Roller bottom type continuous heating furnace for track shoe

A roller hearth heating furnace technology, applied in heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of furnace door falling, difficulty in ensuring the alignment and rolling out of workpieces, and difficulty in determining the opening and closing time of the furnace door, so as to shorten the time , avoid temperature drop, reduce the effect of overflow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

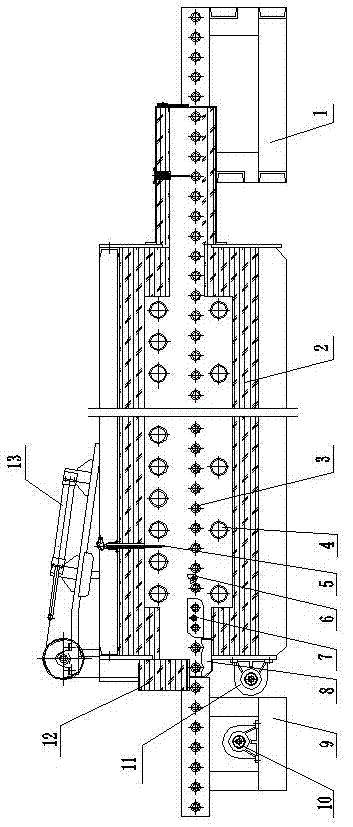

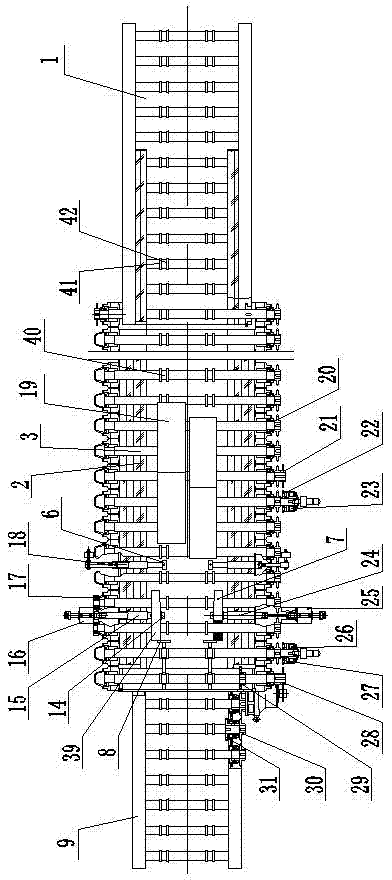

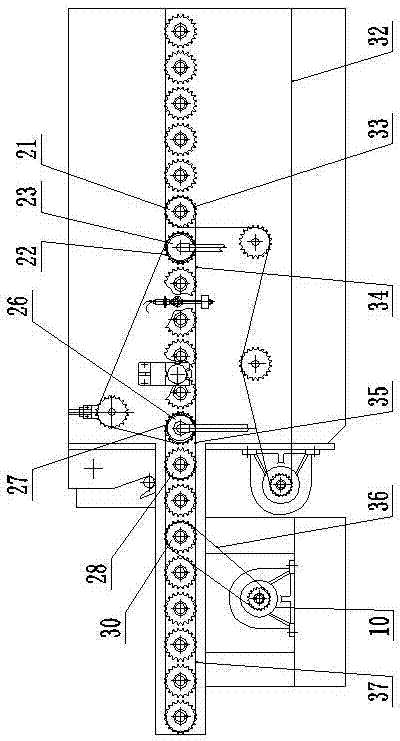

[0026] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0027] A crawler roller hearth type continuous heating furnace, as shown in the figure, it includes a furnace body 2 with a furnace door 12 and a casing, and a feeder 1 and a discharger 9 positioned at two ends of the furnace body 2, the feeder Each transmission roller 3 of the transmission mechanism in the feeder 1 , the discharger 9 and the furnace body 2 is provided with at least two guide grooves 40 for making the workpieces 19 run in a row. The guide groove 40 includes an inner limit ring 42 and an outer limit ring 41 . Wherein, on the two adjacent drive rollers 3 located at the outlet end of the heating part in the furnace body 2, the outer limit ring 41 adopts a limit device for closing or opening the guide groove 40; The detection device for the signal, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com