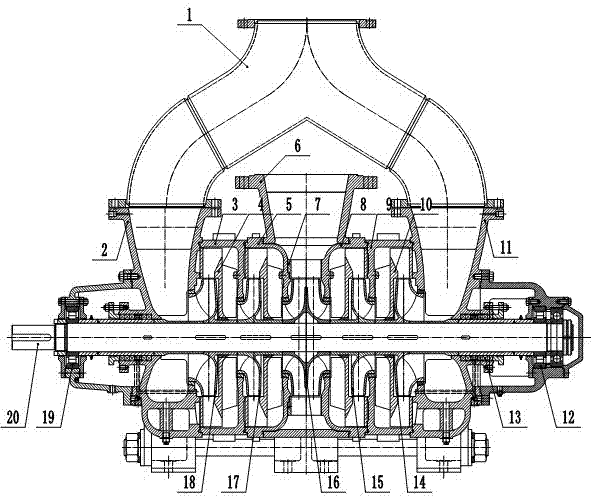

Parallel type self-balancing multi-stage centrifugal pump

A self-balancing, centrifugal pump technology, applied in the field of centrifugal pumps, can solve problems such as head range and cavitation performance that are difficult to meet, and achieve the effects of prolonging trouble-free working time, excellent cavitation performance, and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Such as figure 1 As shown, a parallel self-balancing multistage centrifugal pump includes a pump body 5 and a main shaft 20. A shaft seal device 13 is provided on both sides of the main shaft 20. The main shaft 20 passes through a left bearing body part 19 and a right bearing body part. 12 is fixed on the pump body 5, the positive front impeller 18, the positive impeller 17, the positive guide vane 4, the reverse impeller 15, the reverse guide vane 10 and the reverse front impeller 14 are arranged symmetrically back to back on the main shaft, and the middle impeller 16 And the middle guide vane 7 is installed in the middle of the main shaft 20, the positive front impeller 18, positive impeller 17 and positive guide vane 4 are located in the left middle section 3 of the pump body, and the reverse front impeller 14, reverse impeller 15 and Anti-guide vanes 10 are located in the right middle section 9 of the pump body.

[0012] When the water pump is running, the water is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com