification sheet accompanying drawing of CN1912072A figure 1 .

[0075] The total...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com