Grease composition for automobile wheel hub bearings and its preparation method

An automobile wheel hub and bearing lubrication technology, applied in the field of grease, to achieve the effect of extending the service life of the bearing, short lubrication life and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

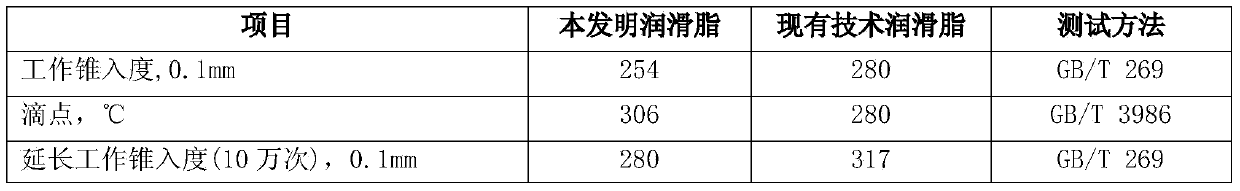

Examples

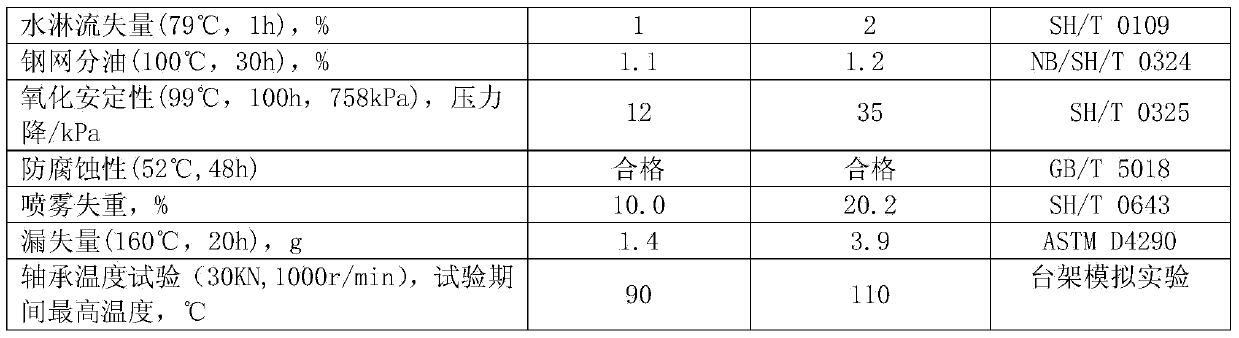

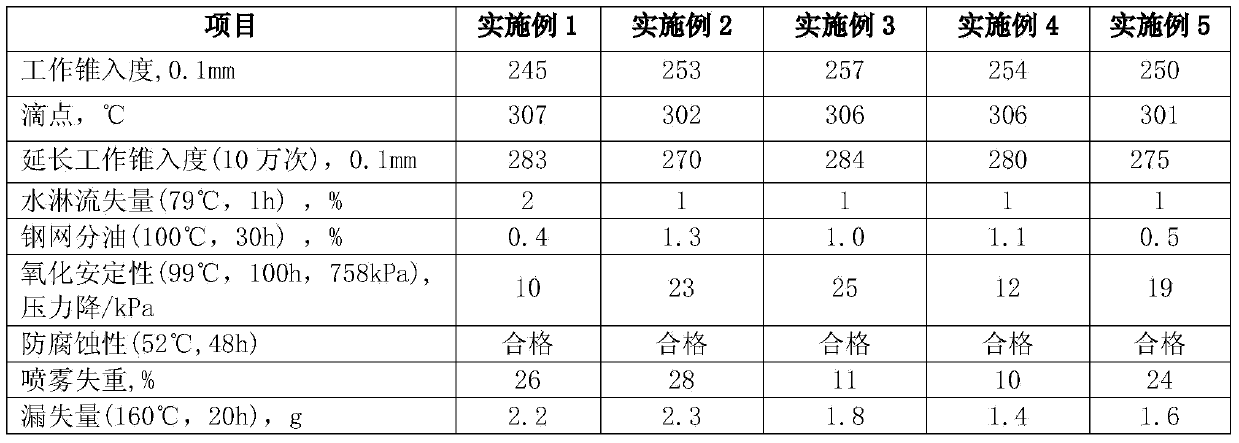

example 1

[0034] Example 1: Each component is calculated based on the total weight of the composition, including:

[0035] (1) Base oil 86.0%;

[0036] (2) Thickening agent 13.0%;

[0037] (3) Antioxidant 0.5%.

[0038] (4) Tackifier 0.5%

[0039] Calculate based on the total amount of the above components as 100%, add 0.3‰ of metal deactivator

[0040] Combine 300 g of 12-hydroxystearic acid, 50 g of azelaic acid, 25 g of sebacic acid and 1200 g of base oil (flash point of 270℃, viscosity of 180mm at 40℃) 2 / s) Put it into a pressure reactor, heat it to 90-100°C, and add 75.5 g of lithium hydroxide monohydrate aqueous solution. Warm up to 120-140℃ to start timing saponification. After 120min of saponification, release the pressure and add 600g of base oil, heat to 130-150℃, perform compound reaction for 60min, continue heating to 200-220℃, use 600g of base oil Cool in the reactor. After cooling, the temperature is controlled at 150-190℃ and the temperature is kept for 60min. Add the remaining 5...

example 2

[0041] Example 2: Each component is calculated based on the total weight of the composition, including:

[0042] (1) Base oil 85.0%;

[0043] (2) Thickening agent 14.0%;

[0044] (3) Antioxidant 0.5%.

[0045] (4) Tackifier 0.5%

[0046] Calculate based on the total amount of the above components as 100%, add 0.3‰ of metal deactivator

[0047] Combine 225 g of 12-hydroxystearic acid, 85 g of 1,10 sebacic acid and 909 g of base oil (flash point of 260℃, viscosity of 150mm at 40℃) 2 / s) Put it into a pressure reactor, heat it to 90-100°C, and add an aqueous solution of 55.6 g monohydrate lithium hydroxide and 7.9 g calcium hydroxide. Warm up to 120-140℃ to start timing saponification. After 120min of saponification, release the pressure and add 455g of base oil, heat up to 130-150℃, perform compound reaction for 60min, continue heating to 200-220℃, use 455g of base oil Cool in the reactor. After cooling, the temperature is controlled at 150-190℃ for 60min. Add the remaining 447g base oil...

example 3

[0048] Example 3: Each component is calculated based on the total weight of the composition, including:

[0049] (1) Base oil 84.0%;

[0050] (2) Thickening agent 15.0%;

[0051] (3) Antioxidant 0.5%.

[0052] (4) Tackifier 0.5%

[0053] Calculate based on the total amount of the above components as 100%, add 0.3‰ of metal deactivator

[0054] Combine 250 g of hydrogenated castor oil, 60 g of sebacic acid and 824 g of base oil (flash point of 280℃, viscosity of 250mm at 40℃) 2 / s) Put it into a pressure reactor, heat it to 90-100°C, and add an aqueous solution of 50.9 g monohydrate lithium hydroxide and 7.8 g calcium hydroxide. Warm up to 120-140℃ to start timing saponification. After 120min of saponification, release the pressure and add 412g of base oil, heat to 130-150℃, perform compound reaction for 60min, continue heating to 200-220℃, use 412g of base oil Cool in the reactor. After cooling, the temperature is controlled at 150-190℃ and the temperature is constant for 60min. Add th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com